Patents

Literature

49results about How to "Breathable and comfortable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

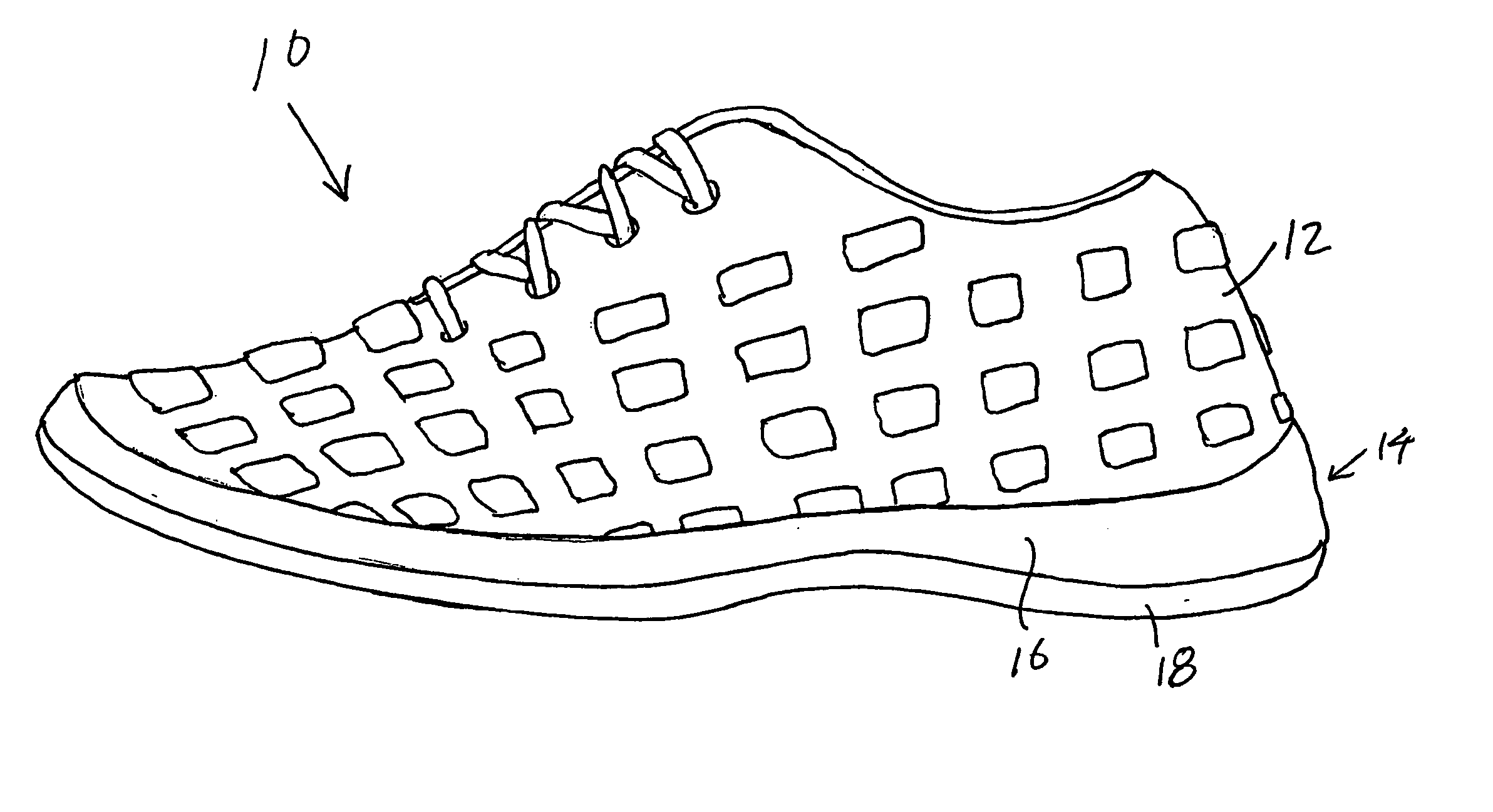

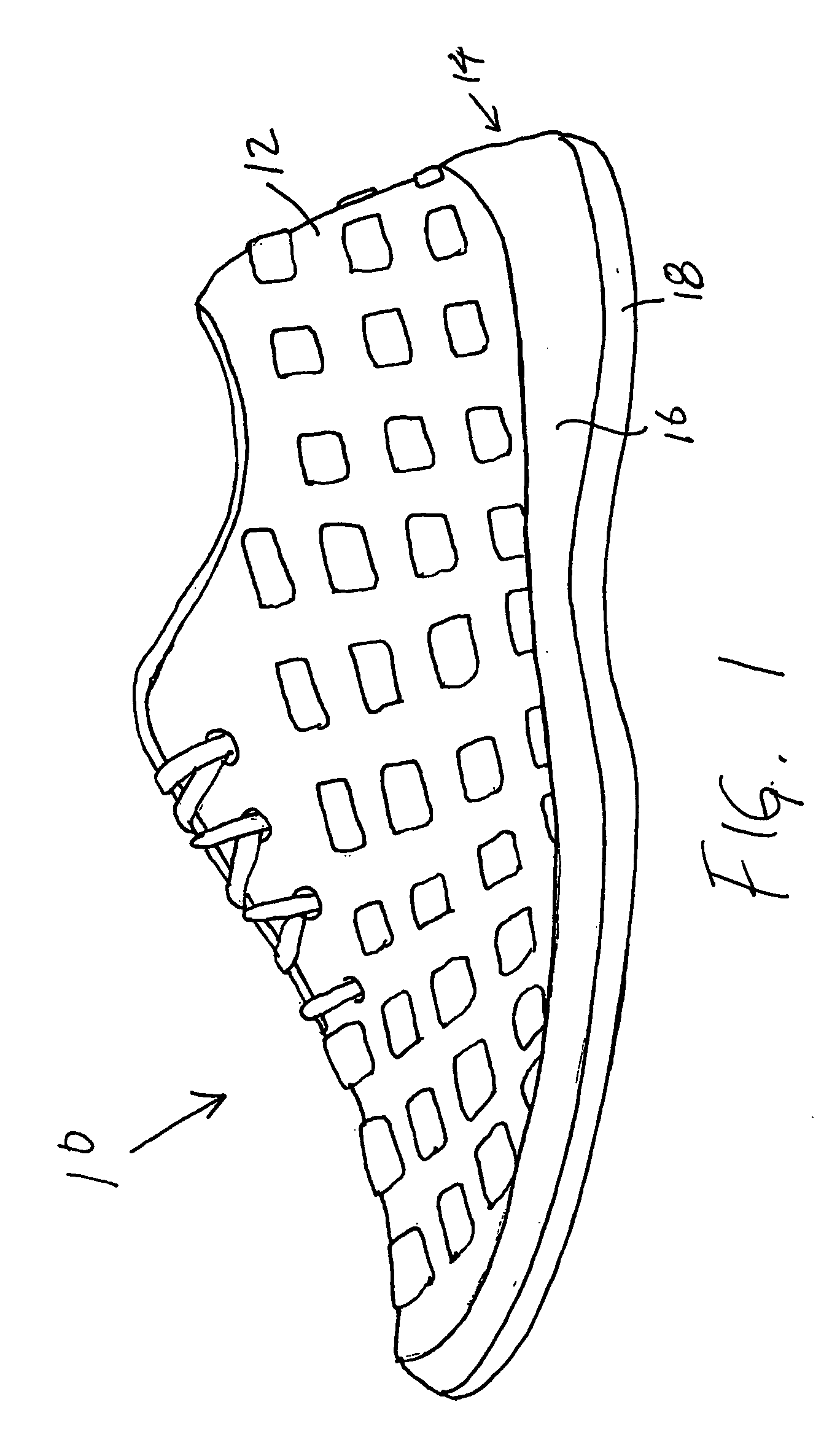

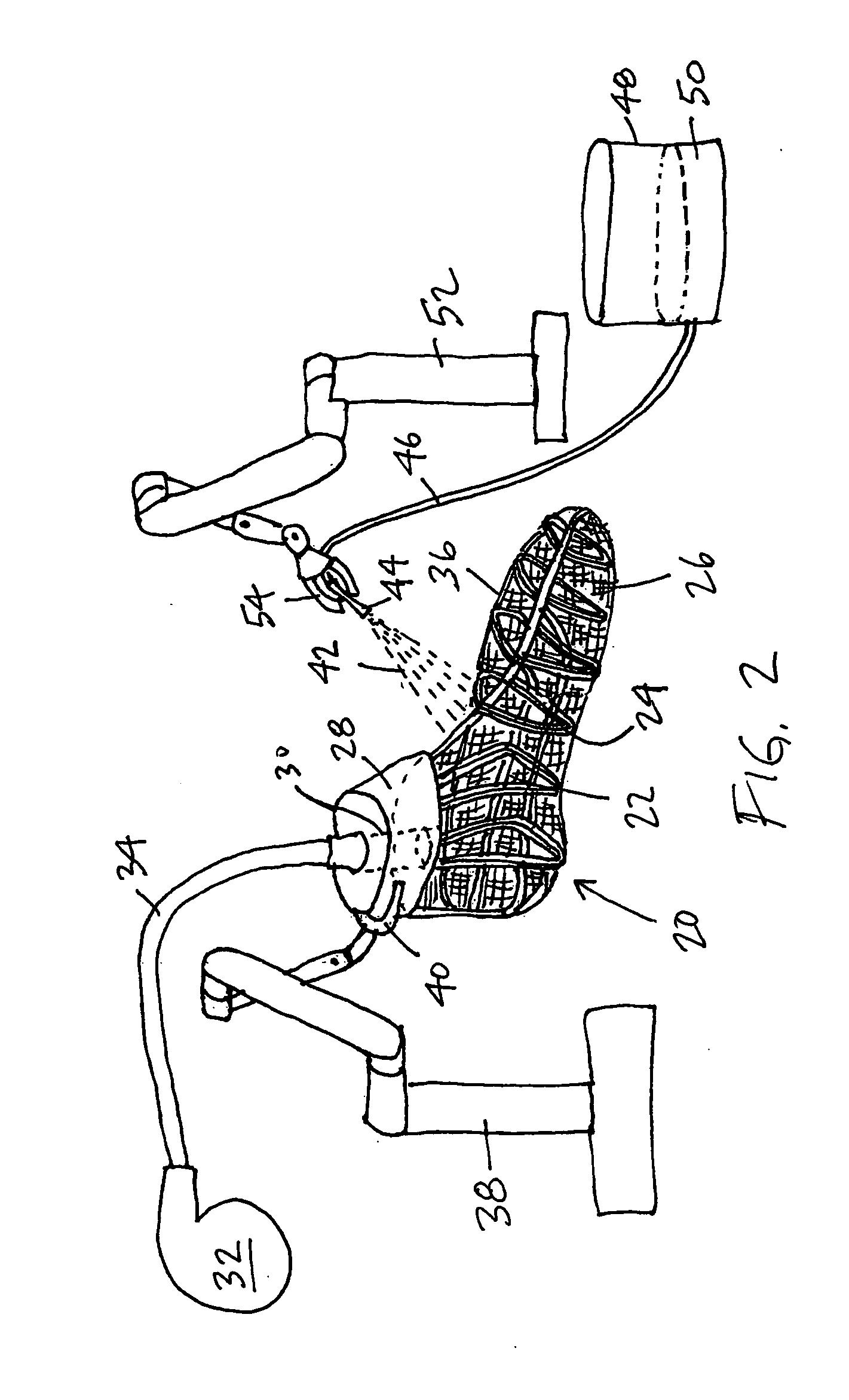

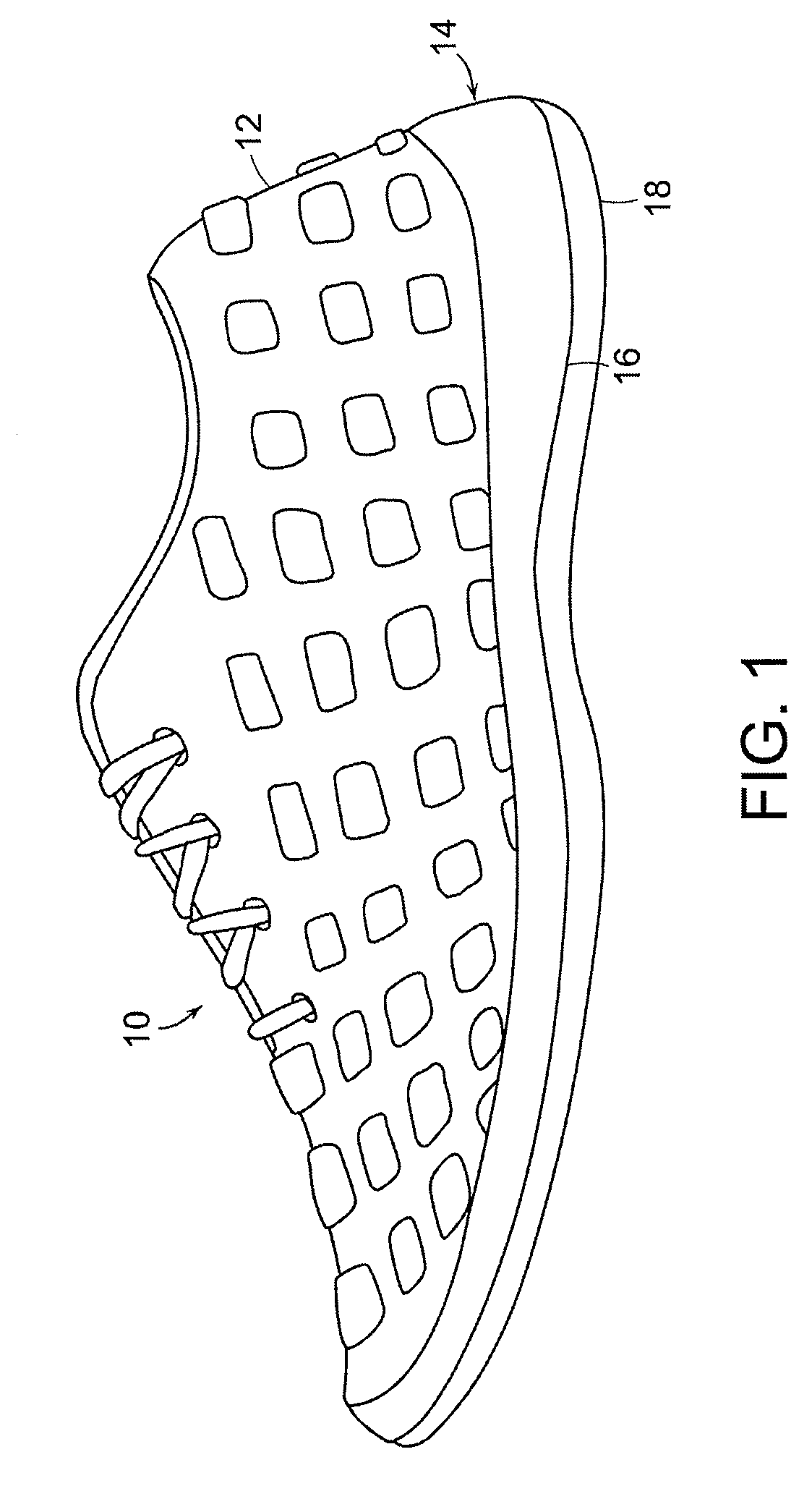

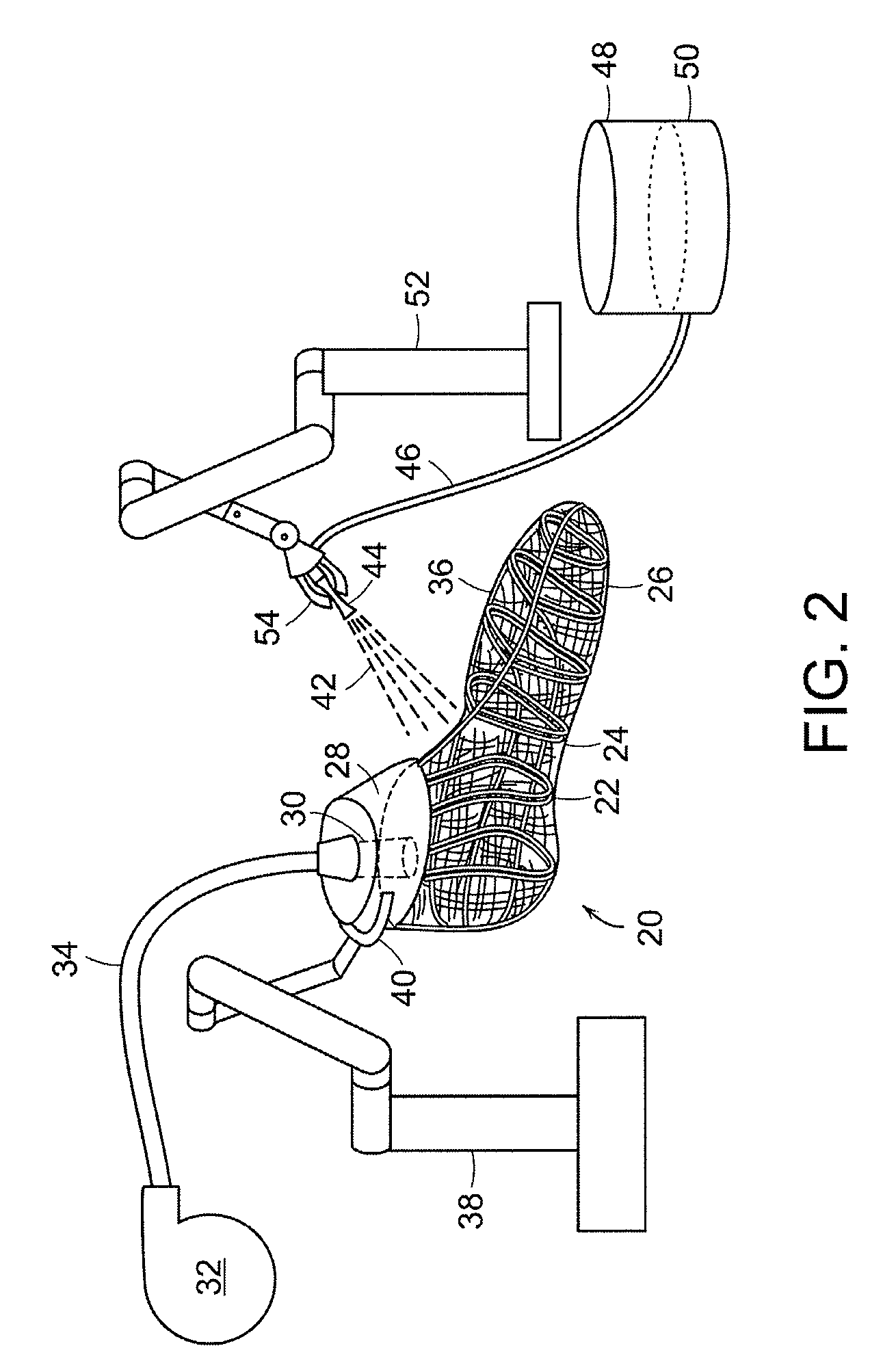

Article of footwear of nonwoven material and method of manufacturing same

InactiveUS20060276095A1Improved breathability and moldability and abrasion resistance and and recovery and water resistance and recyclabilityImprove breathabilityWood working apparatusCeramic shaping apparatusEngineeringFiber

A method of forming a portion of an article of footwear includes the steps of providing a last having an exterior surface, extruding a plurality of polymeric fibers, projecting a stream of the extruded polymeric fibers onto the last to form a mat having the shape of the exterior of the last, and subjecting the mat to heat and pressure in a mold.

