Catalyst for fatty monoolefin hydrogenation saturation, and its preparing method and use

A catalyst and monoolefin technology, applied in the direction of addition of unsaturated hydrocarbons to hydrocarbon production, can solve problems such as poor catalyst strength, and achieve the effect of low octane number reduction rate and less side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

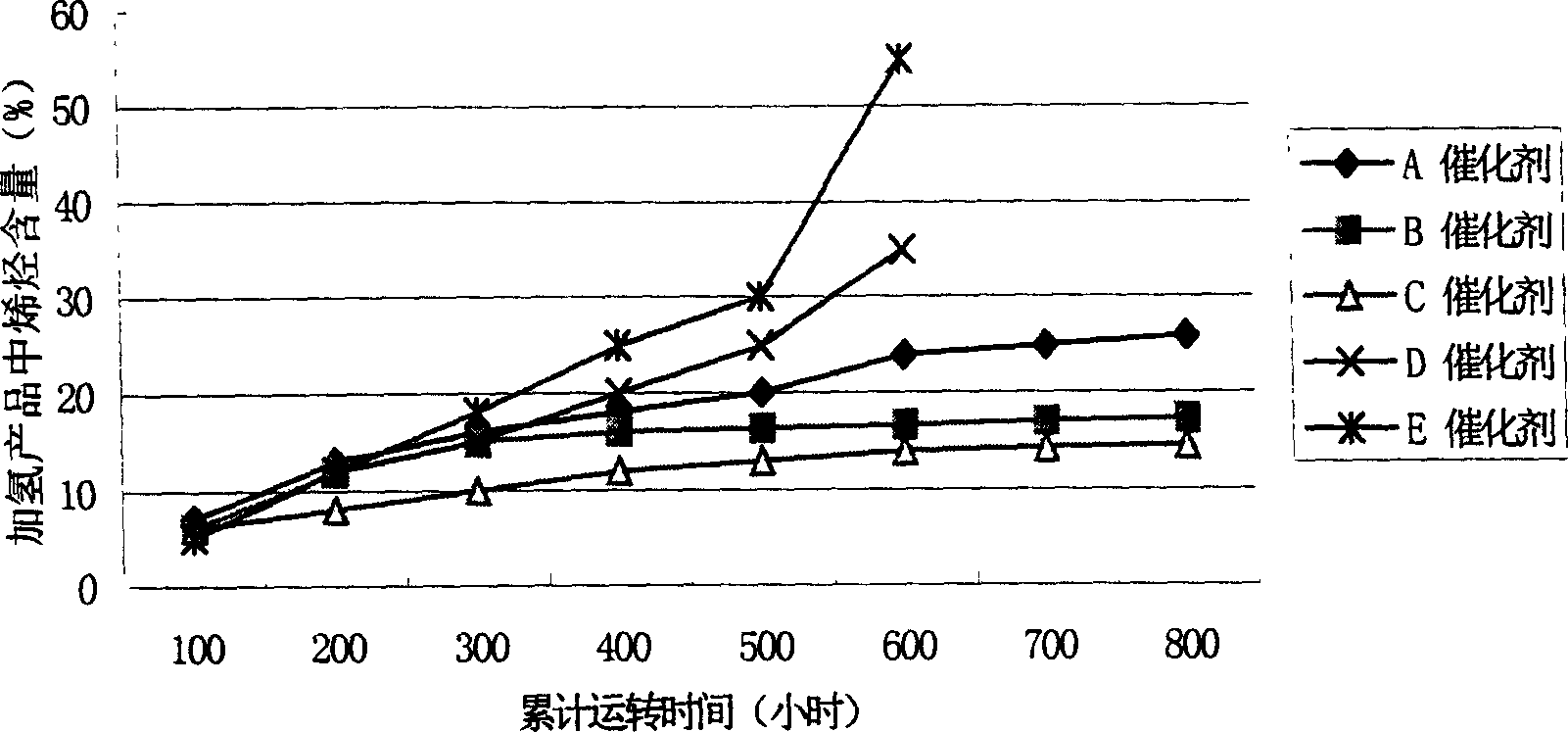

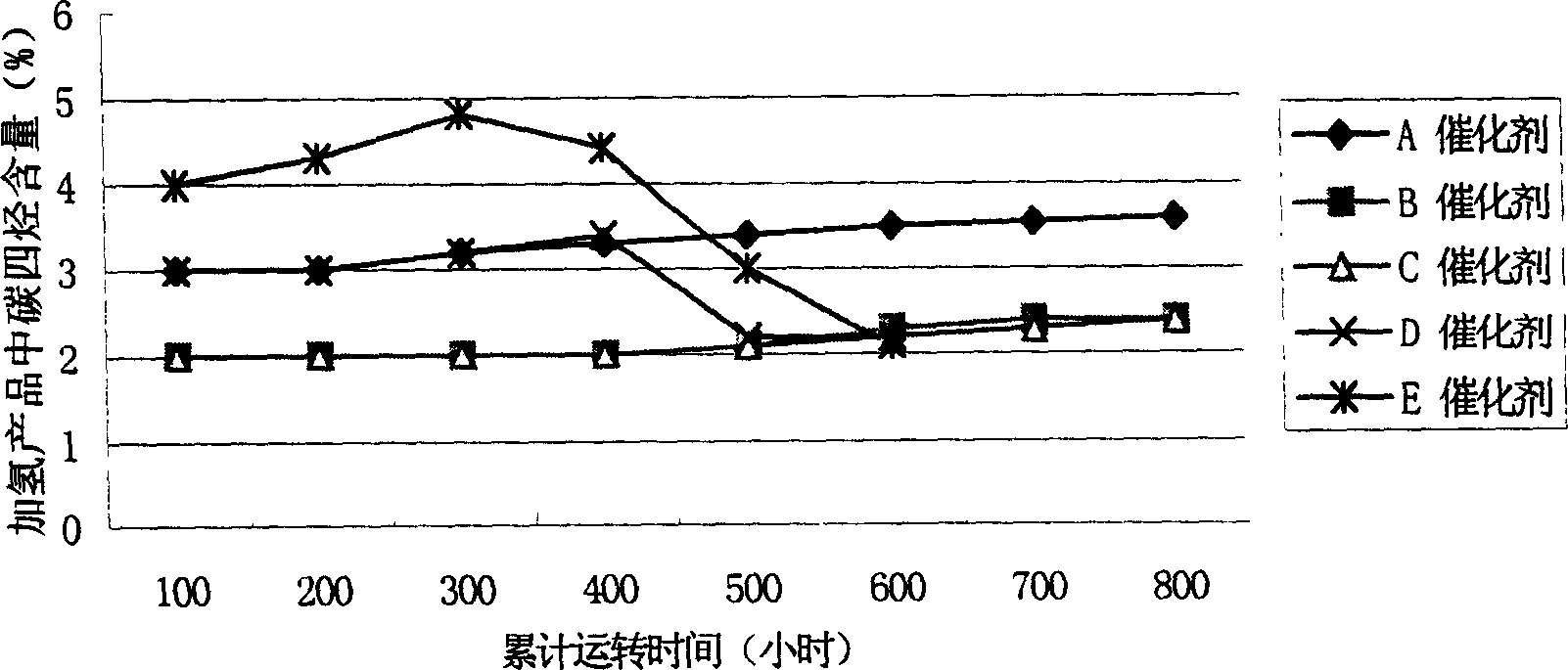

Examples

Embodiment 1

[0020] Take 3.0g of strontium carbonate and add appropriate amount of water, add citric acid to dissolve, impregnate on 100g of alumina carrier containing 2.0% of silicon dioxide, age for more than 2 hours, dry, and roast at 350°C for 4 hours to obtain the carrier.

[0021] Add 14.5g of molybdenum trioxide and 4.3mL of phosphoric acid into an appropriate amount of water, heat to boil, then slowly add 8.2g of nickel carbonate and 10.5g of nickel nitrate, dissolve and impregnate on 100g of alumina carrier, age for more than 8 hours, and dry , Calcined at 450°C for 4 hours to obtain the finished catalyst A.

Embodiment 2

