A kind of preparation technology of imitation bamboo fiber fabric

A preparation process and fiber technology, which is applied in the field of preparation process of imitation bamboo fiber fabrics, can solve the problems of short service life and achieve the effects of improved service life, uniform antibacterial performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

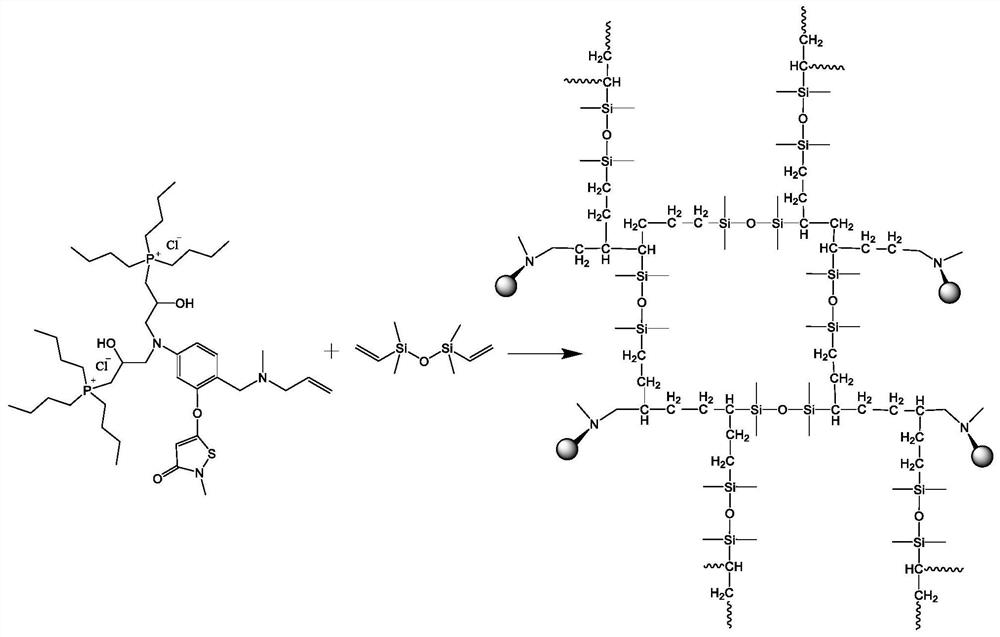

Image

Examples

Embodiment 1

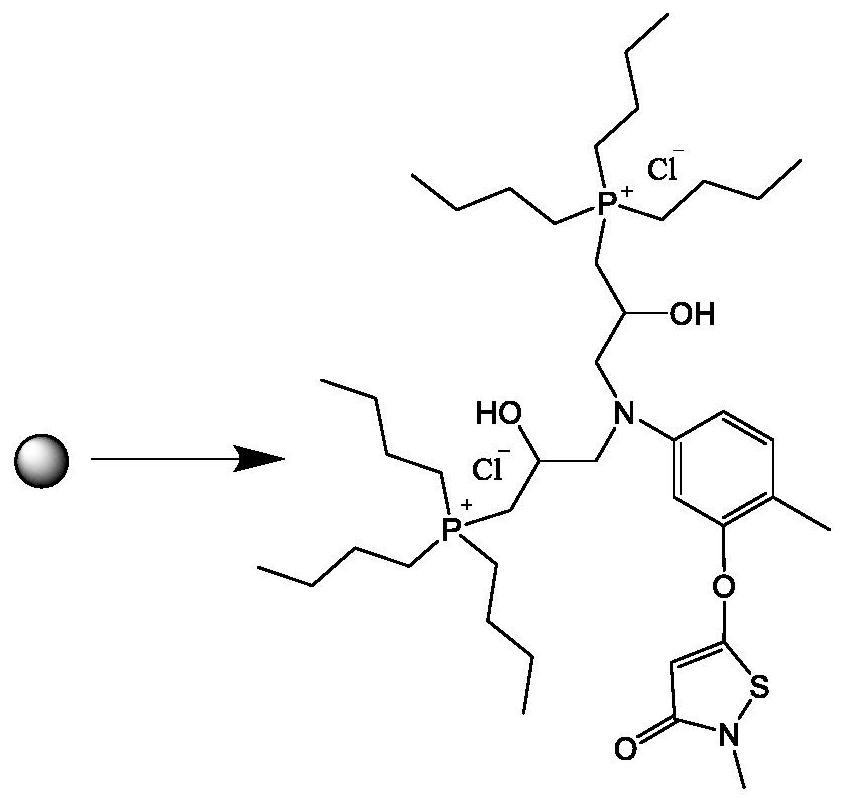

[0025] The specific preparation process of the antibacterial moisture-absorbing monomer is as follows:

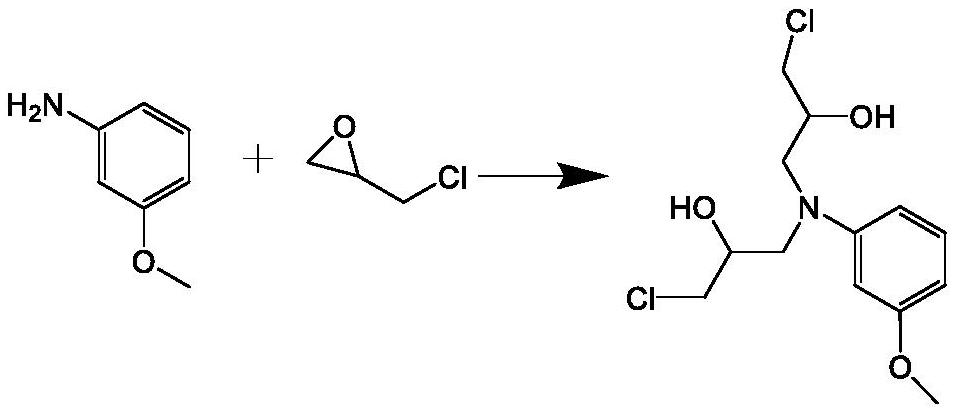

[0026] Step 1: Weigh 1kg of m-aminoanisole and 3L of ethanol and add them into the reaction vessel and stir evenly, then add 1.58kg of epichlorohydrin into it, heat to 60-65°C for 3-4h and then heat up to 80-85°C React for 2-3h, then evaporate and concentrate, then carry out vacuum distillation to obtain bishydroxychloroanisole, the reaction structure is as follows;

[0027]

[0028] Step 2, add 1kg of bishydroxychloroanisole, 730g of trimethylchlorosilane and 2L of dichloromethane into the reaction vessel at the same time, raise the temperature to 60-65°C for reflux reaction for 8-9h, cool the product and add it to deionized water Stir evenly, then extract with ether, wash the obtained organic phase with water, dry with anhydrous sodium sulfate, and then carry out vacuum distillation to obtain the product bishydroxychlorophenol;

[0029] Step 3: Weigh 1.32kg of tributy...

Embodiment 2

[0036] The specific preparation process of the antibacterial moisture-absorbing monomer is as follows:

[0037] Step 1, weigh 1kg of m-aminoanisole and 3L of ethanol and add them into the reaction vessel and stir evenly, then add 238g of propylene oxide into it, heat to 60-65°C for 3-4h, then add 0.78kg of epoxy into it Chloropropane, heated up to 80-85 °C for 2-3 hours, then evaporated and concentrated, then distilled under reduced pressure to obtain bishydroxychloroanisole, the reaction structure is as follows;

[0038]

[0039] Step 2, add 1kg of bishydroxychloroanisole, 730g of trimethylchlorosilane and 2L of dichloromethane into the reaction vessel at the same time, raise the temperature to 60-65°C for reflux reaction for 8-9h, cool the product and add it to deionized water Stir evenly, then extract with ether, wash the obtained organic phase with water, dry with anhydrous sodium sulfate, and then carry out vacuum distillation to obtain the product bishydroxychlorophen...

Embodiment 3

[0047] The specific preparation process of the antibacterial moisture-absorbing monomer is as follows:

[0048] Step 1: Weigh 1kg of m-amino-anisole and 3L of ethanol into the reaction vessel and stir evenly, then add 472g of propylene oxide into it, heat to 60-65°C for 3-4h, then heat up to 80-85°C React for 2-3 hours, then evaporate and concentrate, then carry out vacuum distillation to obtain bishydroxyanisole, the reaction structure is as follows;

[0049]

[0050] Step 2, add 1kg of bishydroxyanisole, 730g of trimethylchlorosilane and 2L of dichloromethane into the reaction vessel at the same time, raise the temperature to 60-65°C for reflux reaction for 8-9h, cool the product and add it into deionized water and stir evenly , and then extracted with ether, the obtained organic phase was washed with water and dried with anhydrous sodium sulfate, and then subjected to vacuum distillation to obtain the product bishydroxyphenol;

[0051] Step 3: Weigh 458g of bromoethane,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com