Method for quickly preparing super-hydrophobic surface on matrix based on 3D printing

A super-hydrophobic surface, 3D printing technology, applied in the field of 3D printing, can solve the problems of the difficulty of nano-level convex structure and the inability to achieve super-hydrophobicity on the surface of the substrate, and achieve the effect of saving raw materials, improving hydrophobic performance and good hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

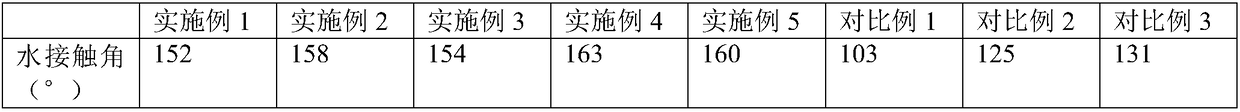

Examples

Embodiment 1

[0033] A method for rapidly preparing a superhydrophobic surface on a substrate based on 3D printing, characterized in that it comprises the following steps:

[0034] (1) Use drawing software to draw the surface of the geometric lattice array. The lattice array is composed of several convex points. The shape of the convex points is columnar. The shape of the lattice array is hexagonal. The distance between adjacent lattice arrays is 7 μm. , to obtain the two-dimensional geometric structure model diagram;

[0035] (2) Take a substrate, use ethanol to dissolve the surface liquid of the substrate to clean, dry naturally to obtain a clean and dry substrate surface, and then evenly coat one layer of adhesive on the surface of the plastic substrate as a base film;

[0036] (3) 50 parts of the printing raw material silicone-modified acrylic resin, 10 parts of silicon dioxide microparticles with a particle size of 0.8 μm, 5 parts of silicon dioxide nanoparticles with a particle size o...

Embodiment 2

[0043] A method for rapidly preparing a superhydrophobic surface on a substrate based on 3D printing, characterized in that it comprises the following steps:

[0044] (1) Use drawing software to draw the surface of the geometric lattice array. The lattice array is composed of several convex points. The shape of the convex points is a pillar shape. The shape of the lattice array is square, and the distance between adjacent lattice arrays is 10 μm. , to obtain the two-dimensional geometric structure model diagram;

[0045] (2) Take a substrate, use ethanol to dissolve the surface liquid of the substrate, and dry it naturally to obtain a clean and dry substrate surface, and then evenly coat a layer of adhesive on the surface of the metal substrate as a base film;

[0046] (3) 52 parts of the printing raw material silicone-modified acrylic resin, 15 parts of silica microparticles with a particle diameter of 5 μm, 8 parts of silica nanoparticles with a particle diameter of 200 nm, ...

Embodiment 3

[0053] A method for rapidly preparing a superhydrophobic surface on a substrate based on 3D printing, characterized in that it comprises the following steps:

[0054] (1) Use drawing software to draw the surface of the geometric lattice array. The lattice array is composed of several convex points. The shape of the convex points is spherical. The shape of the lattice array is a random lattice. The distance between adjacent lattice arrays is 20 μm, to obtain a two-dimensional geometric structure model diagram;

[0055] (2) Take a substrate, use ethanol water-soluble to clean the substrate surface liquid, dry naturally to obtain a clean and dry substrate surface, and then evenly coat one layer of adhesive on the coating substrate surface as a base film;

[0056] (3) 55 parts of the printing raw material silicone-modified acrylic resin, 20 parts of silica microparticles with a particle diameter of 8 μm, 10 parts of silica nanoparticles with a particle diameter of 300 nm and silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com