Composite multi-layer hydrophobic and anti-corrosion film as well as preparation method and application thereof

A technology of anti-corrosion film and composite layer, which is applied in the field of metal anti-corrosion, can solve problems that have not been reported, and achieve the effects of obvious effect, improved stability and improved anti-corrosion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

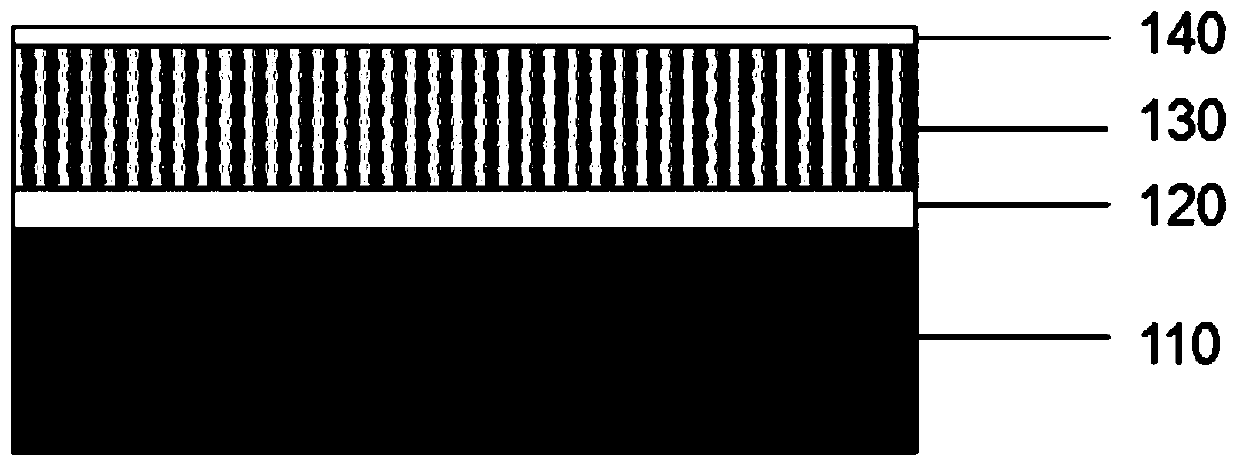

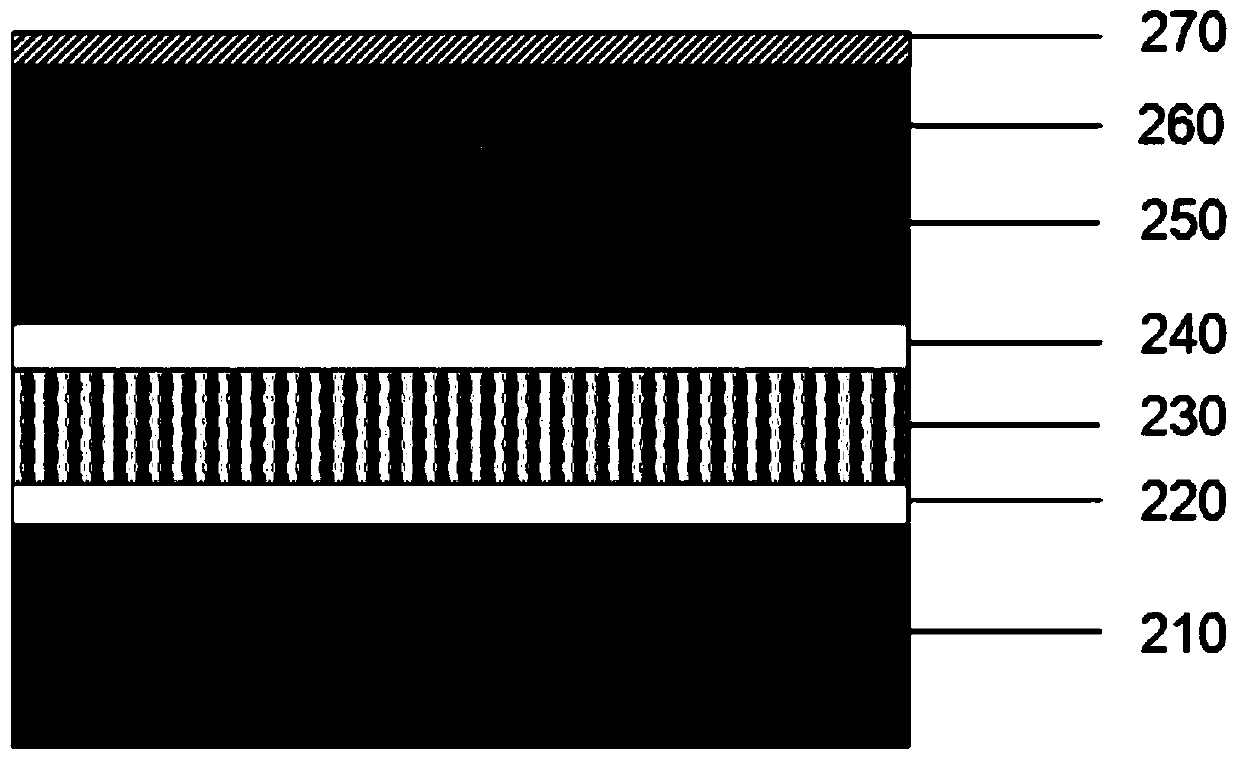

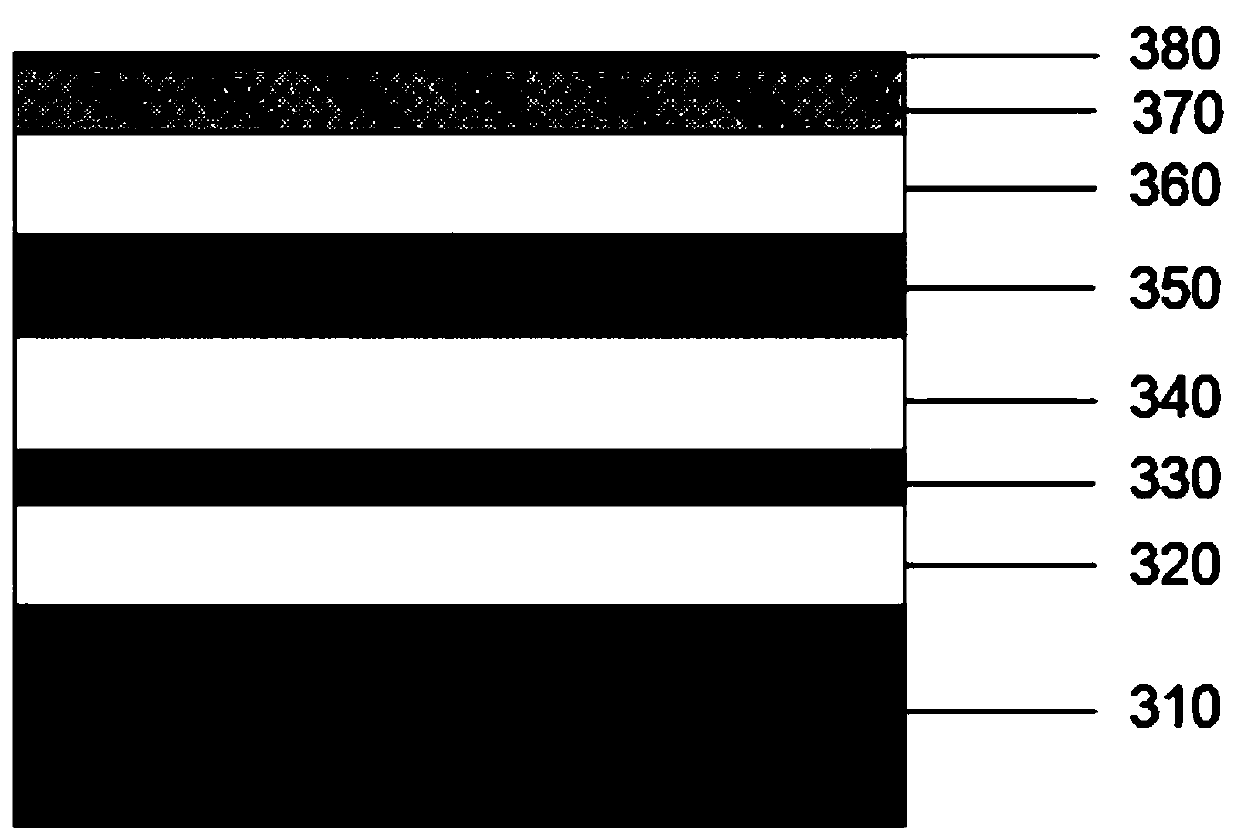

Method used

Image

Examples

Embodiment 1

[0027] A metal substrate covering the corrosion-resistant film of the present invention, wherein the metal substrate is stainless steel, and the preparation method comprises the following steps:

[0028] Pre-treatment steps: After cutting and scrubbing the stainless steel substrate, place it in acetone, absolute ethanol, and deionized water for ultrasonic cleaning and drying; then put the stainless steel substrate into the main chamber of the magnetron sputtering equipment, and wait for the vacuum up to 5×10 -4 After Pa, turn on the ion source for cleaning, the ion source power is 100W, and the stainless steel substrate is cleaned in an argon (Ar) atmosphere, and the chamber pressure is 2Pa.

