Hydro-upgrading method for ungraded gasoline

A technology for hydro-upgrading and inferior gasoline, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve problems such as low desulfurization rate, achieve high hydrodesulfurization, reduce olefin saturation rate, and improve aromatization Effects of chemoselectivity and octane retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

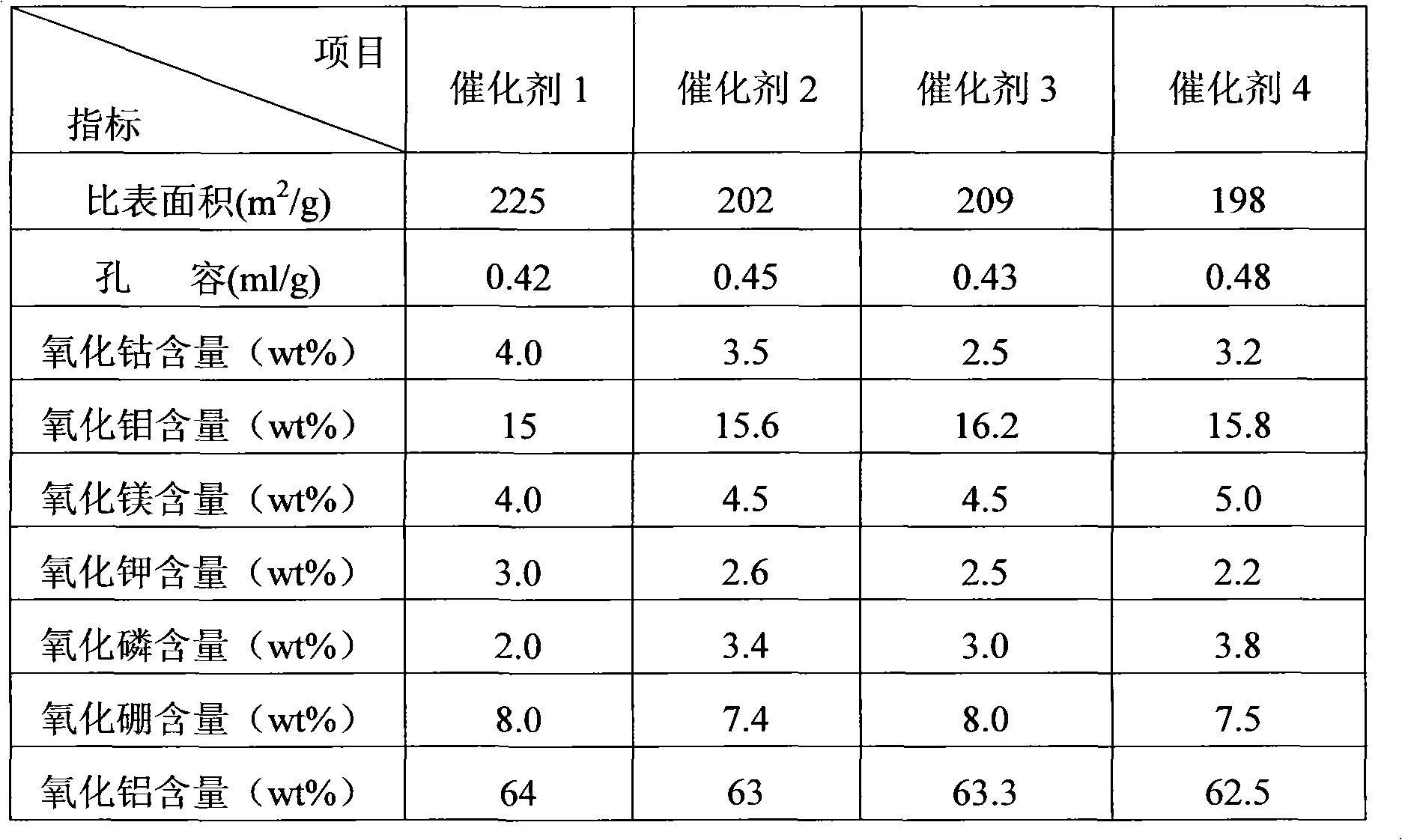

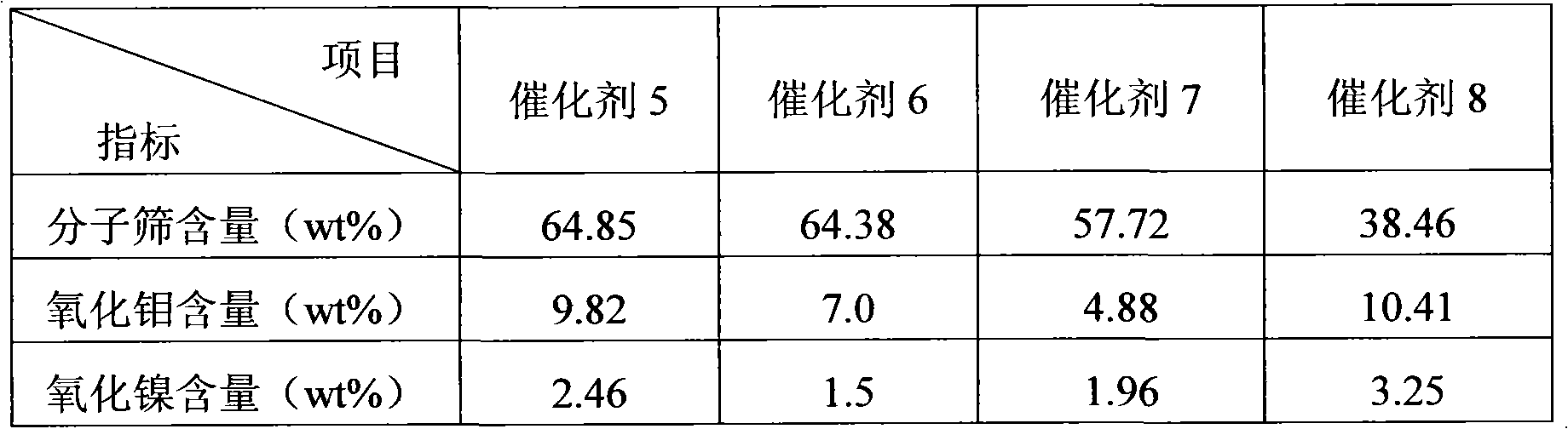

[0053] Preparation of selective hydrodesulfurization catalysts 1-4:

[0054] Preparation of Catalyst 1:

[0055] Mix SB powder, boron oxide and squash powder evenly, add nitric acid and water, knead and shape, dry at 120°C, and roast at 520°C for 4 hours to obtain a composite oxide carrier.

[0056] Prepare a suitable mixed impregnation solution of magnesium nitrate, potassium nitrate and diammonium hydrogen phosphate, impregnate the composite oxide carrier, age at room temperature for 6 hours, dry at 120°C for 3 hours, and roast at 530°C for 4 hours to obtain a catalyst modified with additives magnesium, potassium and phosphorus carrier.

[0057] Prepare a mixed solution of cobalt nitrate and ammonium molybdate with an appropriate concentration at a temperature of 70°C, add ammonia water to dissolve it completely, and then impregnate it on a catalyst carrier modified with additives magnesium, potassium and phosphorus, and age it at room temperature for 8 hours, 120 °C for 4...