Owner:NIKE INC

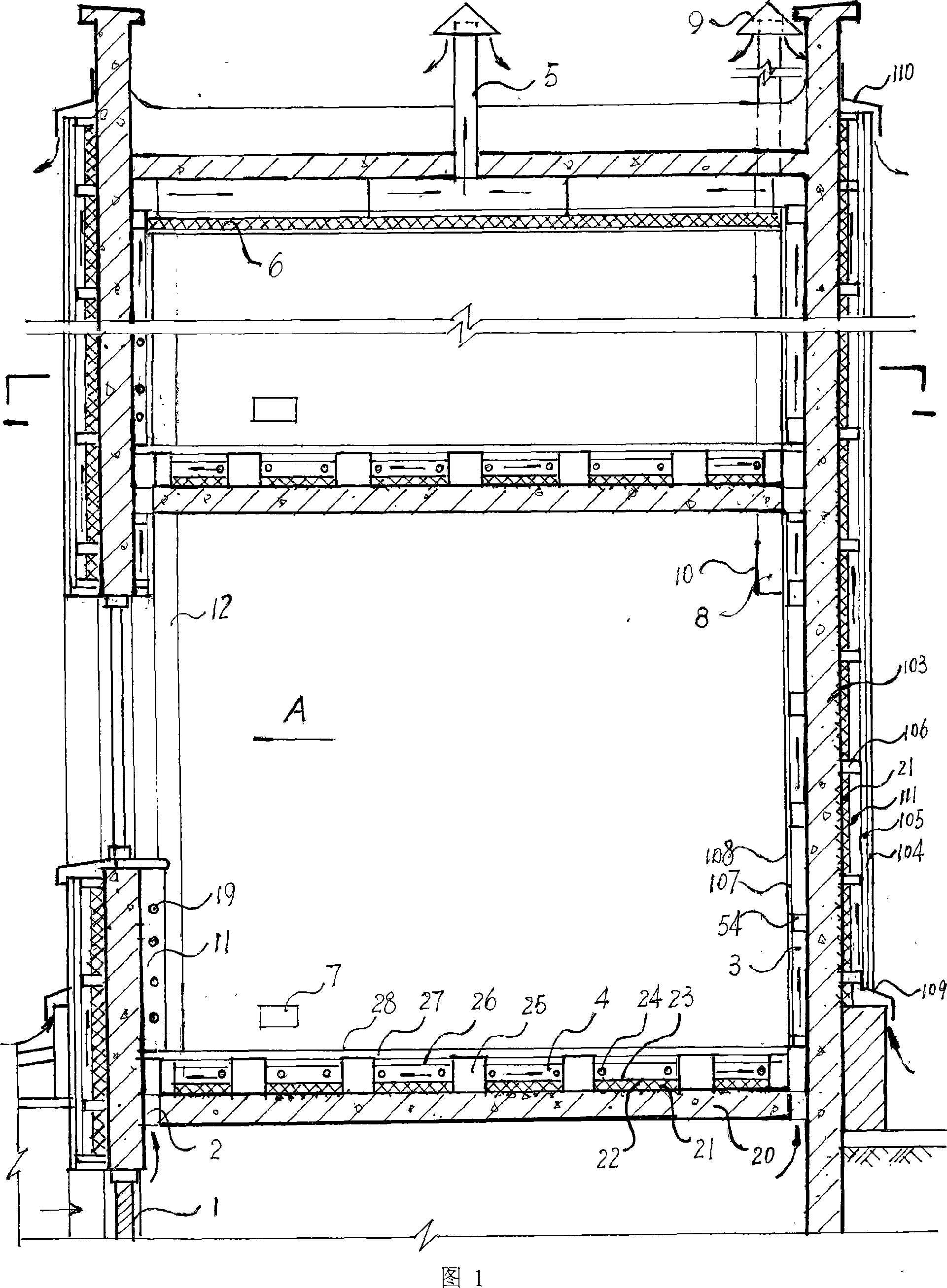

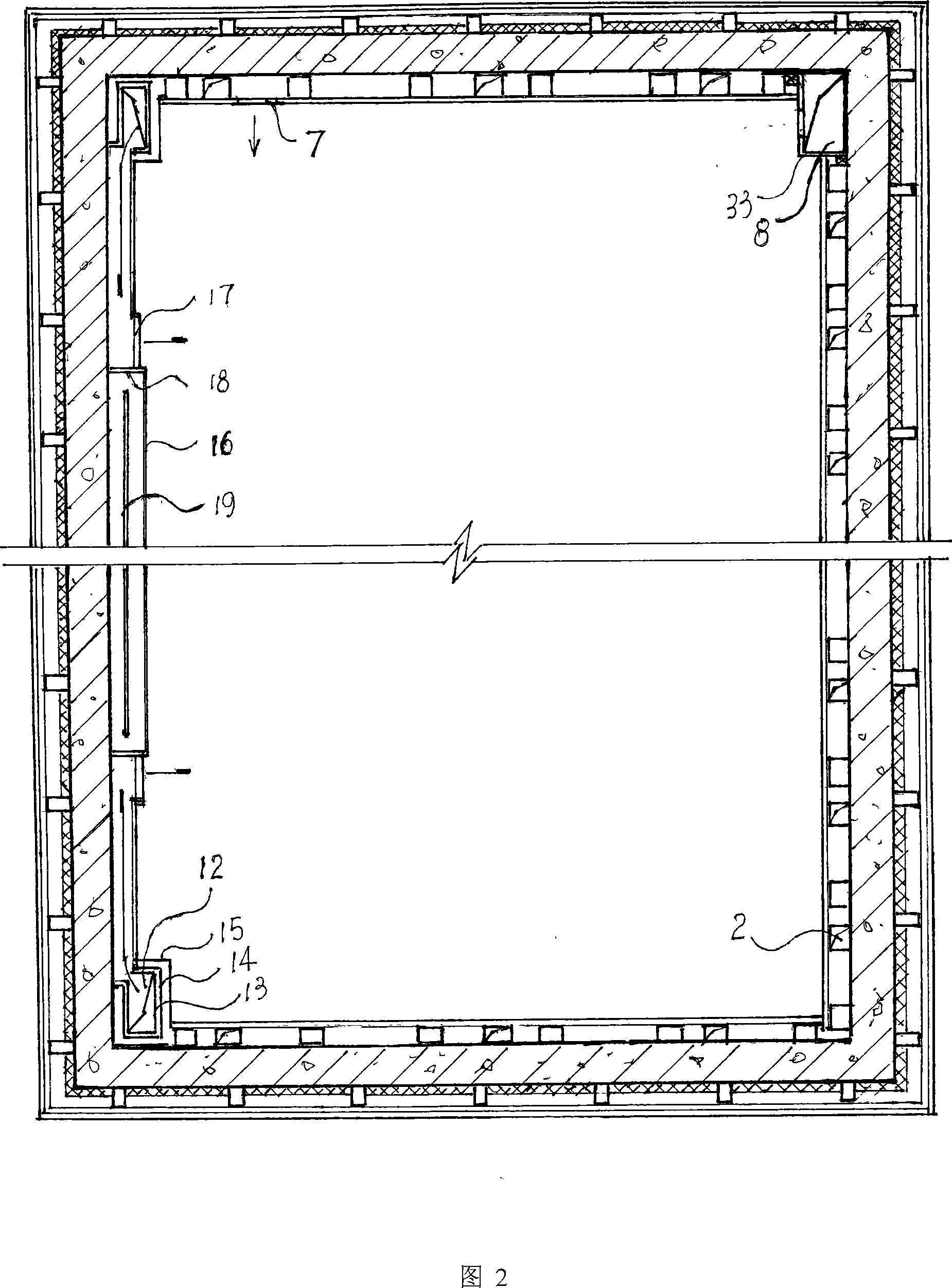

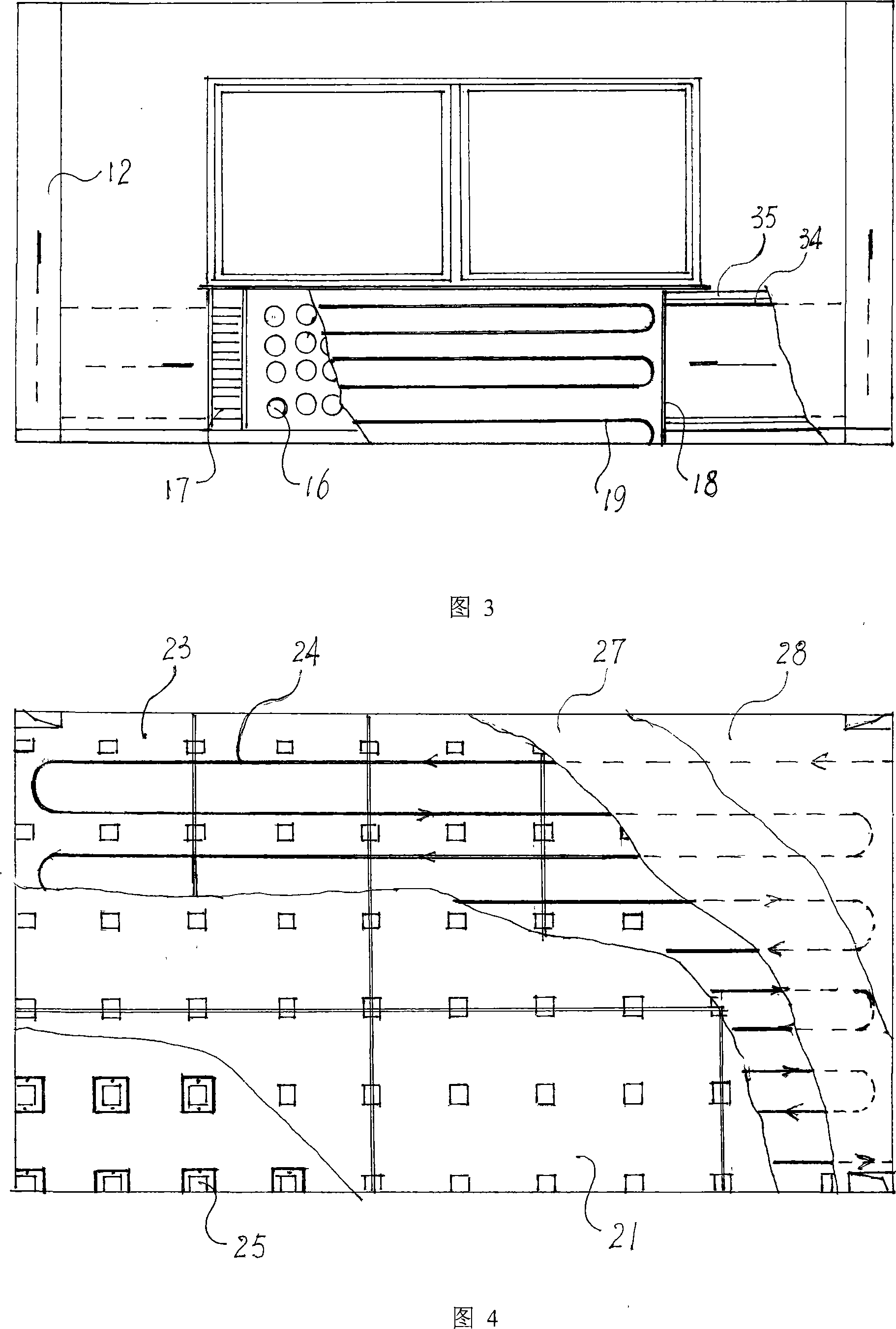

Environment-protection energy-saving ventilating air-conditioning sound-insulating novel building and construction method

InactiveCN101070713ATo achieve the purpose of auxiliary regulationReduce consumptionCovering/liningsLighting and heating apparatusNatural ventilationRoom temperature

The invention relates to a new construction and its methods for environmental protection, energy conservation, natural ventilation, air conditioning, noise insulation and heat preservation. It is applicable to all kinds of industrial and civil buildings. Its character is that it adopts the rationale of air-control to natural draft by cavities. In order to natrurally control the room-temperature and natural draft , it needs many cavities around the house to prepare for the natrural draft, soundproofing air-control circulate system work in the cavities formed by the intercommunication of the wall and ground ,using some special methods such as airy-control the ground and sound isolation control the wall by the wind cavities. Besides,it also recommends a manufactural erectional construction way which is suitable for the sustaining system between the earth-cavity and wall- cavity .The invention eliminates disadvantage of traditional out-of-date technique in resource-saving and environment protesting,with great worth of soundproofing, and improves noise insulation of buildings and natural ventilation permeability effect of environmental protection, energy saving and economy.

Owner:冯刚克

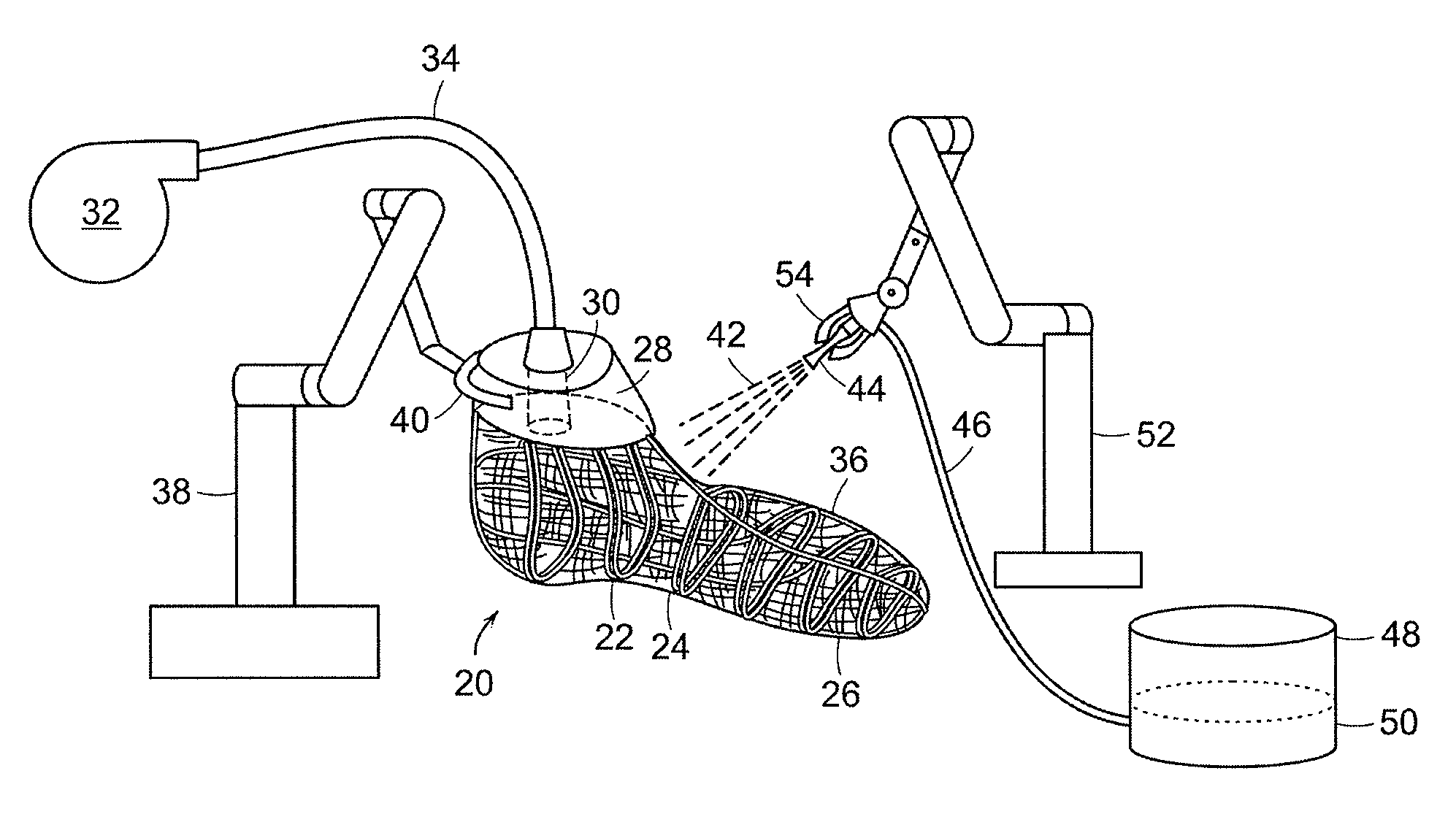

Article of Footwear of Nonwoven Material and Method of Manufacturing Same

InactiveUS20090140470A1Improve breathabilityGood moldabilityLaminationLamination apparatusFiberEngineering

A method of forming a portion of an article of footwear includes the steps of providing a last having an exterior surface, extruding a plurality of polymeric fibers, projecting a stream of the extruded polymeric fibers onto the last to form a mat having the shape of the exterior of the last, and subjecting the mat to heat and pressure in a mold.

Owner:NIKE INC

High-grade pure natural thermal underwear fabric

The invention discloses high-grade pure natural thermal underwear fabric, which is characterized in that: the fabric employs knitting technology and comprises face yarn and lining yarn, wherein the face yarn is soybean protein fiber blended yarn; the lining yarn is milk fiber blended yarn; the soybean protein fiber blended yarn and the milk fiber blended yarn take up 30%-55% and 45%-70% by weight percentage of the overall fabric respectively. In such a way, the high-grade pure natural thermal underwear fabric disclosed by the invention combines the properties of a plurality of blended fibers, has excellent skin-friendly property, is available for being worn inside, breathable and comfortable, excellent in thermal insulation performance, and good in elasticity.

