A kind of reinforced fiberglass and its manufacturing method

A manufacturing method and technology of FRP, applied to chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of low shear strength between easily deformed layers, and achieve long product life, not easy to deform, Anti-aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

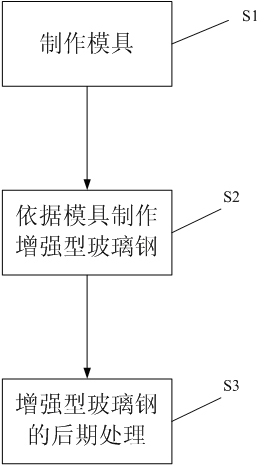

Method used

Image

Examples

Embodiment

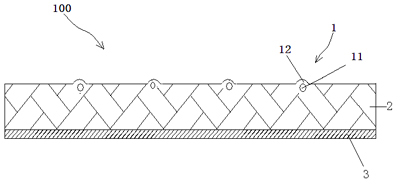

[0042] Such as figure 1 , a reinforced FRP 100, comprising: a gel coat layer 3 on the surface, a glass fiber layer 2 in the middle, and a rib layer 1 on the bottom.

[0043] For ease of description, this embodiment assumes that it is a cuboid with a surface area of 40mm*50mm and a thickness of about 10mm. This set of data is only for the convenience of describing the present invention, and the present invention is not limited by the data.

[0044] A fiberglass layer 2 is laid on a gel coat layer 3 comprising several layers of resin-impregnated fiberglass. In this embodiment, the glass fiber layer 2 includes five layers of glass fibers.

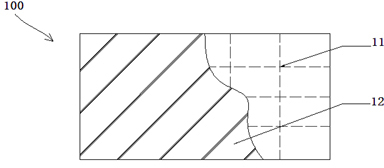

[0045] Such as figure 2 , The reinforcing rib layer 1 is laid on the glass fiber layer 2, which includes several reinforcing ribs 11 soaked with resin, and several layers of glass fibers 12 soaked with resin for wrapping the reinforcing ribs. Several reinforcing ribs are distributed and arranged in any direction. In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com