[0023] Take 3.0g of strontium carbonate and add appropriate amount of water, add citric acid to dissolve, impregnate on 100g of alumina carrier, age for more than 2 hours, dry, and roast at 450°C for 4 hours to obtain the carrier.

[0024] Add 20.5g of ammonium molybdate and 4.3mL of phosphoric acid into an appropriate amount of water, heat to boil, then slowly add 26.5g of nickel nitrate, 2.7g of potassium carbonate, and then add 6.2ml of nitric acid, dissolve and impregnate on 100g of alumina carrier, and age More than 8 hours, drying, and roasting at 400° C. for 4 hours to obtain the finished catalyst B.

Embodiment 3

[0026] Take 11.0g lithium carbonate, add appropriate amount of water, add citric acid to dissolve, impregnate 100g alumina carrier, age for more than 2 hours, dry, and roast at 500°C for 4 hours to obtain the carrier.

[0027] Add 18.8g of molybdenum trioxide and 4.9mL of phosphoric acid into an appropriate amount of water, heat to boil, then slowly add 9.2g of nickel carbonate, 16.5g of nickel nitrate, 2.7g of potassium carbonate, dissolve, then add 3.0g of boric acid, dissolve and impregnate to 100g On the alumina carrier, aging for more than 8 hours, drying, and calcination at 500° C. for 4 hours, the finished catalyst C was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com