Owner:SUZHOU CHUANGYU WEAVING

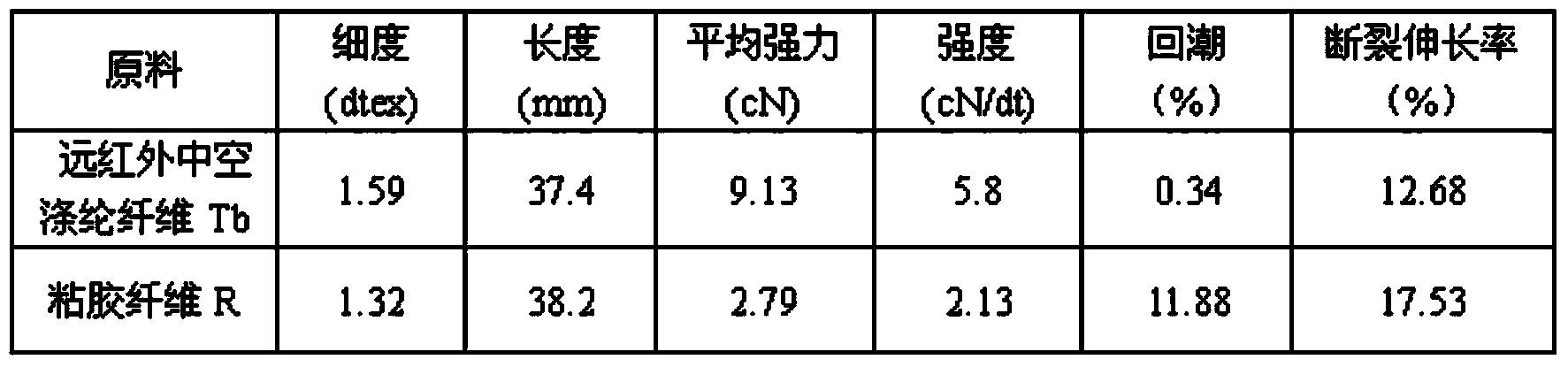

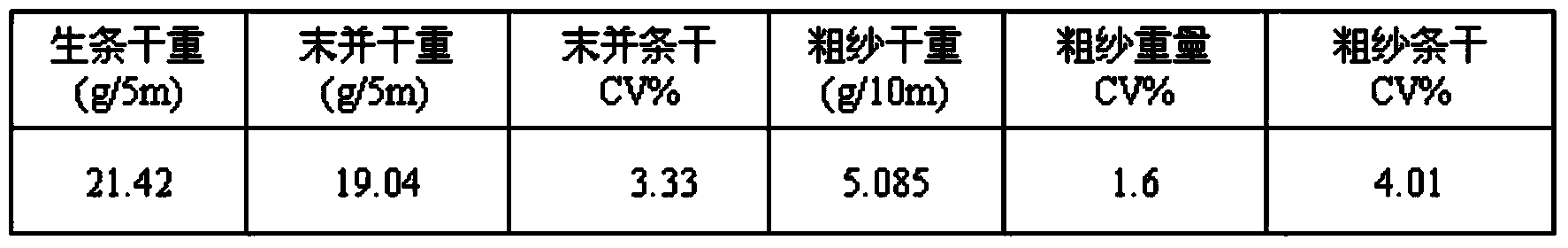

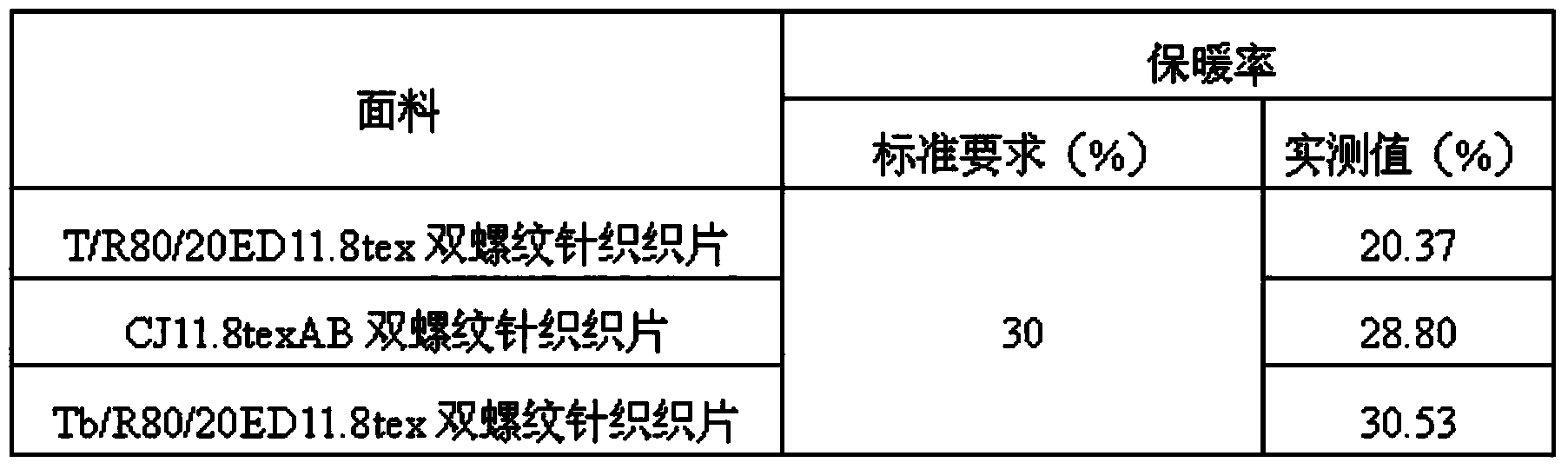

Far infrared hollow thermal yarns and processing method

The invention discloses far infrared hollow thermal yarns and a processing method. The far infrared hollow thermal yarns are processed by blending 75 to 85 weight percent of far infrared hollow polyester fibers and 15 to 25 weight percent of viscose fibers. The processing method comprises procedures of blowing, carding, drawing, roving, spinning and spooling. According to the far infrared hollow thermal yarns and the processing method, the problems of heaviness, poor air permeability, inconvenience for movement and lack of beauty of thermal garments in the prior art are effectively solved; a garment fabric woven from the yarns is high in thermal insulation property, light, air-permeable, comfortable and long in service life, and has high practical value.

Owner:浙江春江轻纺集团有限责任公司

Multifunctional antioxidant fabric

InactiveCN103485028AImprove antioxidant capacityWith radiation protectionWoven fabricsYarnPolyamideViscose

The invention discloses a multifunctional antioxidant fabric. The multifunctional antioxidant fabric is knitted by wefts and warps. The warps are knitted by blending silver fibers and Dacron fibers, and the wefts are knitted by blending viscose and polyamide fabric mixed with silver ions. The fabric is knitted by blending the silver fibers and the Dacron fibers and blending the viscose and the polyamide fabric mixed with the silver ions in a weft and warp manner, so that the fabric has the advantages of good antioxidant performance, stable radiation proofing and shielding properties, bacteriostasis and easy maintenance, permeability and comfortability.

Owner:WUJIANG HAIFENG WEAVING

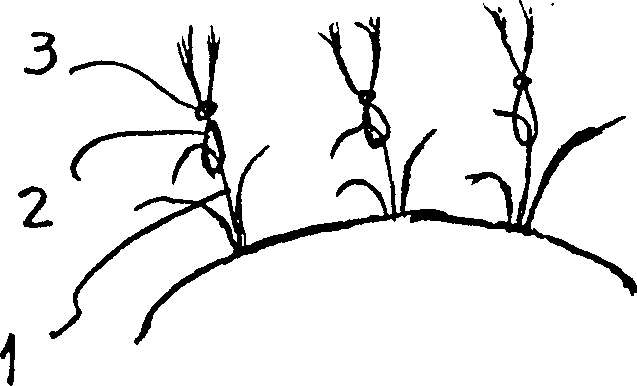

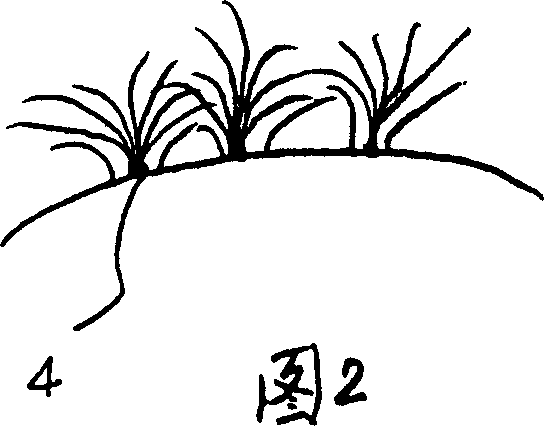

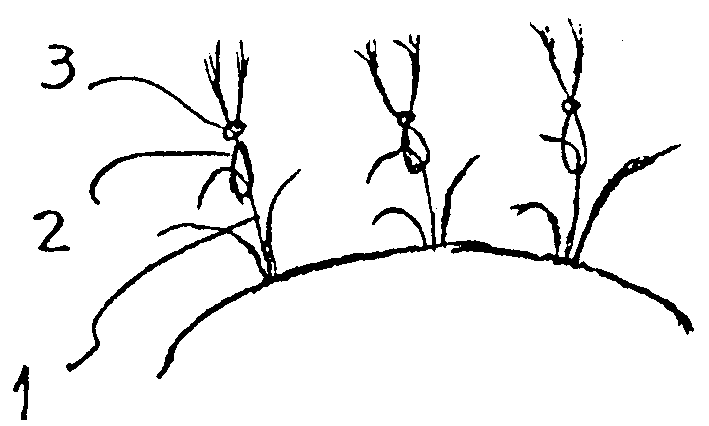

Method for implant hairs

A method for transplanting true hair on head skin of alopecia patient includes such steps as defatting one or more true hairs, disinfecting, coloring, curling, folding by one half, passing in the hole of a small bead, passing one actual hair of the alopecia patient through the ring formed by the bent hairs, making a knot, fixing by non-toxic adhesive, removing small bead, and repeating said steps for other positions one by one. Its advantages are low cost, no damage and by-effect, high air permeability, and lifelike appearance.

Owner:朱惠芳

Production process of nylon cotton bound cloth fabric

InactiveCN103469631ABreathable and comfortableDry-cleaning apparatus for textilesDyeing processProcess engineeringDyeing

The invention discloses a production process of a nylon cotton bound cloth fabric. The production process specifically comprises the following steps of weaving, dyeing, washing, sheathing cotton, performing secondary washing and performing post-finishing and setting. The fabric produced by the production process disclosed by the invention has the characteristics of air permeability and comfort.

Owner:NANTONG SAIHUI TECH DEV

Anti-wrinkle high-elasticity blend fiber

The invention discloses an anti-wrinkle high-elasticity blend fiber, which is blended and woven by the following components in percentage by weight: 35%-44% of a rabbit-hair protein transgenic fiber, 26%-28% of a corn fiber, 18%-20% of a soybean protein fiber, 8%-10% of a silkworm protein fiber and 4%-7% of a pineapple leaf fiber. The anti-wrinkle high-elasticity blend fiber is blended and woven by a plurality of fibers, so that the anti-wrinkle high-elasticity blend fiber has the characteristics of being high in tensile strength, not easy to drape, long in service cycle, breathable and comfortable.

Owner:太仓市雄瑞化纺有限公司

Composite fabric manufacturing process capable of preventing antibacterial effective substances from being lost

InactiveCN107571555AGuaranteed level dyeingGuaranteed uptake rateSynthetic resin layered productsDyeing processCardingFilamentation

The invention discloses a composite fabric manufacturing process capable of preventing antibacterial effective substances from being lost. The composite fabric manufacturing process comprises the following steps: selecting bamboo raw materials which are processed by bamboos of the current year, classifying and respectively cutting off the bamboo raw materials, putting bamboo slices into boiled water for scouring for primary softening, taking out the scoured bamboo slices after the process is completed, cleaning the bamboo slices with water, putting the bamboo slices into a soaking solution, processing the bamboo slices with machinery, separating coarse fibers through a filamentation machine, flushing the fibers with water for degumming, putting the bamboo fibers into a cooking boiler for secondary softening, cleaning the bamboo fibers subjected to the zymolysis, and carrying out bleaching, oiling, softening, opening and carding, thus obtaining raw bamboo fibers for spinning. The composite fabric manufacturing process keeps the strength of a fabric, guarantees the dye uptake of the fabric, reduces the shrinkage rate of the fabric improves the handfeel of the fabric, enhances the temperature resistance and the adsorption strength of the bamboo fibers, and achieves no-losing effect; the characteristic of high-temperature resistance of the bamboo fibers is improved, so that influence of the temperature on the fabric is low.

