Spraying type polyurethane waterproof coating as well as preparation method and construction method thereof

A polyurethane waterproof and coating technology, which is applied in polyurea/polyurethane coatings, coatings, infrastructure engineering, etc., can solve the problem that polyurethane waterproof coatings cannot have ultra-high strength and ultra-high toughness at the same time, and achieve high strength, high toughness, The effect of super high toughness

Pending Publication Date: 2022-04-12

四川迈铁龙科技有限公司 +1

View PDF10 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0009] The purpose of the present invention is to provide a spray-on polyurethane waterproof coating and its preparation method and construction method, so as to solve the technical problem that the polyurethane waterproof coating in the prior art cannot have both ultra-high strength and ultra-high toughness

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

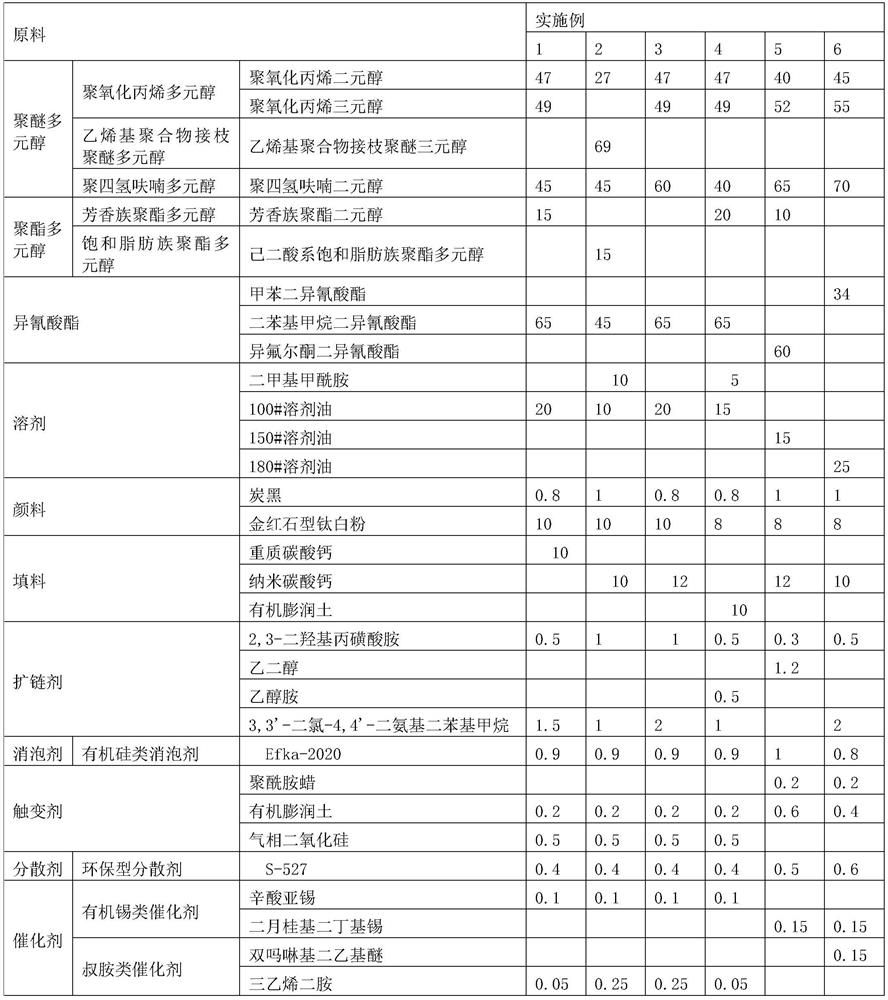

[0043] Embodiment 1: polyoxypropylene glycol 500, polyoxypropylene trihydric alcohol 1200, polytetrahydrofuran glycol 2500;

Embodiment 2

[0044] Embodiment 2: polyoxypropylene glycol 3000, vinyl polymer graft polyether trihydric alcohol 4000, polytetrahydrofuran glycol 5000;

Embodiment 3

[0045] Embodiment 3: polyoxypropylene glycol 6000, polyoxypropylene trihydric alcohol 8000, polytetrahydrofuran glycol 3500;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

