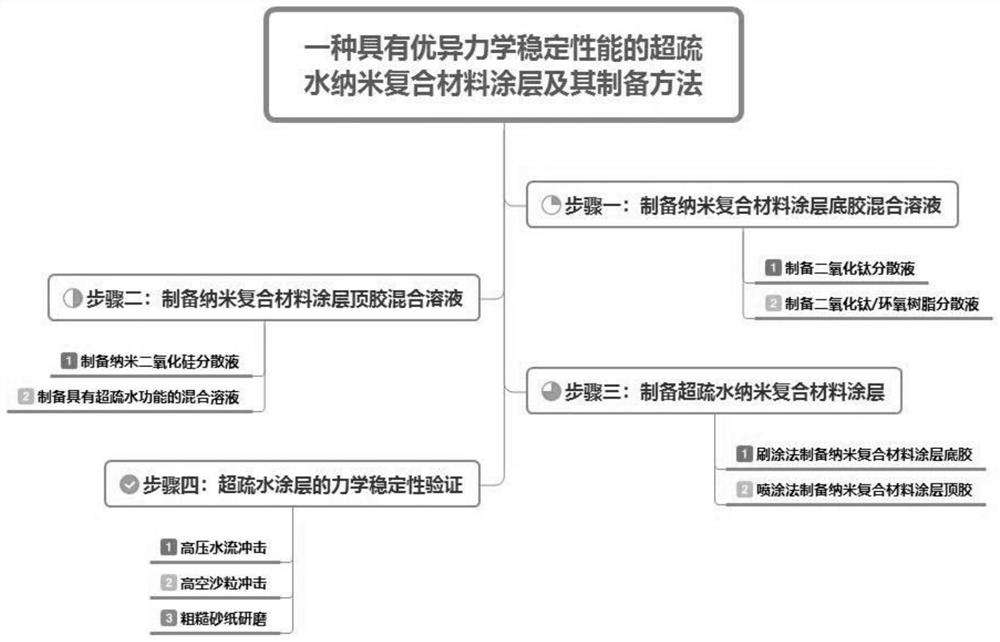

Super-hydrophobic nanocomposite coating with excellent mechanical stability and preparation method thereof

A nano-composite material and technology for stabilizing performance, applied in coatings, epoxy resin coatings, devices for coating liquids on surfaces, etc. It is not obvious and other problems, and achieves the effects of excellent mechanical toughening and interfacial hydrophobicity, excellent hydrophobicity and lubricating properties, high temperature resistance and low density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

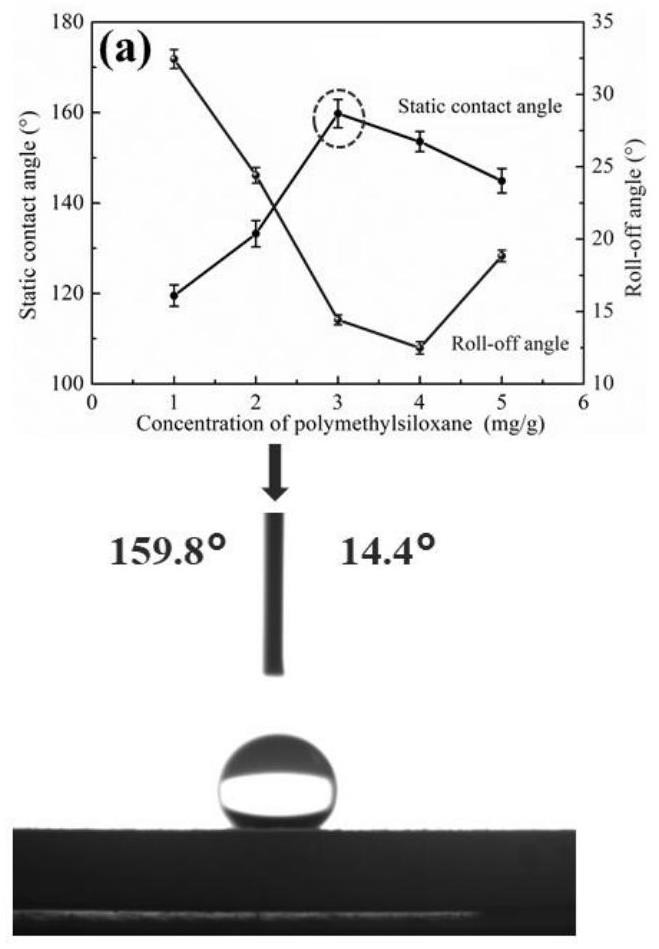

[0054] In this example, the influence of different concentrations of polymethylsilsesquioxane on the hydrophobic properties of the coating was discussed. The specific operation process is as follows:

[0055] Weigh 5 parts of 500mg epoxy resin, 172mg epoxy curing agent and 100g absolute ethanol into 5 beakers, then add 100mg, 200mg, 300mg, 400mg and 500mg of polymethylsilsesquioxane respectively. , respectively, ultrasonically stirred to obtain coating glue solutions with different concentrations of polymethylsilsesquioxane, and the sample names were marked according to the amount of polymethylsilsesquioxane added relative to the mass concentration of ethanol solvent, which were 1 mg / g, 2 mg / g, 3 mg / g, 4 mg / g and 5 mg / g.

