Preparation of catalyst catalyzing diesel hydro-conversion, and hydrogenation process

A technology for catalyzing diesel oil and hydroconversion, applied in hydrotreating process, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems of lowering product octane number, increasing gasoline product hydrogenation saturation, poor catalyst stability, etc. Achieve the effect of inhibiting excessive cracking, increasing hydrogen saturation, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

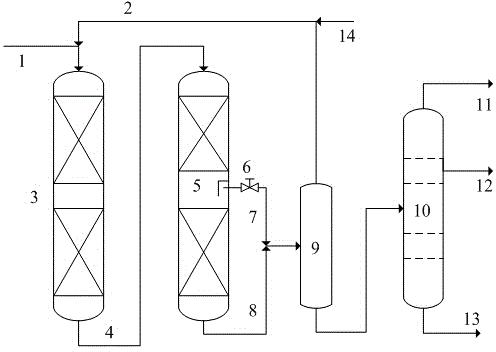

Method used

Image

Examples

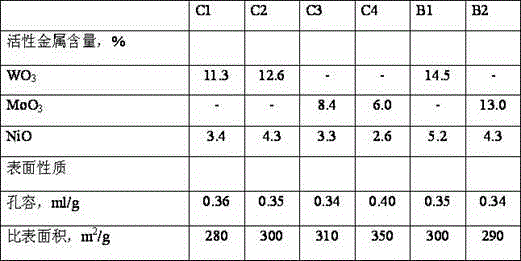

Embodiment 1

[0039] (1) Configure the W-Ni impregnation solution, first add ammonium metatungstate and nickel nitrate to distilled water to prepare a mixed solution of ammonium metatungstate and nickel nitrate, and adjust the tungsten oxide content in the mixed solution to 40g / 100ml, nickel oxide 12g / 100ml. Then in the mixed solution, dropwise adding a concentration of 25% ammonia solution to pH is 5.0;

[0040] (2) The W-Ni impregnating solution obtained in step (1) was impregnated with Y molecular sieve for 2 hours according to the liquid / solid mass ratio of 3:1, and then, after filtration, roasted at 120°C for 4 hours;

[0041] (3) Mix 100g of Y molecular sieve obtained in step (2) with 100g of macroporous alumina, add 4g / 100ml of dilute nitric acid, mix and roll in a mixer until it can be extruded, and extrude on an extruder to obtain the example 1 Catalyst C1.

Embodiment 2

[0043] (1) Configure the W-Ni impregnation solution, first add ammonium metatungstate and nickel nitrate to distilled water to prepare a mixed solution of ammonium metatungstate and nickel nitrate, and adjust the tungsten oxide content in the mixed solution to 30g / 100ml, nickel oxide 10g / 100ml. Then in the mixed solution, dropwise adding concentration is 2% potassium hydroxide solution to PH to be 5.5;

[0044] (2) The W-Ni impregnating solution obtained in step (1) was impregnated with Y molecular sieve for 2 hours according to the liquid / solid mass ratio of 3:1, and then, after filtration, roasted at 120°C for 4 hours;

[0045] (3) Mix 100g of Y molecular sieve obtained in step (2) and 50g of macroporous alumina, add 4g / 100ml of dilute nitric acid, mix and roll in a mixer until it can be extruded, and extrude on an extruder to obtain the example 2 Catalyst C2.

Embodiment 3

[0047] (1) To configure the Mo-Ni impregnation solution, first add molybdenum oxide and alkali nickel carbonate to distilled water to prepare a mixed solution. The mixed solution contains 20g / 100ml of molybdenum oxide and 7g / 100ml of nickel oxide based on the oxide of the metal salt. . Then in the mixed solution, dropwise adding a concentration of 2% potassium hydroxide solution to a pH of 6.0;

[0048] (2) The Mo-Ni impregnating solution obtained in step (1) was impregnated with Y molecular sieve for 2 hours according to the liquid / solid mass ratio of 3:1, and then, after filtration, roasted at 120°C for 4 hours;

[0049] (3) Mix 100g of Y molecular sieve obtained in step (2), 100g of silicon aluminum, 10g of nickel nitrate and 5g of molybdenum oxide, add 4g / 100ml of dilute nitric acid, mix and roll in a mixer until it can be extruded, and put it on the extruder The catalyst C3 of Example 3 was obtained by extruding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| dry point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com