Far infrared hollow thermal yarns and processing method

A processing method, far-infrared technology, applied in the field of textile fabrics, can solve the problems of heavy thermal clothing, inconvenient wearing activities, lack of aesthetic feeling, etc., achieve good thermal performance, high practical value, and reduce the effect of winding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

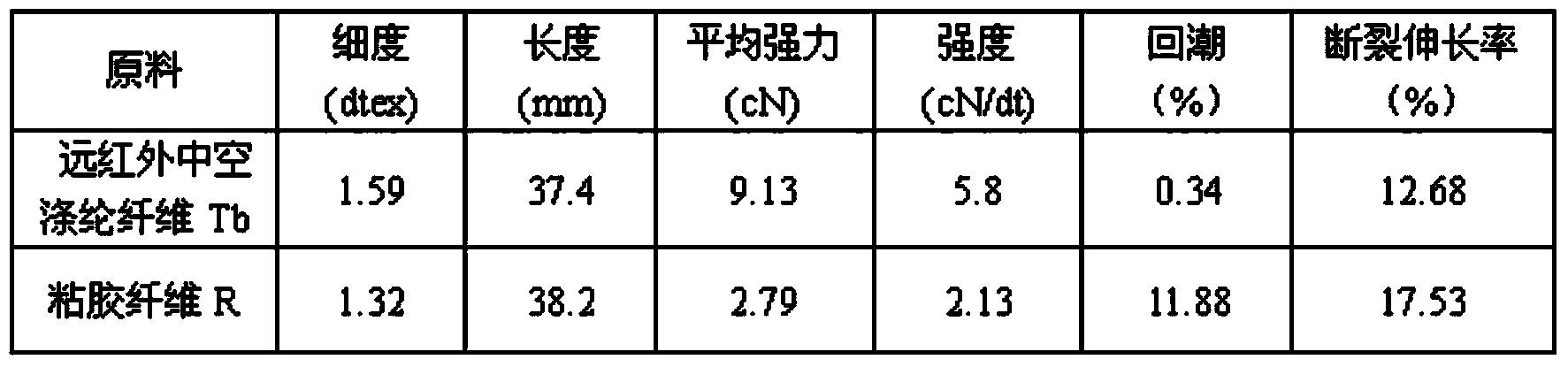

[0029] A far-infrared hollow thermal insulation yarn, said far-infrared hollow thermal insulation yarn is composed of a blend of 80% by weight far-infrared hollow polyester fiber and 20% viscose fiber, and the specification of the far-infrared hollow polyester fiber is 1.56 dtex×38mm, the specification of the viscose fiber is 1.33dtex×38mm.

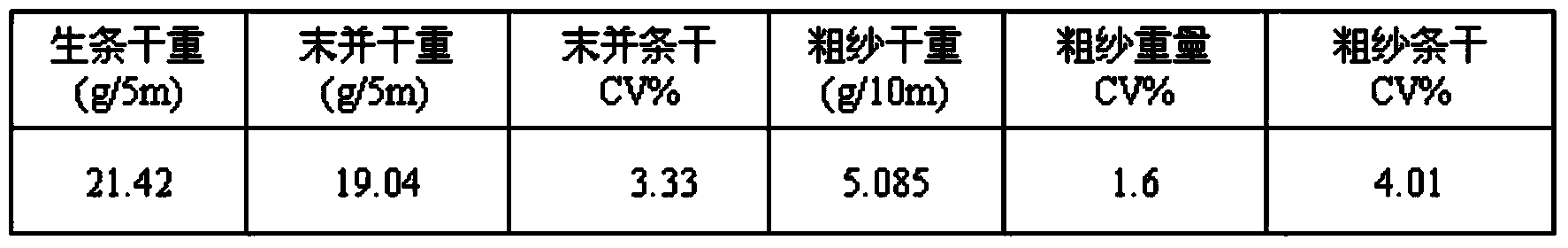

[0030] The processing method of far-infrared hollow warm yarn includes cleaning, carding, drawing, roving, spun yarn and winding process. Because both fibers are chemical fibers, they have good uniformity and do not contain impurities. The viscose fiber is directly mixed with raw materials in the blowing process according to the yarn ratio, and made into cotton rolls for later production use. The basic technological process is:

[0031] Far-infrared hollow polyester fiber / viscose fiber: A002C grabbing machine → A035A mixed opener → A036 opener → A092A box feeder → A076C roll machine → A186C carding machine → FA311F draw frame (two-pass )→FA4...