[0029] Step 1: Carry out sputtering coating of chromium metal adhesion layer on the stainless steel substrate under the condition of argon atmosphere. Among them, the growth temperature of the sputter coating of the chromium metal adhesion layer is 25°C, the target power is 80W, the pre...

Embodiment 2

[0034] A metal substrate covering the corrosion-resistant film of the present invention, wherein the metal substrate is aluminum, and the preparation method comprises the following steps:

[0035] Pretreatment steps: After cutting and scrubbing the aluminum substrate, place it in acetone, absolute ethanol, and deionized water for ultrasonic cleaning and drying; then put the aluminum substrate into the main chamber of the magnetron sputtering equipment, and wait until the vacuum degree up to 5×10 -4 After Pa, turn on the ion source for cleaning, the ion source power is 500W, and the aluminum substrate is cleaned in an argon (Ar) atmosphere, and the chamber pressure is 5Pa.

[0036] Step 1: Under the condition of argon atmosphere, the sputter coating of the nickel metal adhesion layer is carried out on the aluminum substrate. The growth temperature of the sputter coating film of the nickel metal adhesion layer is 50°C, the target power is 150W, the pressure of the sputtering ch...

Embodiment 3

[0041] A metal substrate covering the corrosion-resistant film of the present invention, wherein the metal substrate is copper, and the preparation method comprises the following steps:

[0042] Pretreatment steps: After cutting and scrubbing the copper substrate, place it in acetone, absolute ethanol, and deionized water for ultrasonic cleaning and drying; then put the copper substrate into the main chamber of the magnetron sputtering equipment, and wait until the vacuum degree up to 5×10 -4 After Pa, turn on the bias cleaning, the bias voltage is -500V, and the copper substrate is cleaned in an argon (Ar) atmosphere, and the chamber pressure is 10Pa.

[0043] Step 1: Under the condition of argon atmosphere, the sputter coating of the nickel metal adhesion layer is carried out on the copper substrate. The growth temperature of the sputter coating of the nickel metal adhesion layer is 100°C, the target power is 200W, and the sputtering chamber The chamber pressure is 0.5Pa, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com