Owner:ZHEJIANG EMF COSPLAY CULTURE IND

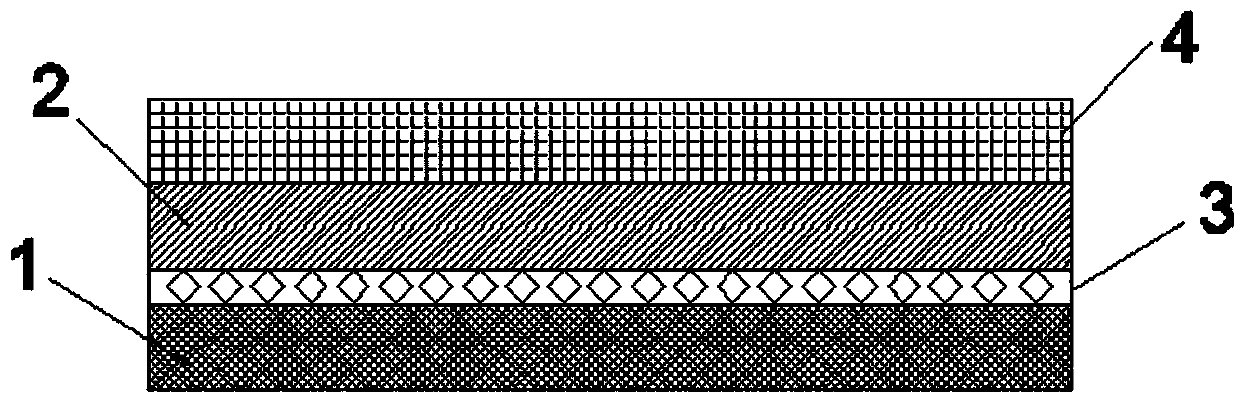

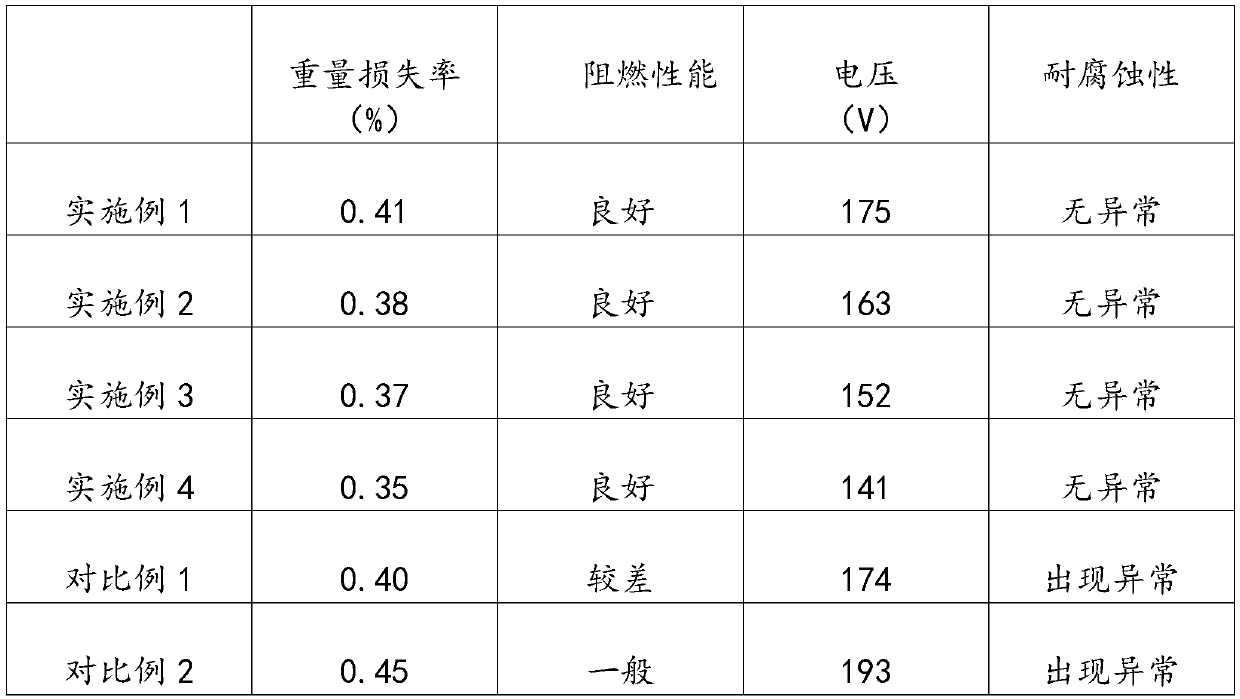

Anti-static flame-retardant composite fabric and preparation method thereof

ActiveCN109572092AImprove breathabilityBreathable and comfortableSynthetic resin layered productsCoatingsFiberAdhesive

The invention discloses anti-static flame-retardant composite fabric and a preparation method thereof. The anti-static flame-retardant composite fabric comprises a first fabric layer, a second fabriclayer, an electric conducting layer and a flame-retardant layer. The second fabric layer is positioned above the first fabric layer. The first fabric layer and the second fabric layer adopt comfortable ventilating fabric. The electric conducting layer is between the first fabric layer and the second fabric layer. The flame-retardant layer is positioned on an outermost layer of the fabric, and theouter surface of the second fabric layer is coated by the flame-retardant layer. The preparation method is capable of, through blending natural silks and ice silks, forming the first fabric layer andthe second fabric layer, wherein the fabric is soft in texture and has good air permeability; through alternately spinning graphite fibers and acetate fibers, forming a fiber net, and forming the electric conducting layer to connect the first fabric layer and the second fabric layer, wherein the air permeability of the fabric is guaranteed, and the fabric has excellent electrical conductivity; andthrough an adhesive, coating on the second fabric layer by flame-retardant paint so as to form the flame-retardant layer, thereby forming the anti-static, flame-retardant, ventilating and comfortablefabric.

Owner:安徽劲派新材料科技有限公司

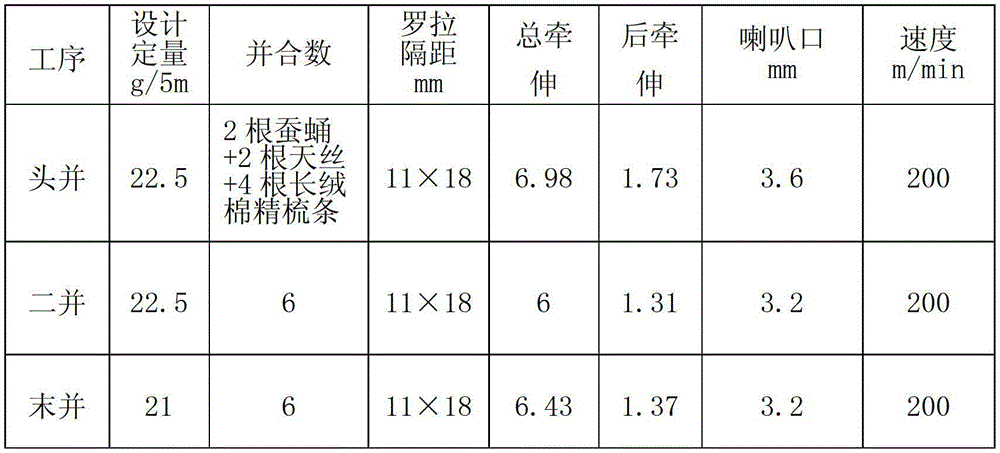

Method for producing high-grade knitting yarns by blending of silkworm chrysalis protein fibers, bamboo fibers and cotton

The invention relates to a method for producing high-grade knitting yarns by blending of silkworm chrysalis protein fibers, bamboo fibers and cotton. After being processed by blowing, carding and pre-drawing, silkworm chrysalis protein fibers are in drawing with bamboo pre-drawing slivers and combed cotton slivers during the breaker drawing, and then are subjected to secondary drawing, roving, spinning and spooling, so that bobbins are produced. Fibers are wetted and oiled before being blown, so that flying and adhering caused by static electricity are reduced. Damages to the fibers during carding are reduced and the fibers are transferred smoothly. Since drawing delivery speed is reduced, and smoothness of bell-mouths and coiler pipe chutes is guaranteed, drawing delivery is smooth. During roving, yarn evenness is improved, and accidental stretching in rove unwinding is reduced. Yarn hairness is reduced, napping and piling resistance performance is good, and the clothes made of the yarns are light as silk, are elegant, soft, fine, smooth, breathable, skin friendly, environment friendly, bright in color, have breaking strength higher than that of silk fabrics of the same-type tissue structure, and have draping, wear resistance, bending stiffness and the like similar to those of the like silk fabrics.

