Graphene waterborne industrial coating and preparation method thereof

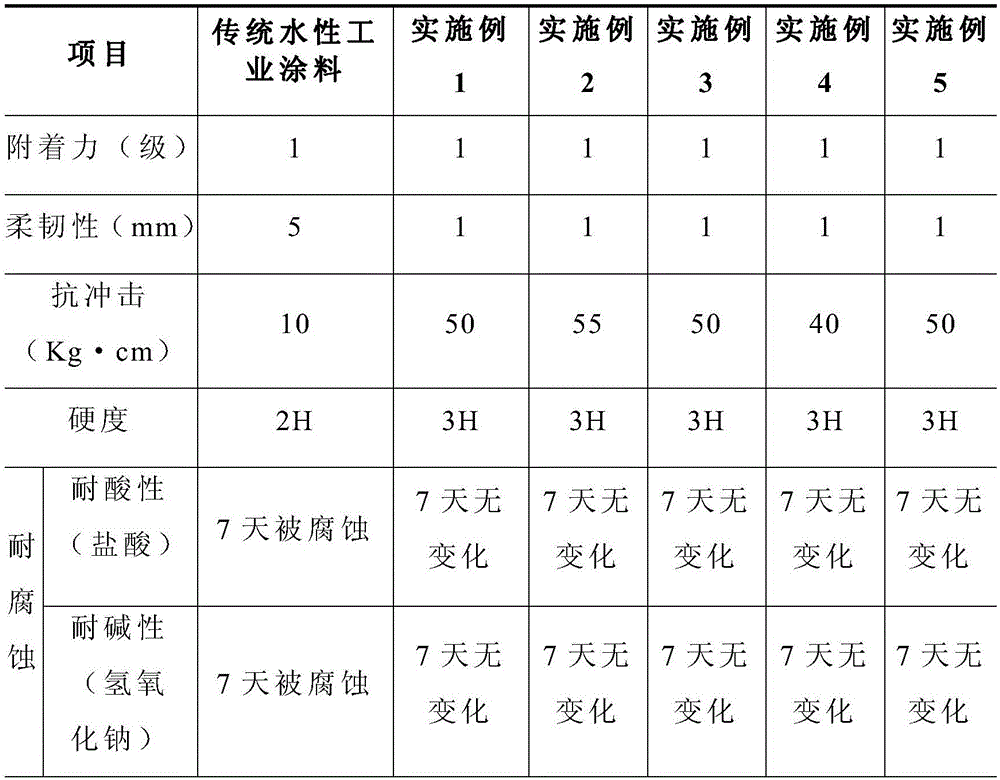

A kind of graphene water-based, industrial technology, applied in the field of graphene water-based industrial coatings and its preparation, can solve the problems such as chemical properties and flexibility are not well resolved, to improve chemical properties and flexibility, improve hardness and heat resistance , Improve the effect of wear resistance, heat resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1, the present embodiment provides a kind of graphene water-based industrial paint and preparation method thereof, comprises following material according to weight fraction in the paint: water-soluble oil-free alkyd resin (emulsion): 30 parts, graphene aqueous dispersion: 5 Parts (the mass ratio of graphene to water is 1:1000), AMP-95# (ammonia neutralizer): 0.2 parts, BYK-028 (defoamer): 0.25 parts, TEGO270 (wetting agent): 0.2 parts , EFKA3772 (leveling agent): 0.5 parts, color paste (70% white paste): 20 parts, HASE-5 (thickener): 1 part, water: 5 parts.

[0021] The preparation process is that the emulsion and graphene aqueous dispersion are added to the mixing tank and stirred at a stirring speed of 600 rpm for 30 minutes, and the mixture is obtained after the mixture is evenly mixed; then the defoaming agent and the wetting agent are sequentially added to the mixture , leveling agent, color paste, and then adjust the speed to 700 rpm, stirring for 40 mi...

Embodiment 2

[0022] Embodiment 2, the present embodiment provides a kind of graphene water-based industrial paint and preparation method thereof, comprises following material according to weight fraction in the paint: styrene-butadiene emulsion: 30 parts, graphene aqueous dispersion: 10 parts (the mixture of graphene and water The mass ratio is 1:100), AMP-95# (ammonia neutralizer): 1 part, DREWPLUSL-1311 (defoamer): 0.5 parts, diisooctyl hyaluronate (wetting agent): 0.5 parts, alkyl modified organosiloxane (leveling agent): 1 part, color paste (80% white paste): 10 parts, polyurethane thickener (thickener): 5 parts, water: 30 parts.

[0023] The preparation process is that the emulsion and graphene aqueous dispersion are added to the mixing tank and stirred at a stirring speed of 600 rpm for 30 minutes, and the mixture is obtained after the mixture is evenly mixed; then the defoaming agent and the wetting agent are sequentially added to the mixture , leveling agent, color paste, and then ...

Embodiment 3

[0024] Embodiment 3, the present embodiment provides a kind of graphene water-based industrial paint and preparation method thereof, comprises following material according to weight fraction in the paint: water-based alkyd resin: 45 parts, graphene aqueous dispersion: 2 parts (graphene and water The mass ratio is 1:500), AMP-95# (ammonia neutralizer): 0.1 parts, DREWPLUSL-1311 (defoamer): 0.3 parts, alkyl aryl polyether (wetting agent): 0.8 parts, Fluorine-modified acrylate (leveling agent): 0.5 parts, color paste (80% white paste): 30 parts, associative alkali-swellable thickener (thickener): 3 parts, water: 20 parts.

[0025] The preparation process is that the emulsion and graphene aqueous dispersion are added to the mixing tank and stirred at a stirring speed of 650 rpm for 30 minutes, and the mixture is obtained after the mixture is uniformly mixed; then the defoamer and the wetting agent are added to the mixture in sequence , leveling agent, color paste, and then adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com