Glass fiber reinforced plastic processing technology

A processing technology, FRP technology, applied in the direction of glass/slag layered products, laminated, layered products, etc., can solve problems such as air pollution, achieve the effect of reducing production costs and solving surface quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

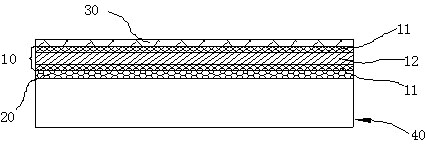

[0030] In Example 1, when the thickness of the resin glass fiber layer 20 is 3mm, the thickness of the core mat is 2mm, the layer thickness of the chopped strand mat is 0.5mm, and the curing molding time at 60°C is 3.5 hours, and at 65°C The curing molding time under the condition is 3.2 hours, and the curing molding time under the condition of 70° C. is 3 hours.

Embodiment 2

[0031] In Example 2, when the thickness of the resin glass fiber layer 20 is 4mm, the thickness of the core mat is 3mm, the layer thickness of the chopped strand mat is 0.5mm, and the curing molding time at 60°C is 3.8 hours, and at 65°C The curing molding time under the condition is 3.5 hours, and the curing molding time under the condition of 70° C. is 3.2 hours.

Embodiment 3

[0032] When the thickness of the resin glass fiber layer 20 in embodiment 3 is 5mm, the thickness of the strong core mat is 4mm, the layer thickness of the chopped strand mat is 0.5mm, the curing molding time at 60°C is 4 hours, and at 65°C The curing molding time under the condition of 3.4 hours, and the curing molding time under the condition of 70 ℃ is 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com