Owner:JIHUA 3509 TEXTILE

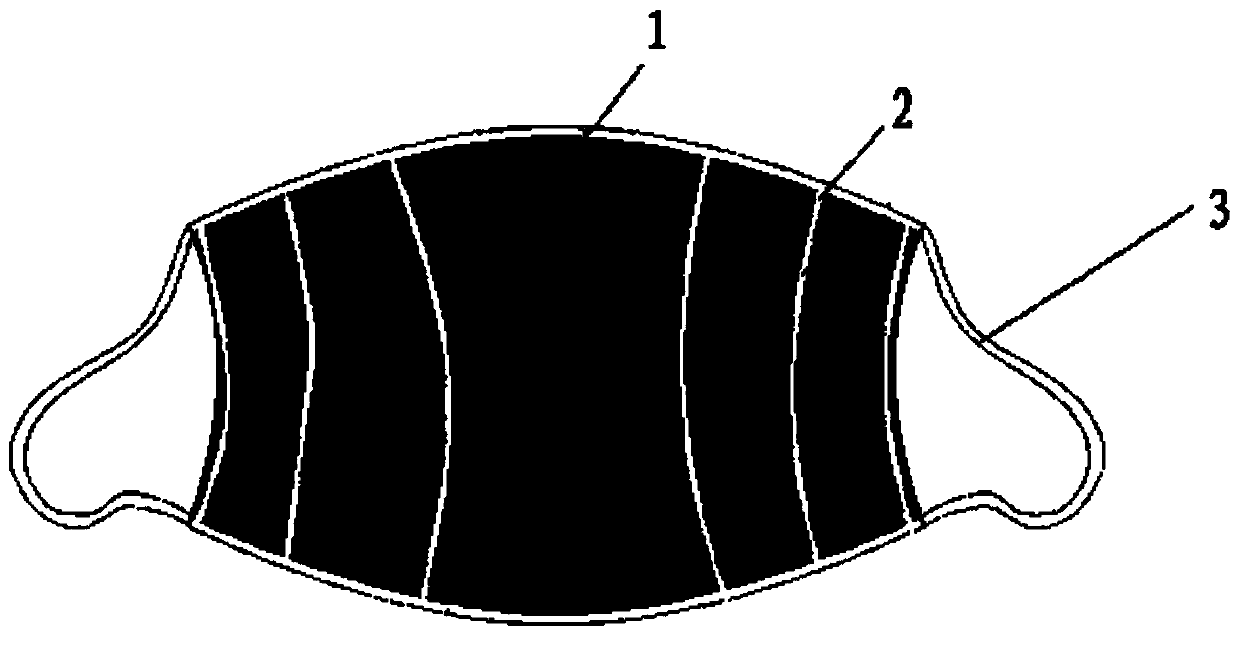

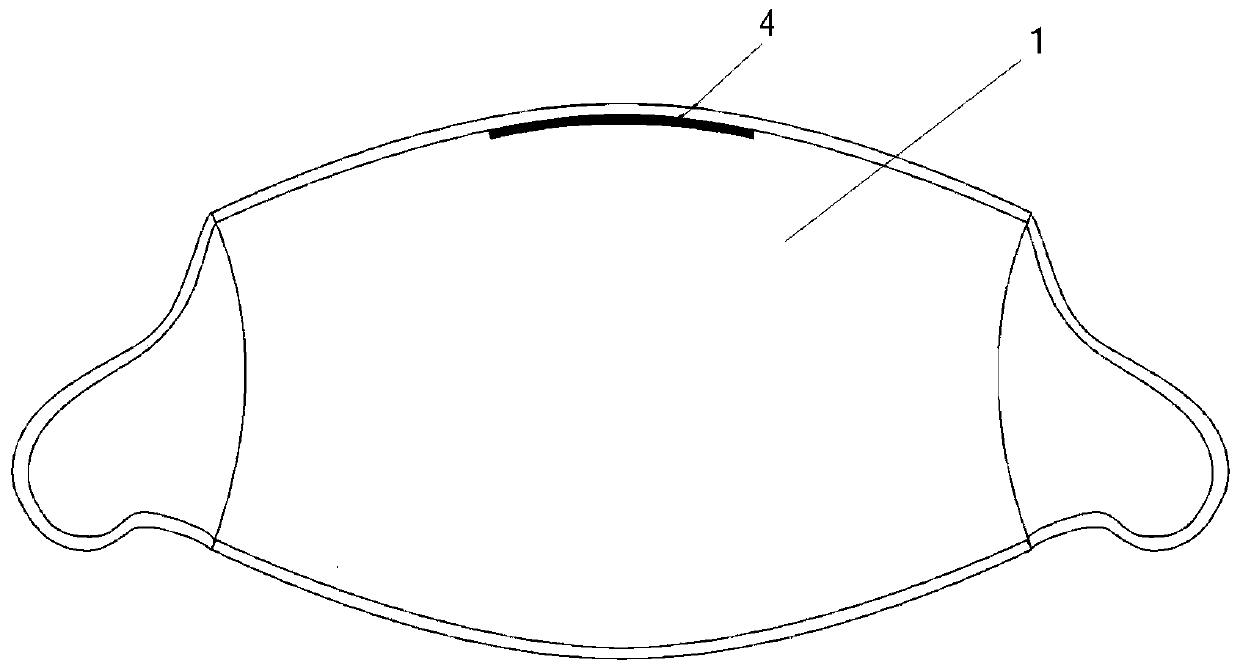

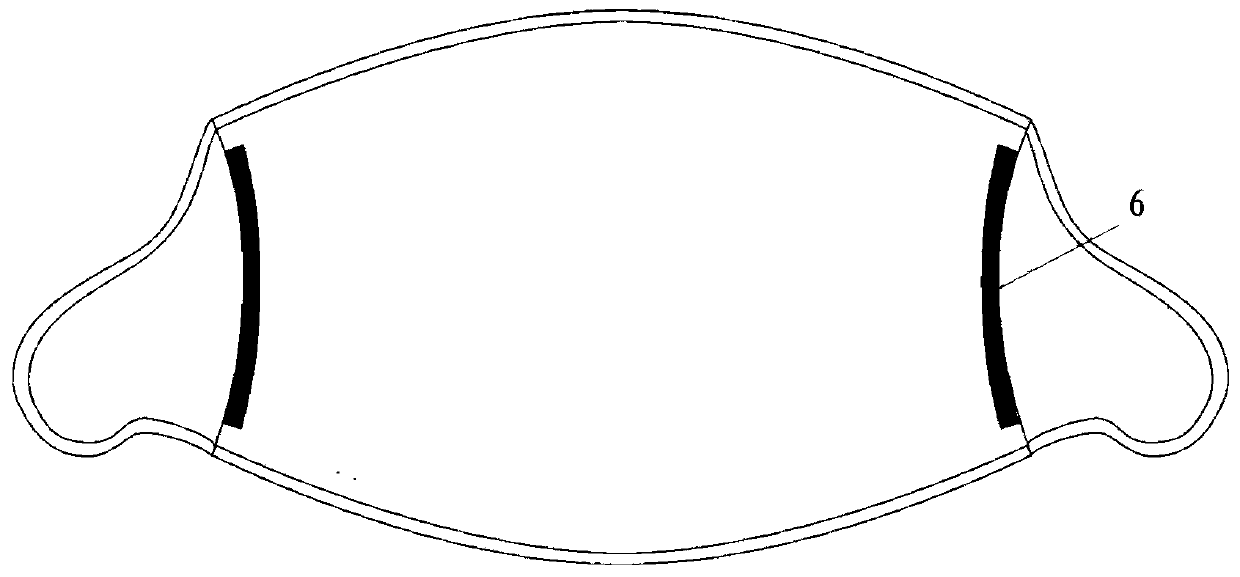

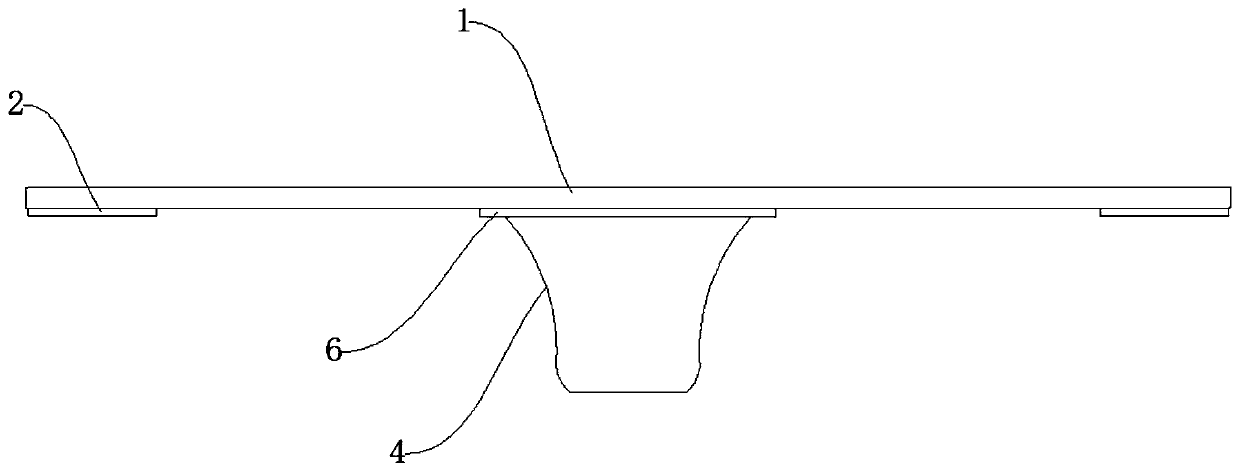

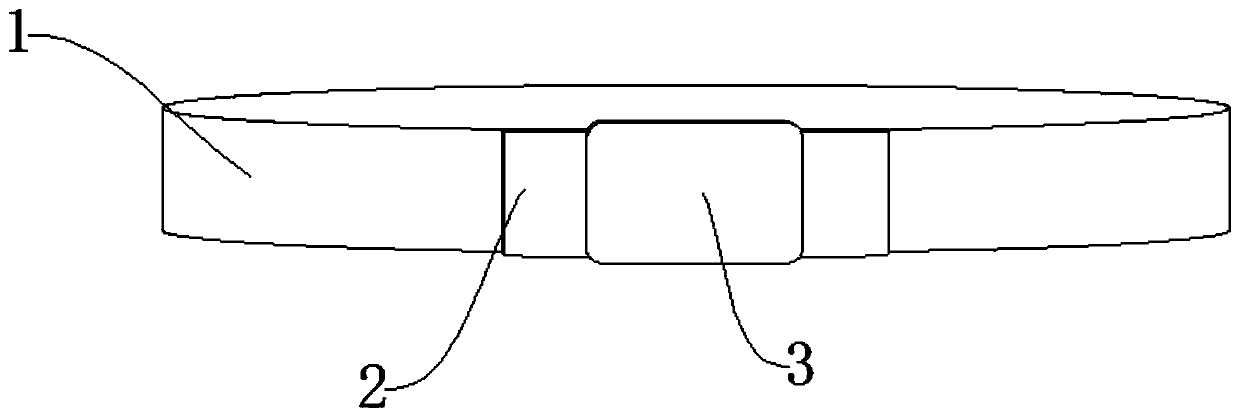

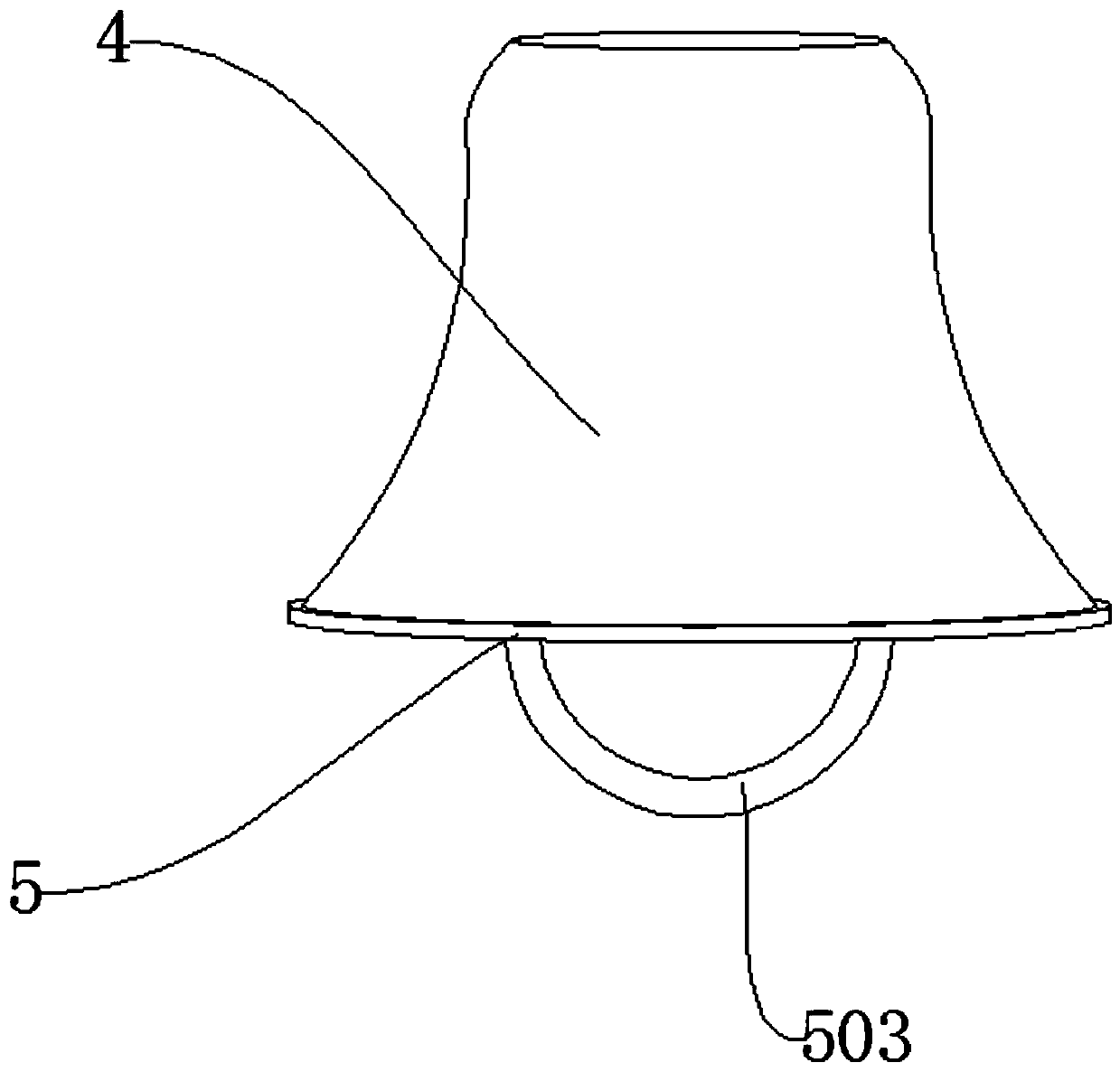

3D integrally-formed mask

PendingCN111227385AReduce processImprove work efficiencyProtective garmentSpecial outerwear garmentsNasal bridgeStructural engineering

The invention relates to the field of hygienic products. The invention relates to a mask, in particular to a 3D integrally-formed mask. The mask comprises a mask body and ear bands arranged on the twoside edges of the mask body, and is characterized in that a folding part is arranged on the upper portion of the mask body, a telescopic part dividing the mask body into a plurality of areas is arranged on the mask body, every two adjacent areas are connected through the corresponding telescopic part, and an interlayer with a filter element is arranged in the mask body; the folding part comprisesa pressing strip channel and a nose bridge pressing strip, the nose bridge pressing strip is arranged in the pressing strip channel, the pressing strip channel is an elastic rope extending spirally,a plurality of invisible seams are formed in the elastic rope in the axial direction, and the seams of the invisible seams are smaller than the width of the nose bridge pressing strip. The mask body,the ear bands and the elastic ropes are integrally woven and formed, procedures are reduced, the working efficiency is improved, the filter element can be replaced, the mask body and the nose bridge pressing strip can be cleaned and repeatedly used, materials of the mask are saved, and the production cost is reduced.

Owner:东莞市中大纺织机械有限公司

Silkworm chrysalis protein fiber tencel blended yarn and manufacturing method thereof

The invention provides silkworm chrysalis protein fiber tencel blended yarn which is little in hairiness, high in anti-abrasion performance, strong in strength, and close to skin, beauties the skin, is ventilated, and refreshes feeling. The yarn is made of 20% of silkworm chrysalis protein fibers, 30% of tencel fibers and 50% of long stapled cotton in a compact spinning mode. The invention further provides a manufacturing method of the embedded spinning china-hemp native fiber multi-component blended yarn. The method includes the following steps: after the silkworm chrysalis protein fibers and the tencel fibers are preprocessed, the silkworm chrysalis protein fibers and the tencel fibers are respectively slivered through blowing and cotton carding processes, respectively pre-combined, mixed with long staple combed cotton three times on a drawing machine, roved, spun in a compact mode, and spooled to form the yarn.

