Silkworm chrysalis protein fiber tencel blended yarn and manufacturing method thereof

A technology of silkworm chrysalis protein fiber and tencel cotton, which is applied in the direction of yarn, textile and paper making, can solve the problems of low strength, excessive hairiness, poor spinnability, etc., and achieve the effect of increased strength, multiple functions and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Spinning process

[0033] 1. Selection of raw materials:

[0034] The silkworm chrysalis protein fiber specification is 1.5D*38mm, the tencel fiber is 1.2D*38mm, and the cotton fiber is 137A Xinjiang long-staple cotton.

[0035] 2. Process flow:

[0036] ①Silkworm chrysalis protein fiber: FA002A cotton grabbing machine→A035E mixed cotton opener→FA106 cotton opener→A092A cotton feeder→A076C lapping machine→FA203A carding machine→JWF1310 pre-draw frame→

[0037] ②Tencel fiber: FA002A catching machine→A035E mixed opener→FA106 opener→A092A feeder→A076C lapping machine→FA203A carding machine→JWF1310 pre-draw frame→

[0038] ③Long-staple cotton: FA002A catching machine→A035E mixed opener→FA106 opener→A092A feeder→A076C coiler→A186D carding machine→JWF1310 pre-drawframe→FA360 coiler→F1268A finish Combing →

[0039] ①+②+③JWF1310 blending 1→JWF1310 blending 2→FA326 final blending→FA494 roving frame→DTM129 compact spinning frame→No21C winding machine.

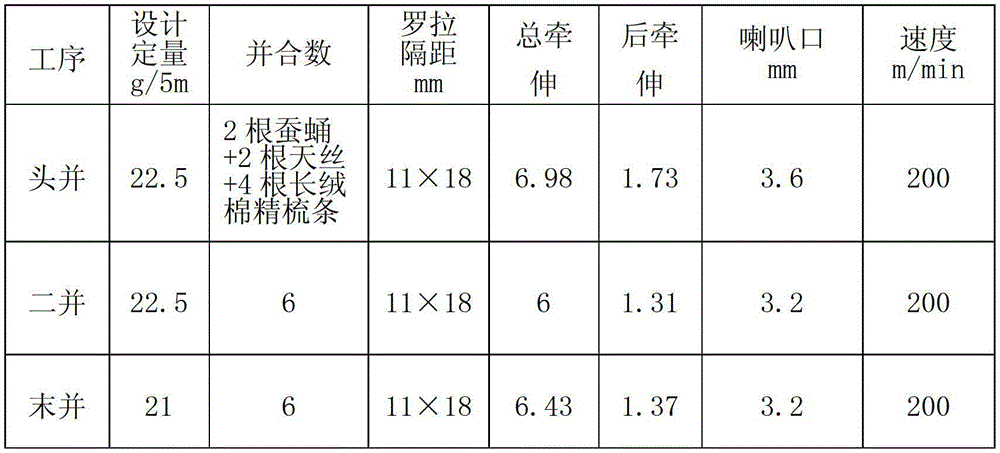

[0040]2. Main tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com