Embodiment 1

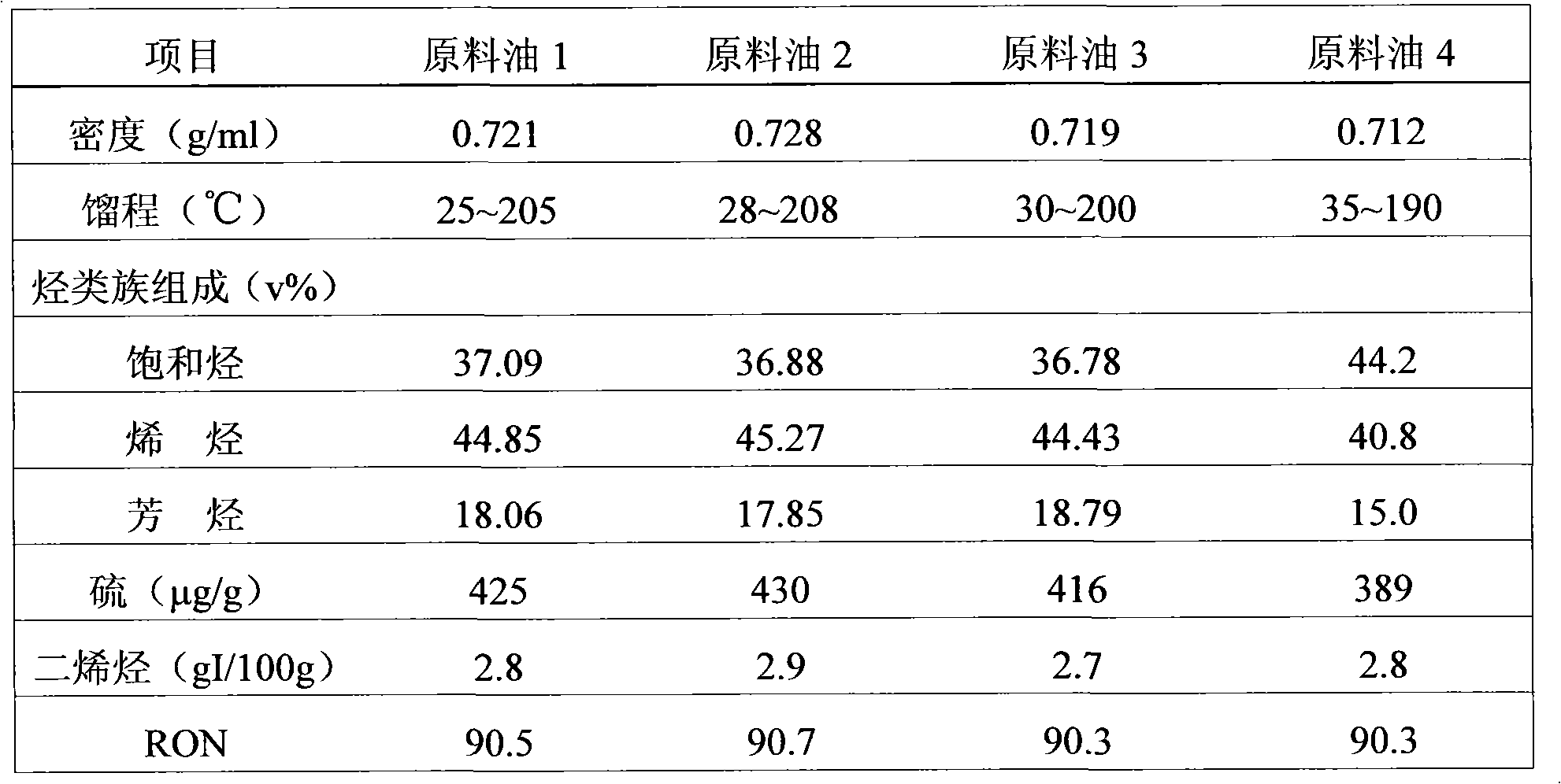

[0094] The hydro-upgrading treatment adopts an adiabatic fixed bed, and two reactors are connected in series. The selective hydrodesulfurization catalyst 1 is loaded in the first reactor; the octane recovery catalyst 5 is loaded in the second reactor. Raise the temperature at 50°C / h to 150°C, and feed naphtha (containing 2wt% CS 2 ) sulfuration treatment for 1 hour, and then sulfuration treatment at 230° C., 290° C. and 320° C. for 6 hours respectively to complete the sulfuration treatment of the catalyst.

[0095] After the vulcanization treatment is completed, switch to full fraction FCC raw material gasoline 1, at a reaction pressure of 1.2MPa and a volume space velocity of 4.0h -1 , under the condition of hydrogen-oil ratio of 250, the inlet temperature of the first-stage reactor is controlled at 185°C, and the inlet temperature of the second-stage reactor is controlled at 300°C. After running for 800 hours, sample and analyze the composition of upgraded products, sulfur ...

Embodiment 2

[0097] The hydro-upgrading treatment adopts an adiabatic fixed bed, and two reactors are connected in series. The selective hydrodesulfurization catalyst 2 is loaded in the first reactor; the octane recovery catalyst 6 is loaded in the second reactor. The vulcanization treatment method is the same as in Example 1.

[0098] After the vulcanization treatment is completed, switch to full fraction FCC raw material gasoline 2, at a reaction pressure of 1.5MPa and a volume space velocity of 4.0h -1 , under the condition of hydrogen oil ratio of 300, the inlet temperature of the first-stage reactor is controlled at 190°C, and the inlet temperature of the second-stage reactor is controlled at 295°C. After running for 800 hours, sample and analyze the composition of upgraded products, sulfur content, octane number and liquid yield every 24 hours. The results are shown in Table 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com