Owner:JIANGSU YDTEX GRP LTD

Air-permeability cotton cloth medical adhesive tape and manufacturing method thereof

InactiveCN101933861ABreathability leapBreathable and comfortableSurgeryAdhesive dressingsEngineeringCotton cloth

The invention discloses an air-permeability cotton cloth medical adhesive tape and a manufacturing method thereof. The adhesive tape is manufactured by coating a hot melt adhesive or zinc oxide hot melt adhesive layer only on one side of cotton cloth and cutting the cotton cloth into segments, and is characterized in that: hot melt adhesive is coated on the side of the cotton cloth at intervals in a strip way and the intervals between the adhesive strips, which are not coated with adhesive, are 1 to 5 millimeters wide. The width of adhesive parts of the cotton cloth medical adhesive tape is equal to or more than that of the adhesive-less parts. The method of the invention greatly improves the air permeability of the cotton cloth medical adhesive tape by coating the adhesive in a strip way, so that a user is protected from allergy.

Owner:上海华舟压敏胶制品有限公司

Cold cushion

The present invention discloses a cold cushion, which comprises a cushion body, wherein the cushion body is moveably connected with a cold pad, and four corners of the cold pad are connected with the cushion body through Velcro connections. The cold cushion has characteristics of reasonable structure, gas permeation, comfort, and convenient use. In addition, the provided cold cushion is a detachable structure, such that the cold pad can be removed after cooling, and the bottom pad is used so as to effectively protect human health.

Owner:NANTONG TONGZHOU DISTRICT FIVE PICK PEAS WOVEN PLANT

Anti-bedsore medical protection pad

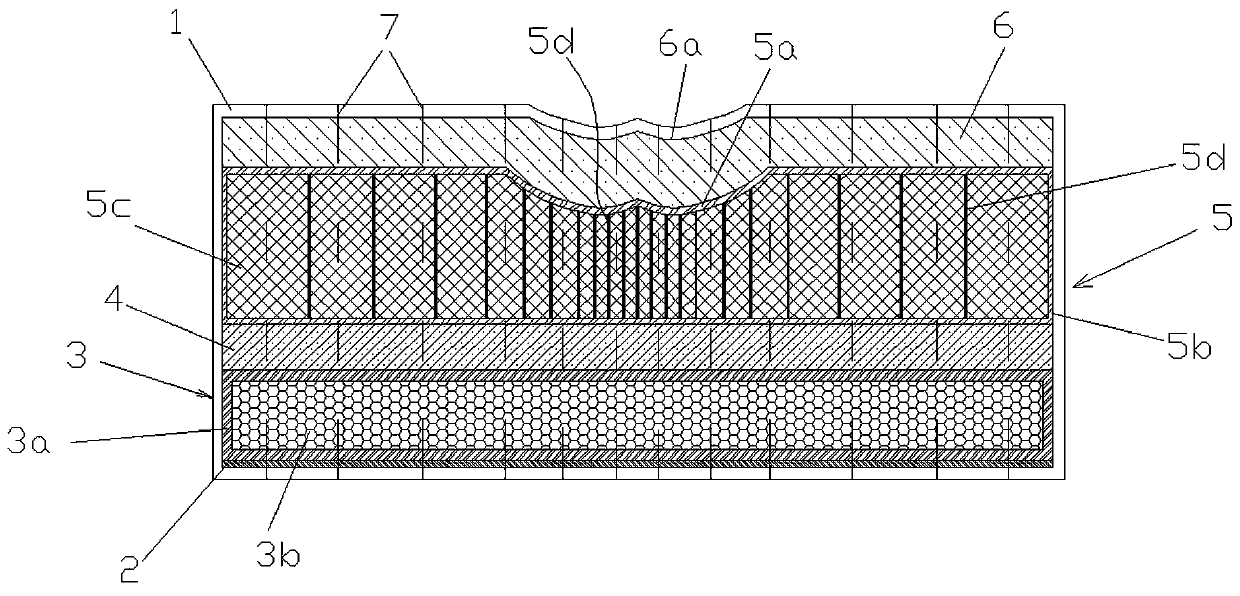

PendingCN110584922ANatural skin-friendly and non-hydrophilicReduce the chance of occurrencePersonal careSynthetic resin layered productsBiomedical engineeringPressure sores

The invention provides an anti-bedsore medical protection pad. The protection pad comprises an outer cover (1) which is characterized in that a flow extending layer (2), a water absorbing layer (3), afirst pad layer (4), a second pad layer (5) and a third pad layer (6) are sequentially arranged in the outer cover (1) from bottom to top. The protection pad has the advantages of being simple in structure, convenient to use, breathable, comfortable, capable of keeping dry for a long time, skin-friendly, capable of inhibiting bacteria and the like.

Owner:南京凡丁生物科技有限公司

Polyester mesh fabric sorting method

InactiveCN104988769ABreathable and comfortableHeating/cooling textile fabricsDyeing processPolyesterFiber

The invention discloses a polyester mesh fabric sorting method. Fabric is composed of 100% polyester fiber 75D / 72F. A finishing agent is composed of, by weight, 0.02%-0.04% of whitening agents, 0.02%-0.03% of cyanlotus E-BLN, 0.003%-0.007 % of cyanlotus E-3RL, 0.8-1.2% of levelling agents and 0.3%-0.7% of emulsion oil removing agents. The dyeing temperature ranges from 25 DEG C to 35 DEG C, the dyeing time ranges from 20 minutes to 40 minutes, the sizing temperature ranges from 160 DEG C to 200 DEG C, and the winding speed ranges from 20 m / min to 40 m / min. The manufactured polyester mesh fabric is light, graceful and soft in appearance, breathable, comfortable and suitable for serving as fabric of tops of summer clothes.

Owner:SHISHI XIANGHUA GRP

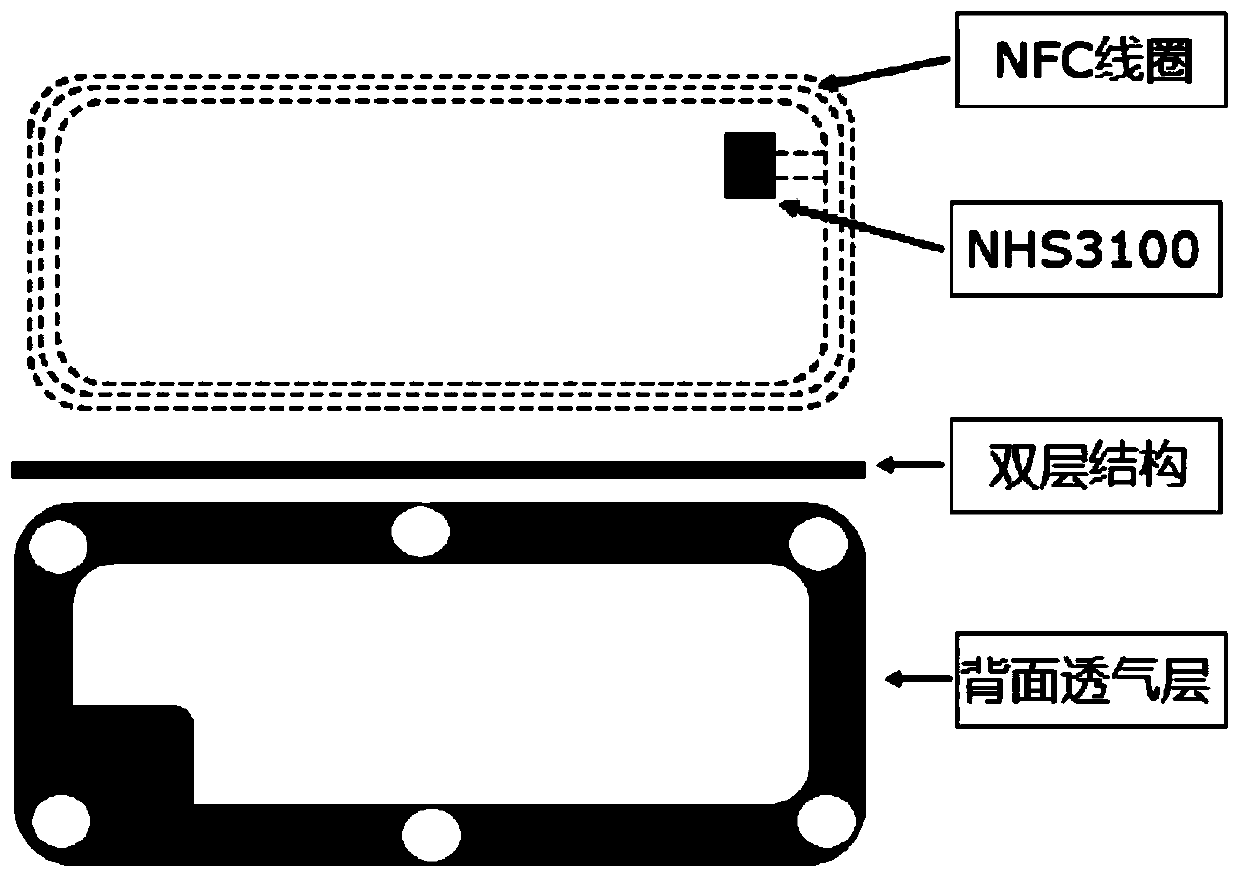

Passive wireless flexible hollow body temperature monitoring patch

ActiveCN109839199AAchieve readImplement storageThermometer detailsTransmission systemsEngineeringTemperature monitoring

The invention discloses a manufacturing method of a passive wireless flexible hollow body temperature monitoring patch. The method provided by the invention comprises the steps that a chip is directlyconnected with an antenna to construct a body temperature patch hardware circuit; a double-layer hollow body temperature patch is designed according to the shape of the hardware circuit; the upper layer adopts waterproof package; and the design of the lower layer adopts a breathable microstructure. According to the invention, comfort of the patch used for a long time is realized; the foreign bodysensation is reduced; the air permeability is improved; sweating caused by the use of the patch is prevented; in addition, the patch provided by the invention is free of a power supply, can acquire energy through a radio frequency field, and thus can be used continuously for a long time; the problems of short endurance of the existing body temperature patch and resource waste caused by one-timeuse are solved; at the same time, the patch is packaged in a flexible material; the thickness is 2 to 3mm; and the patch can be stretched and bent within a certain range, and can be in conformal contact with the skin.

Owner:SOUTHEAST UNIV

Elastic silky fabric

InactiveCN103726345ASilky fabric feelBreathable and comfortableTextiles and paperPolyesterEngineering

The invention discloses an elastic silky fabric which consists of the following component raw materials: 8 to 10 parts of polyester fibers, 4 to 6 parts of polypropylene, 1 to 3 parts of spandex, 2 to 4 parts of viscose, 4 to 6 parts of terylene, 7 to 9 parts of tribute silk and 1 to 3 parts of gabardine. The elastic silky fabric disclosed by the invention has the advantages of silky fabric hand feeling, breathability and comfort.

Owner:JIANGSU DECENT TEXTILE

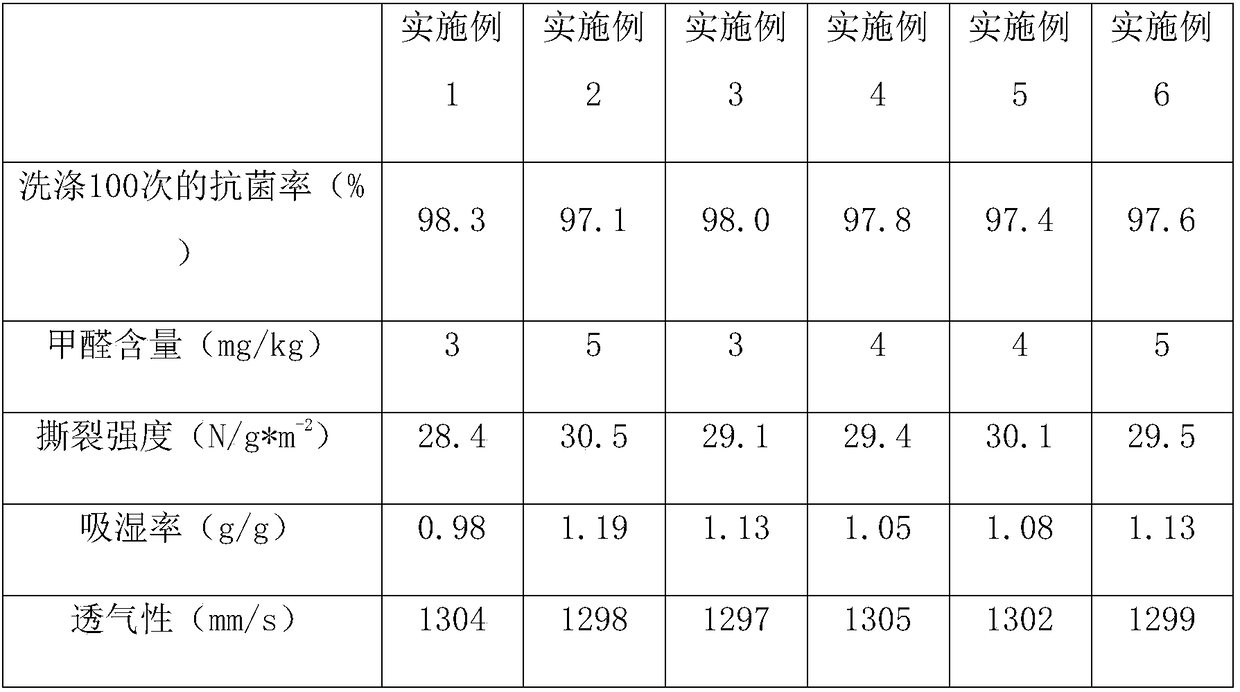

A special antibacterial textile fabric for babies

ActiveCN105239389BBreathable and comfortableGood hygroscopicityWoven fabricsVegetal fibresCooking & bakingNewborn infant

The invention provides novel antibacterial textile fabric special for infants and a preparing method thereof. The method comprises the specific operation steps that 1, lotus fibers extracted through a physical method serve as weft, cotton fibers serve as warp, double-layer plain weave is adopted as a weave structure, and weaving is carried out so that a fiber layer can be formed; 2, hydrolyzed chitosan is dissolved into water, a plant antibacterial extracting solution is added, the mixture is stirred uniformly, finally sodium alginate is added, and after sodium alginate is dissolved, transparent and uniform antibacterial viscous fluid is formed; 3, after the fiber layer prepared in the step 1 is tentered and finished, the surface of the fiber layer is coated with the antibacterial viscous fluid prepared in the step 2, and baking, washing and drying are carried out to obtain the antibacterial textile fabric special for the infants. The antibacterial property is still excellent after the prepared antibacterial textile fabric special for the infants is washed with water for 100 times, the textile fabric has excellent wet absorbing and ventilating properties, is soft and comfortable in handfeel and environmentally friendly, meets the requirement of clothes of the newborn infants and is antibacterial textile fabric special for the infants, and safety is guaranteed.

