Gasoline desulfurization method

A gasoline and heavy gasoline technology, applied in the petroleum industry, processing hydrocarbon oil, hydrocarbon oil treatment products, etc., can solve the problem of gasoline octane number loss and achieve the effect of reducing sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0043] In a specific embodiment, based on the dry weight of the adsorption desulfurization catalyst and based on the weight of the oxide, the zinc oxide in the adsorption desulfurization catalyst accounts for 10-90% by weight, and the silica accounts for 5-85% by weight. %, alumina accounts for 5-30% by weight; based on the dry basis weight of the adsorption desulfurization catalyst and based on element weight, the content of the desulfurization active metal in the adsorption desulfurization catalyst is 5-30% by weight.

[0044] A specific implementation of the present invention will be provided below in conjunction with the accompanying drawings, but the present invention is not limited thereby.

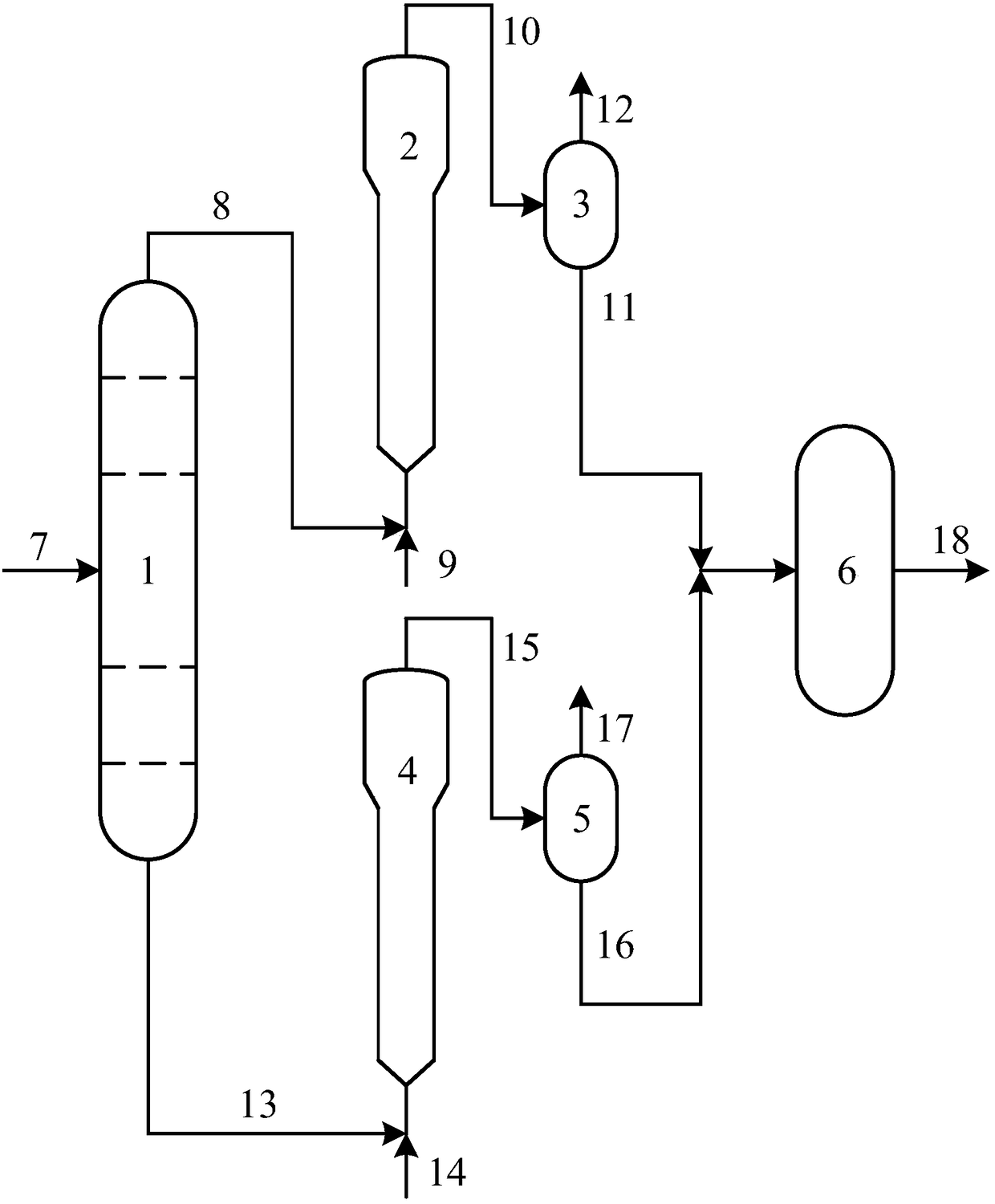

[0045] Such as figure 1 As shown, the gasoline fraction enters the gasoline raw material cutting tower 1 through the line 7, and the light gasoline fraction obtained at the top of the tower is introduced into the first set of fluidized reactor 2 through the line 8, and is mixed with the ...