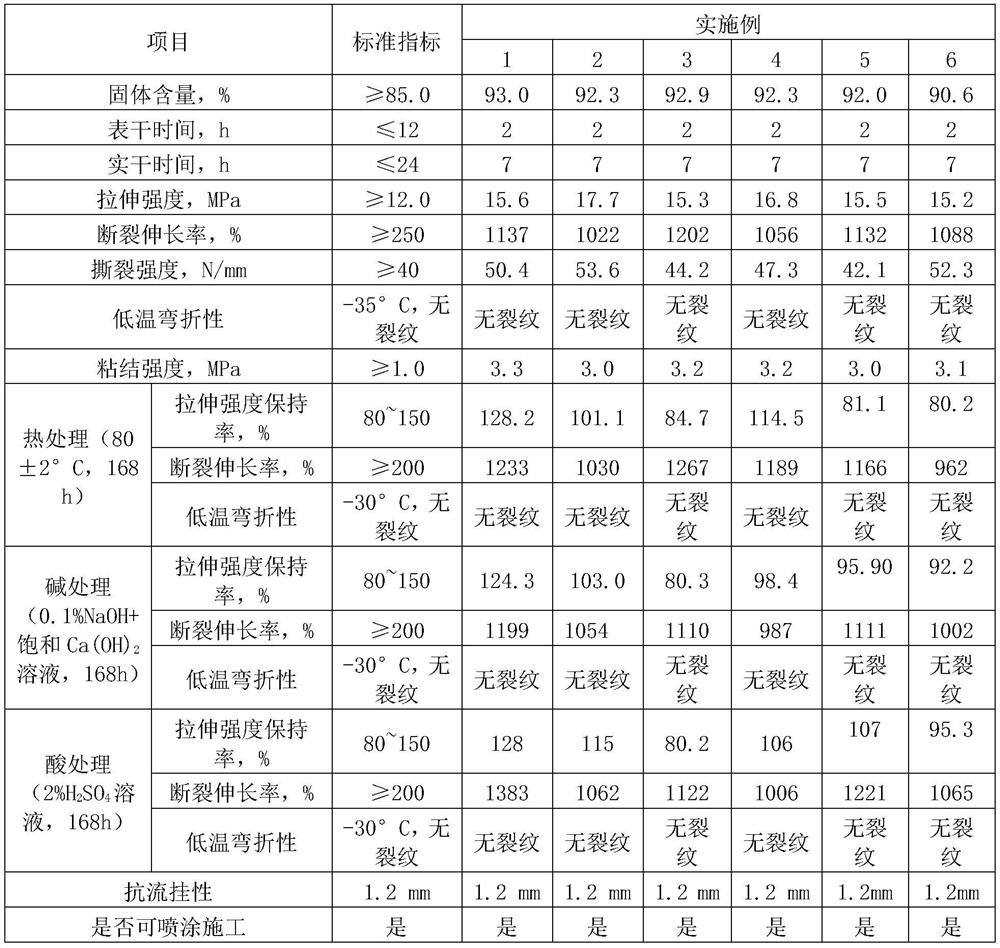

The invention discloses a spraying type polyurethane waterproof coating as well as a preparation method and a construction method thereof. The technical problem that a polyurethane waterproof coating in the prior art cannot have ultrahigh strength and ultrahigh toughness at the same time is solved. The polyurethane waterproof coating is prepared from the following raw materials in parts by weight: 136-170 parts of polyether polyol; 0 to 20 parts of polyester polyol; 34 to 65 parts of isocyanate; 15 to 25 parts of a solvent; 8.8 to 11 parts of pigment; 10 to 12 parts of filler; 1.5 to 3 parts of a chain extender; 0.8 to 1 part of a defoaming agent; 1.4 to 1.8 parts of a thixotropic agent; 0.4 to 0.6 part of a dispersing agent; and 0.15 to 0.35 part of a catalyst. The high-solid-content waterproof material has the characteristics of ultrahigh tensile strength, ultrahigh toughness and high solid content, is suitable for waterproofing of important projects such as railways, highways, bridges, tunnels, dams and the like, and is high in construction efficiency.

Description

technical field [0001] The invention relates to the technical field of waterproof coatings, in particular to a spray-coated polyurethane waterproof coating, a preparation method and a construction method thereof. Background technique [0002] With the development of science and technology, the research and development capabilities of waterproof coatings have been significantly improved. At present, the direction of key research and application is towards the development of waterproof materials with strong functionality and good environmental protection. Polyurethane waterproof coating has toughness, high strength, good adhesion, and excellent tear resistance. After drying and curing on the base layer, it can form a closed, continuous, seamless whole, improve the waterproof and impermeability of the base structure, and protect the base layer. It has strong adaptability to cracks and deformation, and can also slow down the aging and corrosion of the base material, thereby impr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C09D175/04C08G18/48C08G18/42C08G18/63E04G21/00E02D15/00E01D21/00

Inventor 丁玉乔张小强谢陶玲甄文战倪安斌王呼佳宋同伟宋南涛王颖王宝峰周明亮夏亮亮李雷刘勇

Owner 四川迈铁龙科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com