A special antibacterial textile fabric for babies

A technology for textile fabrics and babies, which is applied in the field of special antibacterial textile fabrics for babies and its preparation, can solve the problems of newborn skin screening, the fabric cannot meet the needs of special physiological characteristics of newborn babies, etc. The effect of strong hygroscopic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

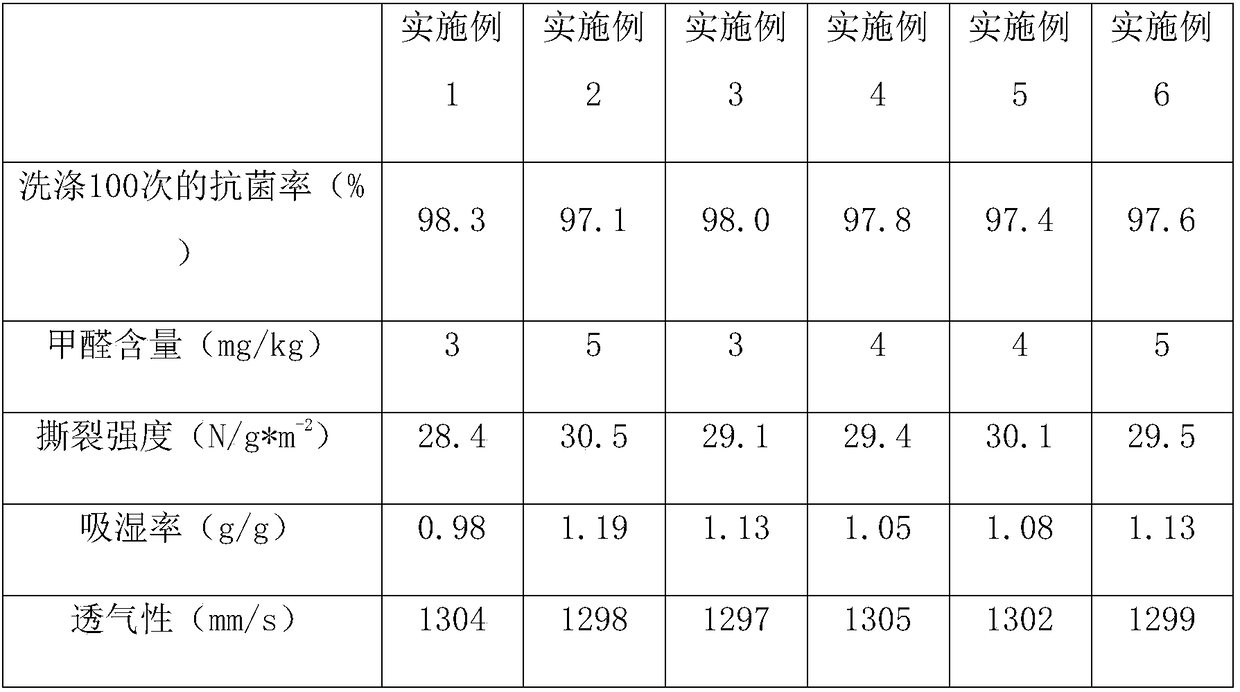

Examples

Embodiment 1

[0030] (1) will be extracted through physical method, the flat ribbon-shaped multifilament lotus fiber that is formed by 4 monofilaments of 3 μm is as weft thread, and the cotton fiber of 13tex is as warp thread, and the consumption ratio of lotus fiber and cotton fiber is 1:1.5, Double-layer plain weave is used as the tissue structure, and a fiber layer of 189g / ㎡ is formed by weaving.

[0031] (2) In parts by weight, 20 parts of chitosan with a molecular weight of 2000 after hydrolysis are dissolved in water, 15 parts of aloe extract are added, stirred evenly, and finally 35 parts of sodium alginate are added. Dissolve to form a transparent and uniform antibacterial viscous liquid.

[0032] (3) After the fiber layer prepared by step (1) is tentering, the antibacterial viscous liquid prepared by step (2) is coated on the surface of the fiber layer, dried, washed, and dried to obtain the special antibacterial textile fabric for babies, Wherein the thickness of the antibacteria...

Embodiment 2

[0034] (1) will be extracted through physical method, the flat strip multifilament lotus fiber that is made up of 8 monofilaments of 4 μm is as weft thread, and the cotton fiber of 15tex is as warp thread, and the consumption ratio of lotus fiber and cotton fiber is 1:2.7, Double-layer plain weave is used as the tissue structure, and a fiber layer of 204g / ㎡ is formed by weaving.

[0035] (2) In parts by weight, 35 parts of chitosan with a molecular weight after hydrolysis of 5000 are dissolved in water, 30 parts of tea extract and honeysuckle extract are added, stirred evenly, and finally 55 parts of sodium alginate are added, After the sodium alginate is dissolved, a transparent and uniform antibacterial viscous liquid is formed.

[0036] (3) After the fiber layer prepared by step (1) is tentering, the antibacterial viscous liquid prepared by step (2) is coated on the surface of the fiber layer, dried, washed, and dried to obtain the special antibacterial textile fabric for b...

Embodiment 3

[0038] (1) Extracted by physical methods, the flat ribbon-shaped multifilament lotus fiber composed of 5 3.2 μm monofilaments is used as the weft thread, and the cotton fiber of 14tex is used as the warp thread, and the ratio of the lotus fiber to the cotton fiber is 1:1.8 , using double-layer plain weave as the structure, weaving to form a fiber layer of 193g / ㎡.

[0039](2) In parts by weight, dissolve 25 parts of chitosan with a molecular weight of 3000 after hydrolysis in water, add 20 parts of honeysuckle extract, stir evenly, finally add 40 parts of sodium alginate, and wait for sodium alginate to Dissolve to form a transparent and uniform antibacterial viscous liquid.

[0040] (3) After the fiber layer prepared by step (1) is tentering, the antibacterial viscous liquid prepared by step (2) is coated on the surface of the fiber layer, dried, washed, and dried to obtain the special antibacterial textile fabric for babies, Wherein the thickness of the antibacterial finishi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com