Two-dimensional anode dust collection electric precipitator

An electrostatic precipitator and anode technology, applied in the field of two-dimensional anode dust collection electrostatic precipitator, can solve the problems of low cathode line discharge voltage and small dust collection area, achieve strong corona intensity, large dust collection area, and increase anode The effect of dust collection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

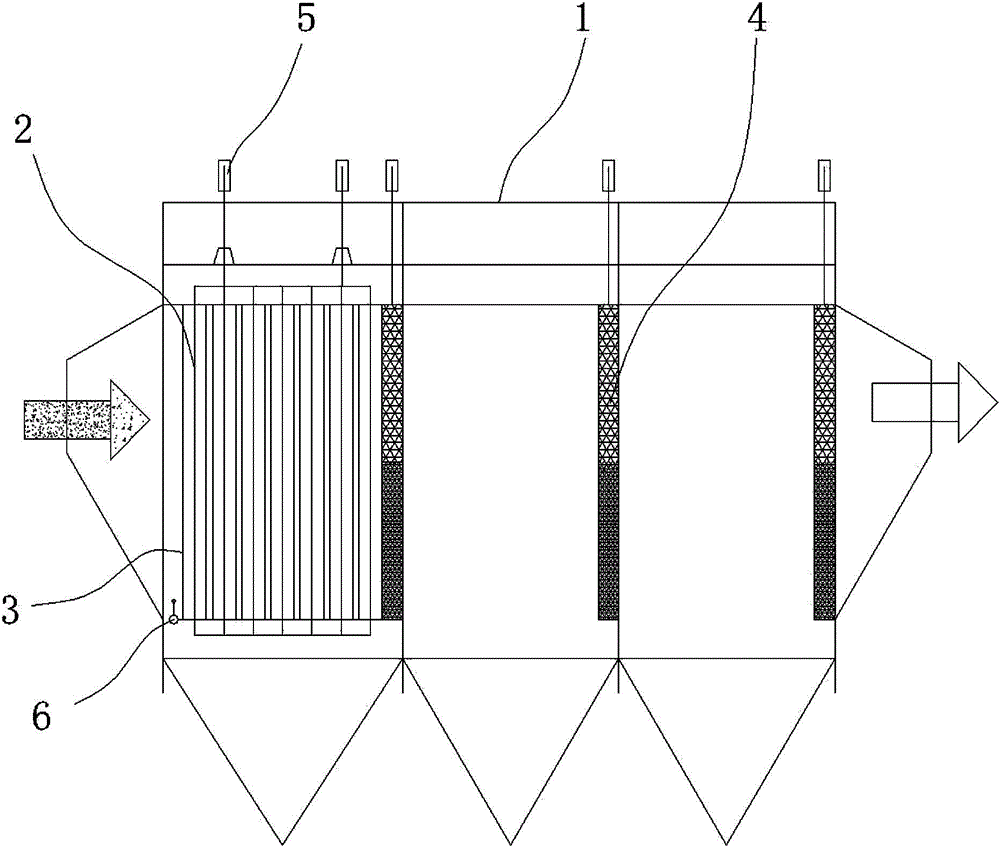

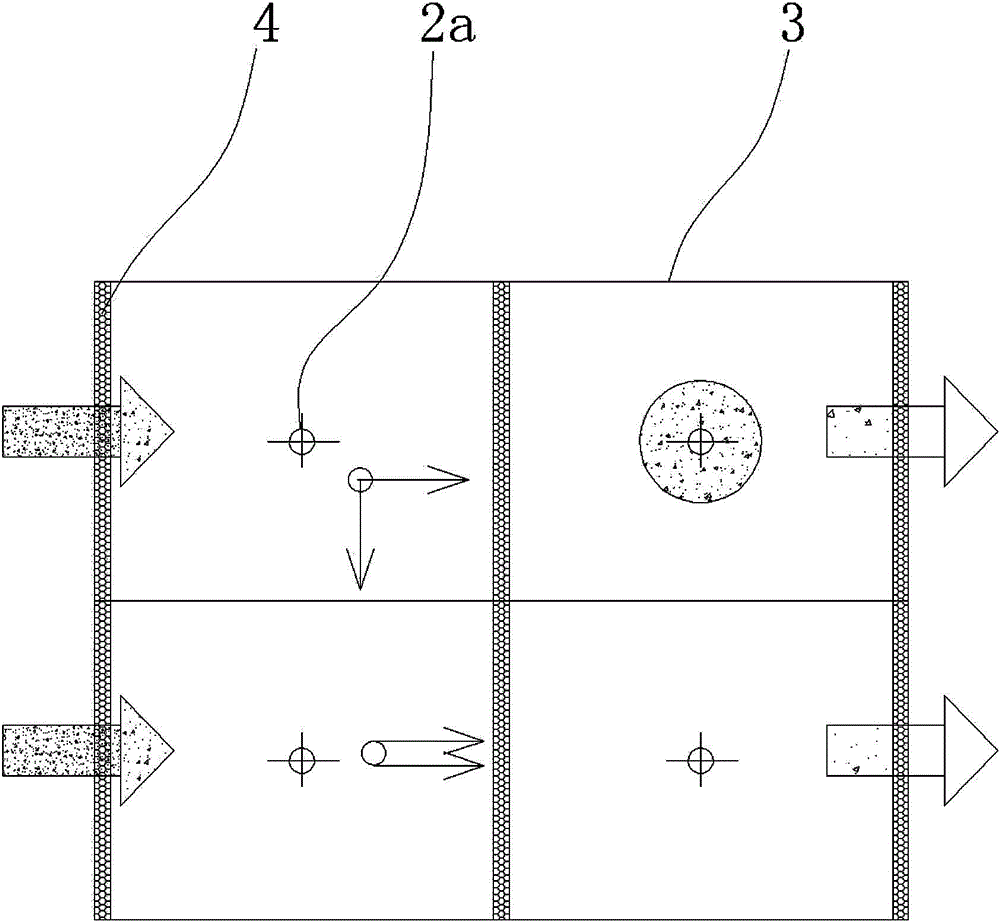

[0025] Example 1: Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 6 As shown, the two-dimensional anode dust-collecting electric precipitator provided by the present invention includes a flue gas channel 1, and discharge cathode lines 2 and horizontal dust-collecting anode plates 3 are alternately arranged in the electric field area of the flue gas channel 1, and the horizontal dust-collecting The anode plate 3 is a traditional electrostatic precipitator structure, which can be C480 type, W type, Z type or other forms. The arrangement is parallel to the airflow direction and perpendicular to the direction of the electric field force. The horizontal dust collection anode plate 3 forms an anode row, and a group of anode rows in the vertical airflow