[0056] Then use a 0.2mm spray diameter to spray the coating solution of different polymethylsilsesquioxane concentrations on the substrate evenly, the distance between the nozzle and the substrate is 200mm, the amount of each spraying solution is controlled ...

Embodiment 2

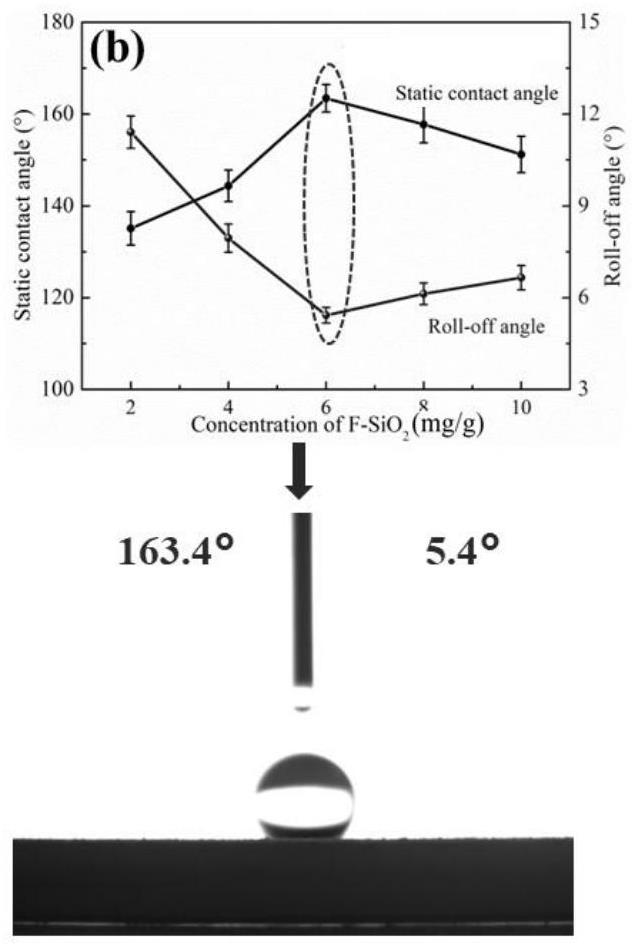

[0060] This example discusses the influence of different silica concentrations on the hydrophobic properties of the coating, and the specific operation process is as follows:

[0061] Weigh 5 parts of 500mg epoxy resin, 172mg epoxy curing agent and 100g absolute ethanol and place them in 5 beakers respectively, then add 200mg, 400mg, 600mg, 800mg and 1000mg of silicon dioxide respectively, and stir ultrasonically evenly. Coating glue solutions with different silica concentrations were obtained, and the sample names were marked according to the amount of silica added relative to the mass concentration of the ethanol solvent, which were 2mg / g, 4mg / g, 6mg / g, 8mg / g and 10mg / g respectively. .

[0062] Then use a 0.2mm spray diameter to spray the coating solution of different silica concentrations on the substrate evenly. The distance between the nozzle and the substrate is 200mm. The amount of the spray solution is controlled at 1mL each time. Dry in an oven at 60°C for 3 hours, r...

Embodiment 3

[0065] This example discusses the influence of different spraying times on the hydrophobic properties of the coating, and the specific operation process is as follows:

[0066] Add 600 mg of silicon dioxide to 100 g of absolute ethanol, add 300 mg of polymethylsilsesquioxane and stir evenly, then add 500 mg of epoxy resin and 172 mg of epoxy curing agent, and ultrasonically stir to obtain a coating glue solution.

[0067] Then use a 0.2mm spray diameter spray pen to spray the coating glue solution on the substrate evenly. The spraying times for different substrates are 1 layer, 2 layers, 3 layers..., 10 layers. The distance between each spray nozzle and the substrate is 200mm, and the amount of each spraying solution is controlled at 1mL. In multi-layer spraying, each layer is uniformly sprayed and then moved to a 60°C oven for 3 hours. Finally, the coatings with different spraying times are moved to a 100°C oven for 6 hours to dry to obtain different sprays. number of coats. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com