Preparation method of multifunctional super-hydrophobic coating with mechanical stability

A technology of super-hydrophobic coating and mechanical stability, applied in coatings, antifouling/underwater coatings, and biocide-containing paints, etc. Effects of hydrophobic properties, improved mechanical stability and bacteriostatic ability and photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

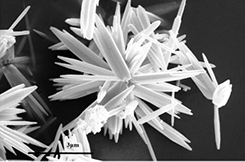

Image

Examples

specific Embodiment approach 1

[0016] Embodiment 1: The preparation method of a multifunctional superhydrophobic coating with mechanical stability in this embodiment is carried out according to the following steps:

[0017] 1. Dissolve zinc nitrate and potassium hydroxide in deionized water, slowly add the zinc nitrate solution dropwise to the potassium hydroxide solution, stir magnetically for 30-60min, and then transfer the solution to a Teflon reactor at 80-100℃ The reaction was carried out for four hours, and the obtained white powder was centrifuged and dried;

[0018] 2. Add 2-5g of the powder in step 1 to the mixed solution of absolute ethanol and tridecafluorooctyltriethoxysilane, stir magnetically for four hours, and finally dry the modified zinc oxide particles for later use ;

[0019] 3. Add polydimethylsiloxane and n-hexane into the beaker in a certain proportion and stir well, then add the modified zinc oxide into the mixture for ultrasonic dispersion for 30-50 minutes, and finally spray with ...

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 2, the ratio of the mixed solution of absolute ethanol and tridecafluorooctyltriethoxysilane is changed from 100:1-2 to 150:1 -2. Others are the same as the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: in step 3, the ratio of zinc oxide to polydimethylsiloxane is changed from the original 1:1-3 to 2:1-3 , and others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com