Embodiment 1

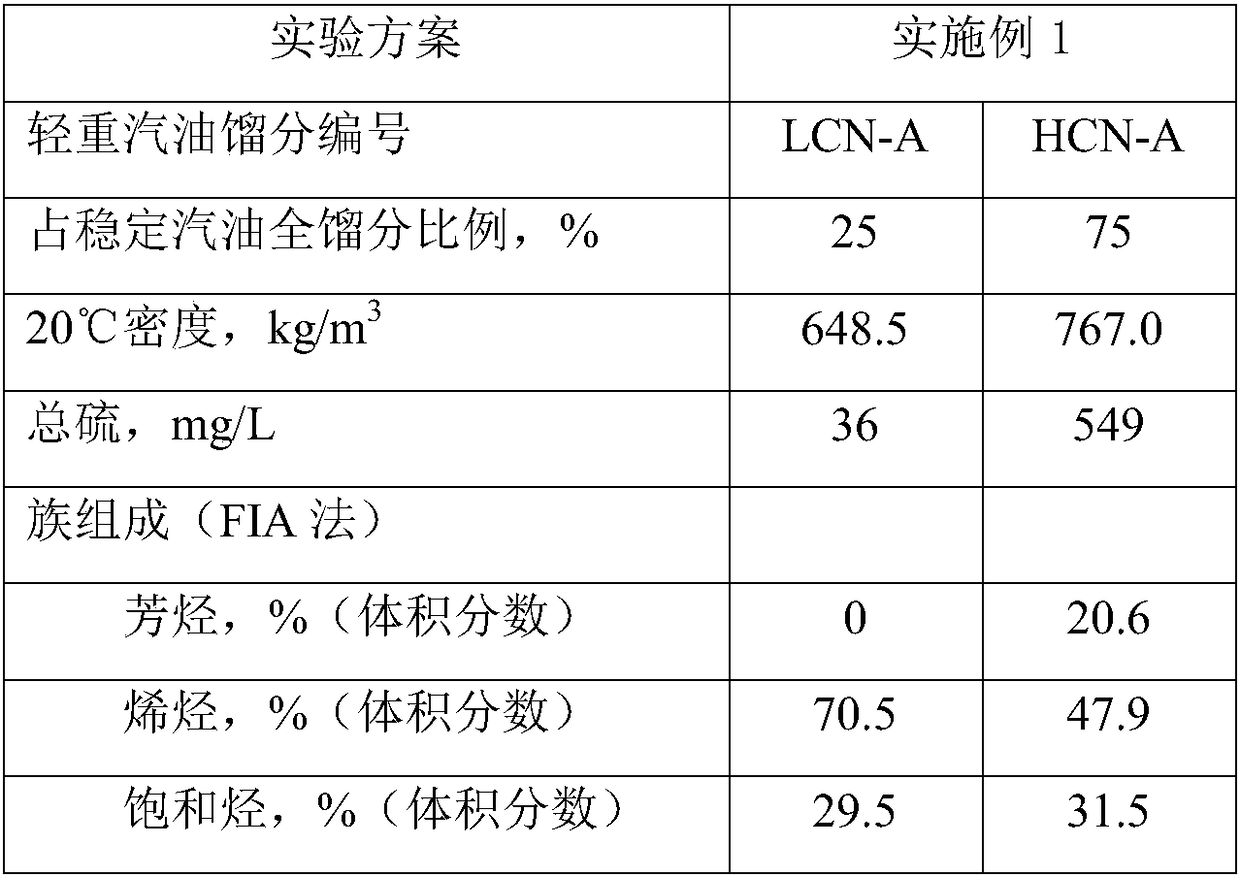

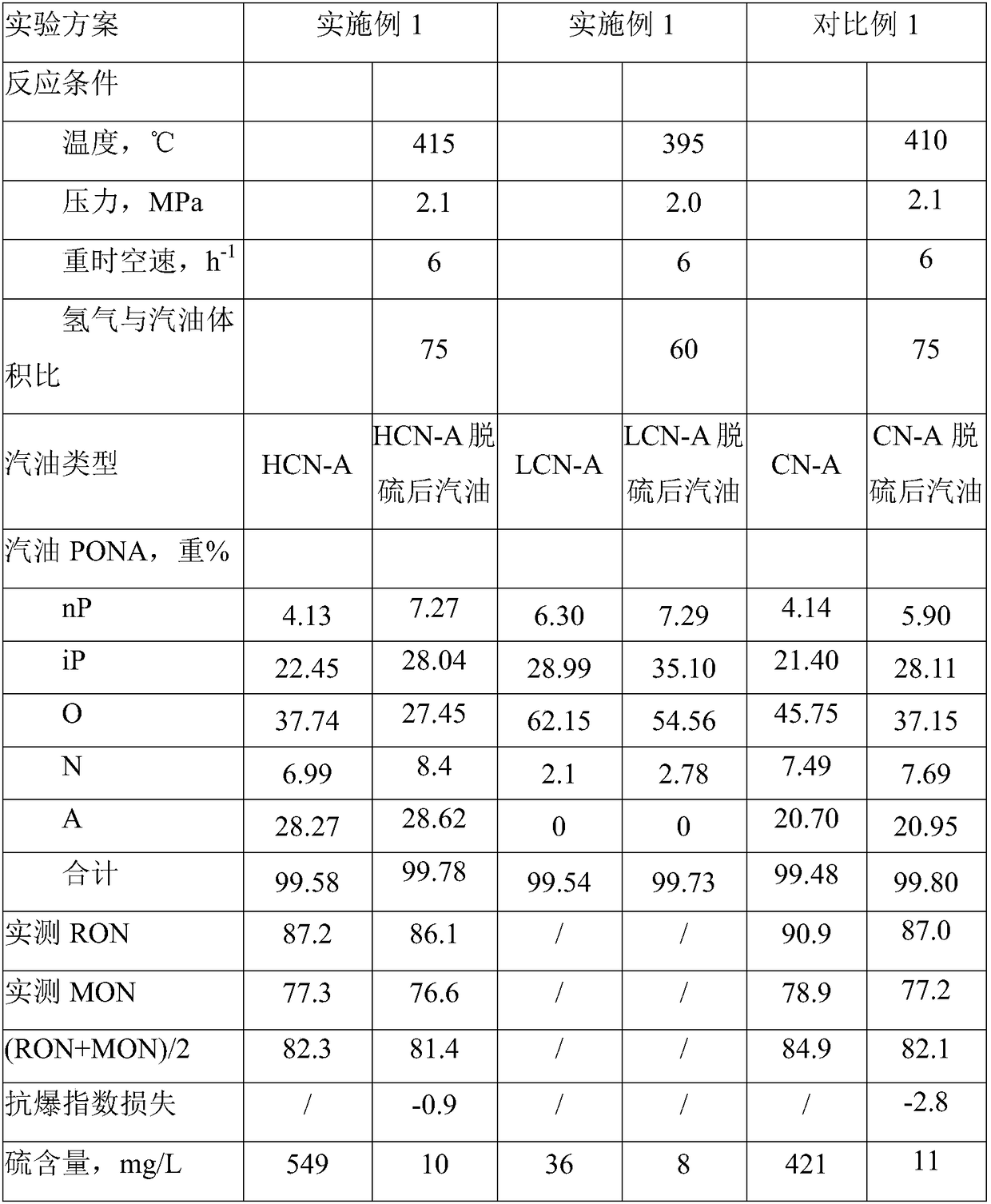

[0052] The gasoline fraction used in Example 1 is refinery stable gasoline A, and its properties are listed in Table 1. Such as figure 1 As shown, the stable gasoline A is distilled in the gasoline raw material cutting tower 1 to cut into light gasoline fraction and heavy gasoline fraction, and the final boiling point of the first light gasoline fraction is controlled to be 65-70°C (according to ASTM D86 standard). Among them, the light gasoline fraction obtained by cutting stable gasoline A is recorded as LCN-A, and the heavy gasoline fraction is recorded as HCN-A, and the properties are listed in Table 2. The heavy gasoline fraction HCN-A is sent to the first set of fluidization reactor 4 Contact with the adsorption desulfurization catalyst FCAS and carry out the first desulfurization reaction in the presence of hydrogen. The reaction conditions are listed in Table 4. The reaction product obtained from the top of the reactor is cooled and separated to obtain the tail gas and...

Embodiment 2

[0054] The operation of Example 2 is basically the same as that of Example 1, except that the temperature of the second desulfurization reaction is controlled to 410° C. to obtain a gasoline product. The properties are shown in Table 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com