direction forms a row, and there is a gap between every two adjacent anode rows parallel to the airflow direction, and each row of anodes There is a gap between the rows, and the gap between each anode row is 3...

Embodiment 2

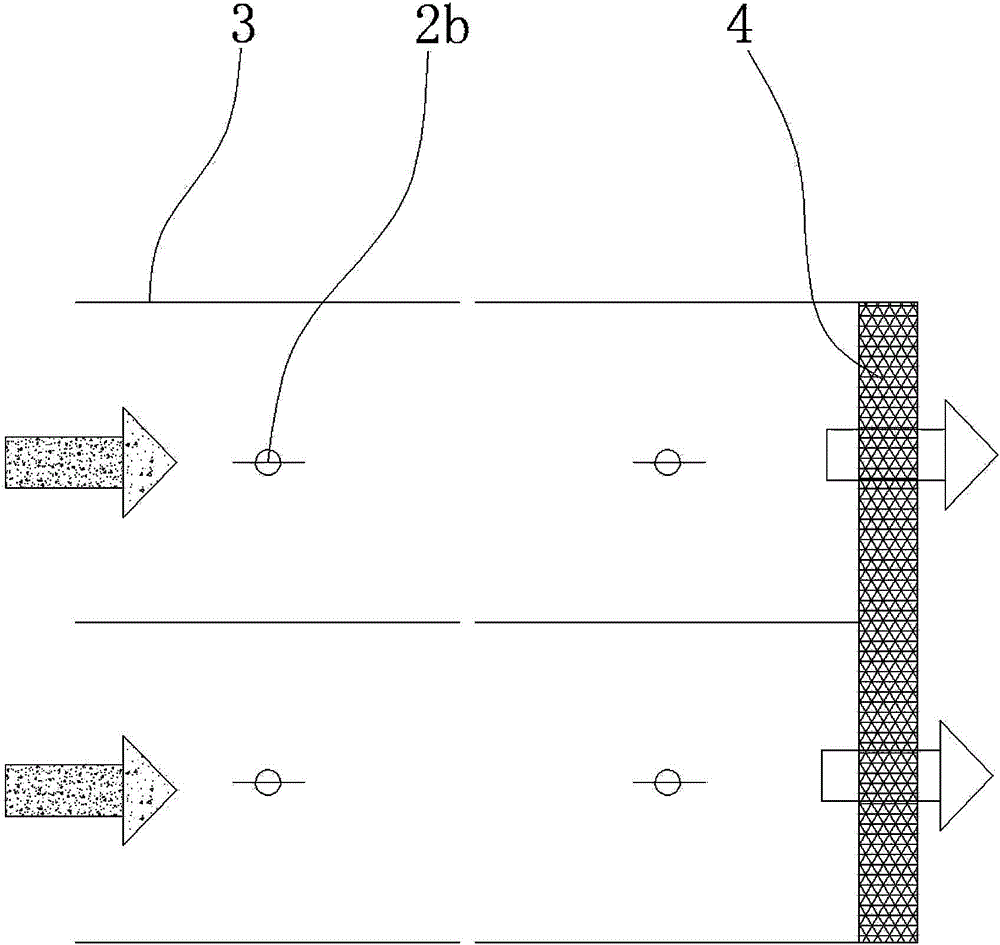

[0030] Example 2: Such as Figure 6 As shown, there is also a gap between every two adjacent anode rows parallel to the airflow direction as described in the above-mentioned embodiment 1, that is, in each row of the anode rows, the adjacent two rows of horizontal dust collection Gaps are provided between the anode plates 3, and the gaps between two adjacent rows of horizontal dust-collecting anode plates 3 in each row of anode rows are connected. The cooperating and fixed vertical dust-collecting anode plate 4 in the corresponding through gap at the rear is the second vertical dust-collecting anode plate 4b, and the second vertical dust-collecting anode plate 4b has a single-layer orifice structure.

[0031]Dust suppression process: the four-way discharge cathode line 2a is a high-voltage discharge, which releases free electrons while ionizing the flue gas. The dust in the corona area is mainly charged with positive charges, and the dust outside the corona area is mainly cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com