Embodiment 2

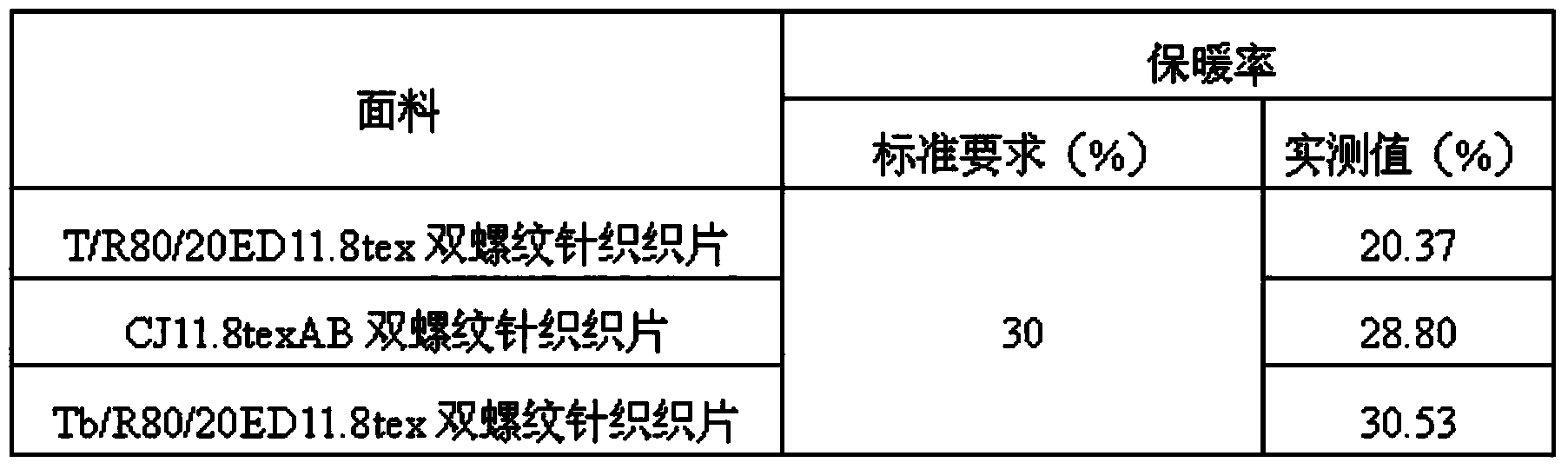

[0066] The far-infrared hollow warm yarn of Example 2 is composed of a blend of 80% by weight far-infrared hollow polyester fiber and 20% viscose fiber. The far-infrared material in the far-infrared hollow polyester fiber is far-infrared ceramic powder. The content of infrared ceramic powder is 10% of the total fiber weight, and the far-infrared radiation wavelength of the far-infrared ceramic powder is 4 μm-14 μm; the far-infrared hollow polyester fiber is a single-hole hollow polyester fiber, and the average value of the single-hole hollow polyester fiber The hollow rate is 30%-40%, and the rest is the same as in Example 1. In this embodiment, hollow polyester fiber is used, and its heat retention performance and service life are significantly improved compared to Example 1. The measured heat retention rate reaches 31.2%, which is slightly improved compared with Example 1.

Embodiment 3

[0068] The two ends of the single hole in the hollow polyester fiber of Example 3 are closed structures, and the length of the closed section is 0.5 mm-1 mm, and the rest is the same as Example 2. This embodiment uses a hollow polyester fiber with a single-hole and closed-end structure, and its warmth retention performance and service life are significantly improved compared with Example 2, and its warmth retention rate is measured to reach 33.6%, which is significantly improved compared with Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com