Owner:安徽京威纺织服饰有限公司

Fiber fabric

InactiveCN109007994ABreathable and comfortableHigh strengthGarment special featuresHandkerchiefsBlood pressureUltimate tensile strength

The invention discloses a fiber fabric which comprises the following raw materials in percentage by weight: 10-15% of bamboo charcoal fiber, 35-40% of apocynum fiber, 8-10% of cotton fiber, 10-15% ofbamboo fiber, 15-20% of modal fiber, 8-15% of milk fiber, and 6-12% of soybean fiber. The fiber fabric prepared by the formula is more comfortable and breathable, softer, durable and crease-resistantand is higher in strength. Meanwhile, the fabric also has the effects of preventing static electricity, reducing blood pressure, relieving asthma and reducing fat.

Owner:NANTONG HAONAN TEXTILE CO LTD

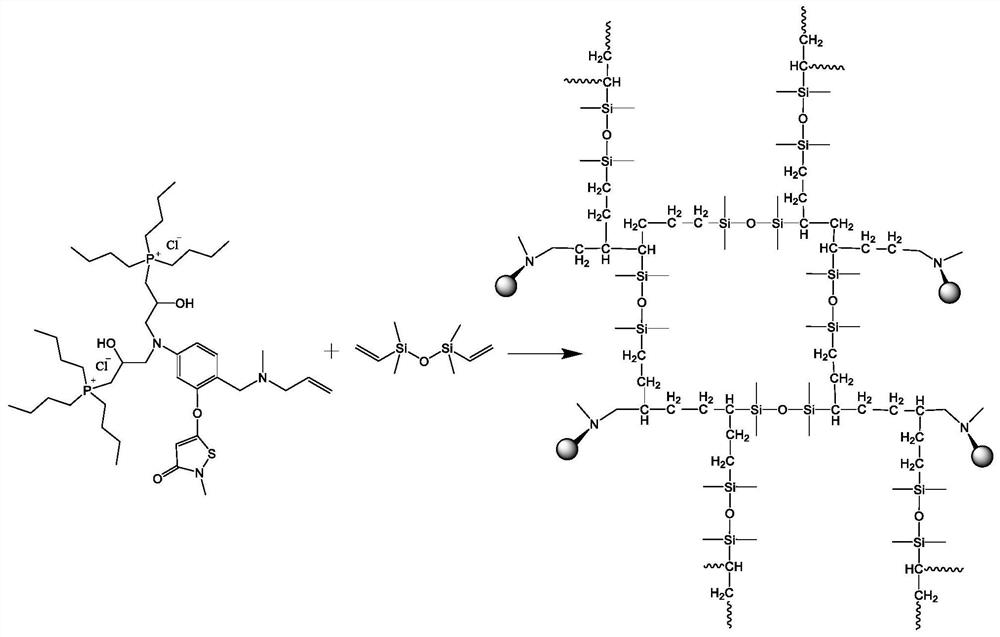

Cloth structure with electric heating warm-keeping and electrical stimulation coating and preparation method of cloth structure

ActiveCN114224595APromote recoveryImprove adhesionDevices for heating/cooling reflex pointsExternal electrodesEngineeringCross linker

The invention provides a cloth structure with an electric heating warm-keeping and electrical stimulation coating and a preparation method thereof.The cloth structure comprises base cloth, an electric heating coating, an insulating layer and the electrical stimulation coating, the base cloth is provided with a first surface, the electric heating coating is attached to the first surface, and the insulating layer is attached to the first surface; the electrical stimulation coating is attached to the electric heating coating through an insulating layer, the electric heating coating and the electrical stimulation coating are respectively and electrically connected with a control system, the control system controls the electric heating coating to heat, and the control system controls the electrical stimulation coating to output 0-15mA current; raw materials of the electric heating coating comprise dendritic silver, flaky silver material powder and a cross-linking agent, and raw materials of the electric stimulation coating comprise dendritic silver material powder and a cross-linking agent. The fabric structure has electrical stimulation and electric heating functions, can perform electrical stimulation and hot compress on acupuncture points of a human body, has the effects of relieving, relaxing, relieving fatigue and the like, and also has the advantages of lightness, thinness, breathability, high comfort, washing resistance and the like.

Owner:徐州市海格德生物科技有限公司

Polyoxymethylene alloy having shape memory and low melting point temperature and processing technology thereof

The invention relates to a polyoxymethylene alloy having shape memory and low melting point temperature and a processing technology thereof. Low-temperature thermoplastic material products on the markets basically use polycaprolactone as the main raw material, are expense in price and difficult to widely apply. The polyoxymethylene alloy having shape memory and low melting point temperature comprises the components by weight : 40-75 parts of polyoxymethylene, 20-50 parts of shape memory polyurethane, 10-35 parts of acrylonitrile / butadiene / styrene copolymer and 5-10 parts of compatibilizer. The invention can substitute a traditional plaster bandage to be used medically.

Owner:HEILONGJIANG UNIV

Novel ventilating adhesive-free navel patch

PendingCN111420260ALarge fitting surfaceLarge treatment areaMedical applicatorsAbsorbent cotton gauzeHuman body

The invention discloses a novel ventilating adhesive-free navel patch. The ventilating adhesive-free navel patch comprises a emulsion-type pill, a nail cover and an elastic fixing belt, the nail coveris arranged at the bottom end of the emulsion-type pill, a medical absorbent cotton gauze block is arranged on one side of the emulsion-type pill when in use, and the elastic fixing belt is arrangedabove the medical absorbent cotton gauze block. The ventilating adhesive-free navel patch has the beneficial effects that: the ventilating adhesive-free navel patch has a novel structure; by adoptingthe pills with a emulsion-type structure, the bonding surface of the emulsion-type pill and the navel is ensured to be larger; the whole navel can be fully contacted with the emulsion-type pill; the treatment area of the medicines is greatly improved; the medicine coverage area is as high as about 98 percent; meanwhile, the use comfort of a human body is improved; the problems of insufficient contact, uncomfortable bonding and low medicine effect of spherical pills are solved; the medicine effect is fully exerted; the efficacy of the whole health-care pill is improved; and the health of the human body is ensured.

Owner:深圳市纳鑫达通讯设备有限公司

A kind of preparation technology of imitation bamboo fiber fabric

ActiveCN111334916BMoisture absorption and quick dryingBreathable and comfortableWeft knittingGroup 5/15 element organic compoundsPolymer sciencePolyvinyl alcohol

The invention discloses a preparation process of imitation bamboo fiber fabric, and the specific preparation process is as follows: in the first step, the antibacterial water-absorbing polymer and polyvinyl alcohol are simultaneously added to the screw extruder according to the mass ratio of 10:0.47-0.55 Carry out melt extruding, obtain spinning polymer; Second step, the spinning polymer prepared in the first step is added in melt spinning machine and carry out melt spinning, obtain fiber silk, then add the fiber silk obtained into 95- Cook in hot water at 100°C for 5-6 hours, then remove, dry in a drying room at 50-60°C to obtain imitation bamboo fibers, and then use the imitation bamboo fibers to prepare imitation bamboo fiber fabrics. The fabric prepared by the invention not only has the properties of bamboo fiber antibacterial and antibacterial, moisture absorption and quick drying, breathable and comfortable, but also has high strength, can withstand repeated cleaning and use, improves the service life, and solves the problem of short service life of existing bamboo fiber fabrics. shortcoming.

Owner:江苏罗曼罗兰集团有限公司

Preparation method of long-acting mosquito-repelling insect-expelling heat-moisture comfortable fabric

PendingCN112522943AMosquito and insect repellent function is long-lasting and effectiveThe preparation method is green, environmentally friendly and pollution-freeBiocideBiochemical fibre treatmentEnvironmental geologyChinese herbology

The invention discloses a preparation method of a long-acting mosquito-repelling insect-expelling heat-moisture comfortable fabric, and belongs to the field of fiber production. The preparation methodof the long-acting mosquito-repelling insect-expelling heat-moisture comfortable fabric comprises the following steps preparing traditional Chinese medicine components, pretreating the surface of wood pulp viscose fiber, and preparing the mosquito-repelling insect-expelling wood pulp viscose fiber. The preparation method provided by the invention is green, environmental-friendly and free of pollution, and the prepared mosquito-repelling insect-expelling fiber is green and natural, has no any side effect, and has remarkable long-acting mosquito-repelling insect-expelling effects and comfortable and breathable effects.

Owner:无锡市利诚纺织科技有限公司 +1

High-permeability fabric

InactiveCN104997214AGuaranteed warmthImprove breathabilityLayered productsProtective garmentStructural engineeringMechanical engineering

Owner:HUZHOU NANXUN JINJIBAO TEXTILE

Acid-resistant finishing method for cotton fabric

InactiveCN105568667APrevent wettingAvoid osmosisGrip property fibresVegetal fibresCyclohexanoneCis-Butenedioic Acid

The invention discloses an acid-resistant finishing method for cotton fabric. The method comprises the following steps: firstly adding water to a finishing agent to prepare a steeping liquor; putting the fabric into the steeping liquor for padding, wherein the pick-up ratio is 45%-70%; and finally washing the fabric for 2-3 times, and then dewatering and drying the fabric, wherein the finishing agent is prepared from the following components in parts by weight: 5-6 parts of dimethyl terephthalate, 5-10 parts of maleic anhydride, 1-6 parts of acrylamide, 3-6 parts of n-butyl titanate, 14-18 parts of benzyl trimethyl ammonium chloride, 7-9 parts of bunge corydalis herb powder, 3-7 parts of didecyl dimethyl ammonium chloride, 22-25 parts of ethylene glycol, 5-9 parts of vinyl trimethoxysilane, 1-8 parts of an isocyanate tripolymer, 2-6 parts of sodium xylene sulfonate, 3-6 parts of cyclohexanone, 1-3 parts of talcum powder and 1-2 parts of zinc acetate. The finishing method disclosed by the invention is capable of preventing the cotton fabric from being wetted and infiltrated and withstanding relatively strong corrosion, and has the advantages of being breathable, comfortable, soft, light, easy to wash and the like.

Owner:HUZHOU XINCHUANG SILK

Method for manufacturing polyurethane (PU) oak health-care soles

The invention discloses a method for manufacturing polyurethane (PU) oak health-care soles. The method comprises the following steps of: mixing oak particles and Chinese medicine particles; performing heating treatment on the mixed oak particles and Chinese medicine particles in a container at the temperature of 60 DEG C for 4 to 6 hours; and putting the oak particles and the Chinese medicine particles which are subjected to the heating treatment into a PU filling machine, combining a PU raw material A with a PU raw material B through a chemical reaction, and thus obtaining the soles with different thicknesses. The oak particles and the Chinese medicine particles are added into PU materials to manufacture the soles, so that the soles have low-carbon, environment-friendly, comfortable, ventilated and fatigue-relieving functions; and due to the addition of the Chinese medicine particles of different types, various foot diseases and other diseases can be prevented and treated.

Owner:吴隆斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com