Dust discharging and collecting integrated device

A dust and driving device technology, which is applied in the direction of dust removal, loading/unloading, transportation and packaging, etc., can solve the problems of secondary dust overflow, increase the specific gravity of materials, and high energy consumption in operation, so as to reduce secondary dust and reduce secondary dust. Less dust, no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

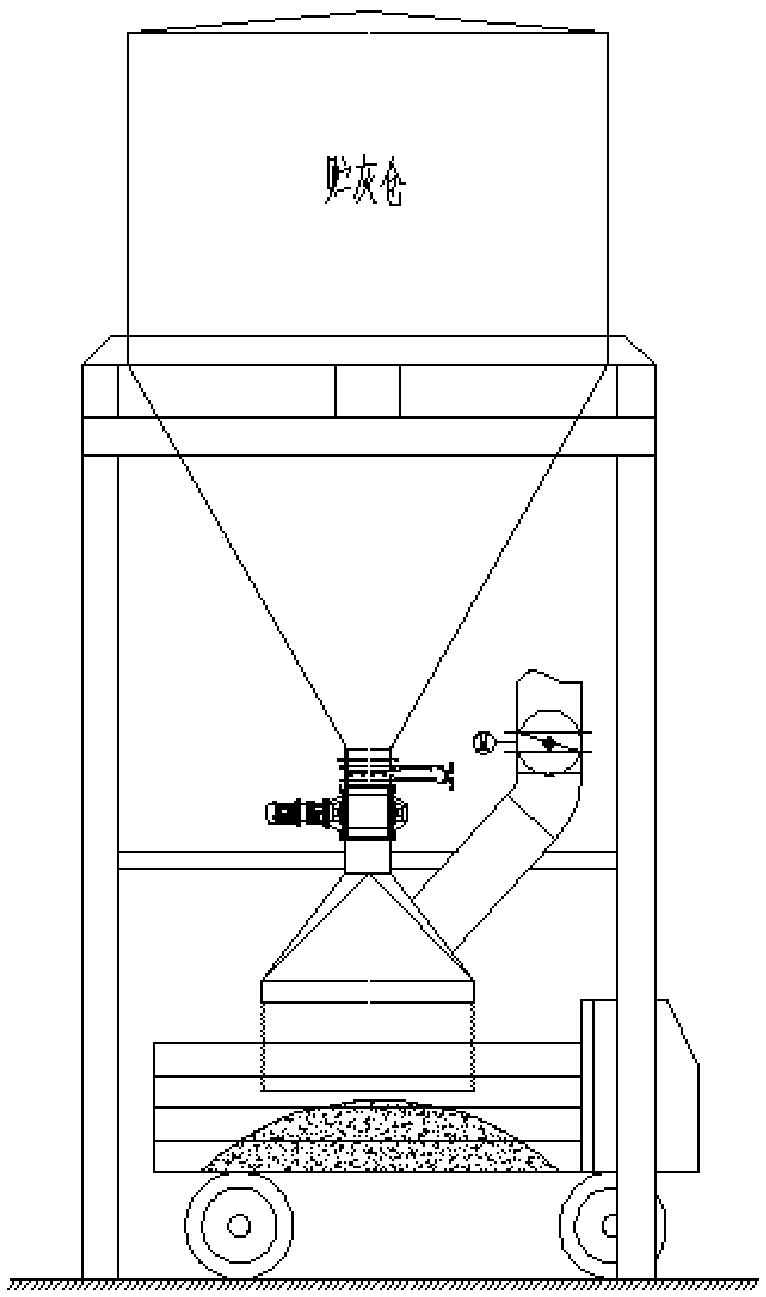

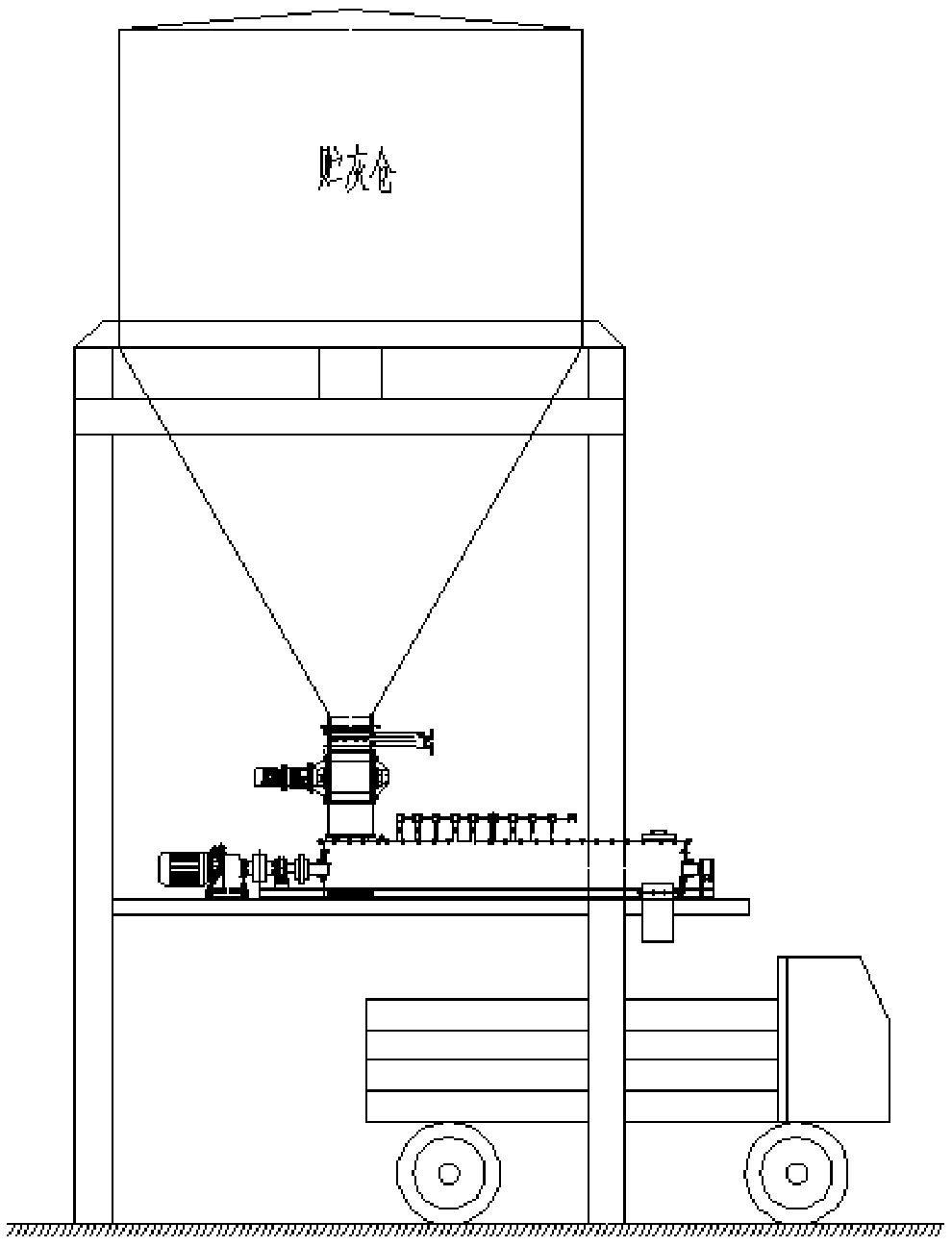

[0034] According to incomplete statistics, only the first type ( figure 1 ) And the second ( figure 2 ) The number of ash storage bins for ash unloading is more than 50. If this technical improvement can be widely used, it will not only have greater economic benefits, but also greater social benefits.

[0035] 1. Direct economic benefits:

[0036] Based on the improvement of the ash unloading process of the ash storage silo #1, 2, 3, and 4 in the vanadium extraction process optimization project of a plant in Panzhihua Iron and Steel, the cost of each technical improvement is 174,300,000 yuan, and the product profit is 15% calculated: 50×17.433×15 % = 1.30.75 million yuan;

[0037] 2. Indirect economic benefits: (Estimating that the ash storage silo discharges ash 300 times a year, and each time the ash discharge is 0.5 hours, then the annual ash discharge time is 150 hours)

[0038] Compared with the first ash unloading process (calculated based on only one ash storage bin operating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com