A catalytic cracking catalyst

A catalytic cracking and catalyst technology, applied in catalytic cracking, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of reducing zeolite selectivity, destroying zeolite structure, high Y-type zeolite, etc., and achieve high heavy oil conversion activity, high The effect of heavy oil conversion ability and high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

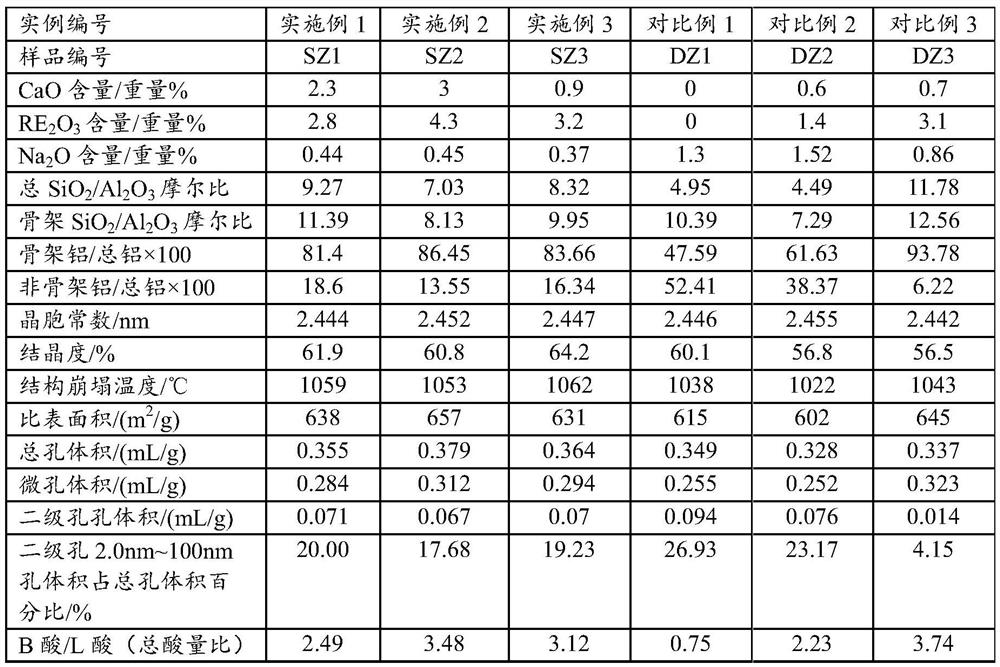

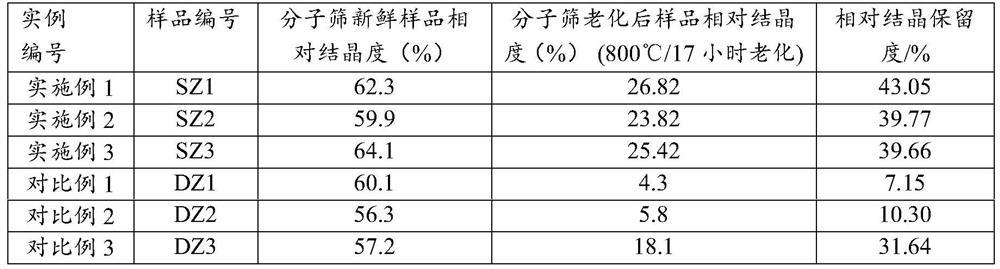

[0048] In the catalytic cracking catalyst preparation method provided by the present invention, the preparation method of the modified Y-type molecular sieve, an embodiment comprises the following steps:

[0049] (1) Perform ion exchange reaction on a mixed solution of NaY molecular sieve (also known as NaY zeolite) and soluble calcium salt and rare earth salt, filter and wash to obtain Y-type molecular sieve with calcium and rare earth conventional unit cell size with reduced sodium oxide content ; The ion exchange is usually exchanged for 30-120 minutes under the conditions of stirring and a temperature of 15-95° C., preferably 65-95° C.;

[0050] (2) Calcium-containing and rare earth-containing conventional Y-type molecular sieves with a reduced sodium oxide content are calcined for 4.5-7 hours at a temperature of 350-480° C. in an atmosphere containing 30-90% by volume of water vapor, and dried, Obtaining a Y-type molecular sieve with a reduced unit cell constant whose wat...

Embodiment 1

[0059] Get 2000 grams of NaY molecular sieves (on a dry basis) and add to 20 liters of decationized aqueous solution and stir to make it evenly mixed, and add 345ml of Ca(NO 3 ) 2 solution (concentration of the solution in terms of CaO is 248g / L), then add 300ml of RE (NO 3 ) 3 Solution (rare earth solution concentration is RE 2 o 3 Calculated as 319g / L), stirred, heated up to 90-95°C and kept for 1 hour, then filtered, washed, and the filter cake was dried at 120°C to obtain a unit cell constant of 2.471nm, a sodium oxide content of 6.6% by weight, and calcium oxide based on CaO. Content 4.9% by weight, RE 2 o 3 A Y-type molecular sieve with a total rare earth content of 4.4% by weight is then roasted for 6 hours at a temperature of 390° C. in an atmosphere containing 50 volume percent water vapor and 50 volume percent air to obtain a Y-type molecular sieve with a unit cell constant of 2.455 nm. After that, carry out Drying process, so that its water content is less tha...

Embodiment 2

[0063] Get 2000 grams of NaY molecular sieves (on a dry basis) and add them to 25 liters of decationized aqueous solution and stir to make them evenly mixed. Add 368ml of CaCl 2 solution (concentration of solution in terms of CaO: 248g / L), 400ml of RECl 3 solution (in RE 2 o 3 The calculated solution concentration is: 319g / L), stirring, heating up to 90-95°C for 1 hour, then filtering, washing, and drying the filter cake at 120°C to obtain a unit cell constant of 2.471nm and a sodium oxide content of 5.2% by weight , Calcium content in terms of CaO is 8.7% by weight, in terms of RE 2 o 3 A Y-type molecular sieve with a total rare earth content of 5.7% by weight is then calcined at a temperature of 450°C and 80% water vapor for 5.5 hours to obtain a Y-type molecular sieve with a unit cell constant of 2.461nm, and then dried to reduce its water content at 1 wt%, then follow SiCl 4 : Y-type zeolite = 0.6:1 weight ratio, feed SiCl vaporized by heating 4 The gas was reacted f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com