Dust removal method for electric purification part and air purifier with electric purification part

A technology of electric purification and components, applied in the direction of electrode cleaning, heating method, electrode structure, etc., can solve the problems of low safety factor, easy damage of dust collection, poor cleaning effect, etc., to prolong service life, reduce frequency, improve The effect of life convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The electric purification component provided in this embodiment includes a charging part and a dust collecting part, and the dust collecting part includes a dust collecting electrode; the dust collecting electrode includes a dust collecting electrode body and is respectively arranged on two surfaces of the dust collecting electrode body The porous layer on the surface, the porous layer in this embodiment is formed by spraying carbon powder on the surface of the aluminum plate, the thickness of the porous layer is 8 μm, the porosity of the porous layer is 80%, and the specific surface area of the dust collecting electrode is 850m 2 / g.

[0064] The electric purification unit in this embodiment also includes a dust removal unit, a dust removal controller, a detector, and an ash receiving unit, wherein: the dust removal unit interferes with the dust collecting electrode during operation; To control the work of the cleaning part; the detector is arranged in the charging p...

Embodiment 2

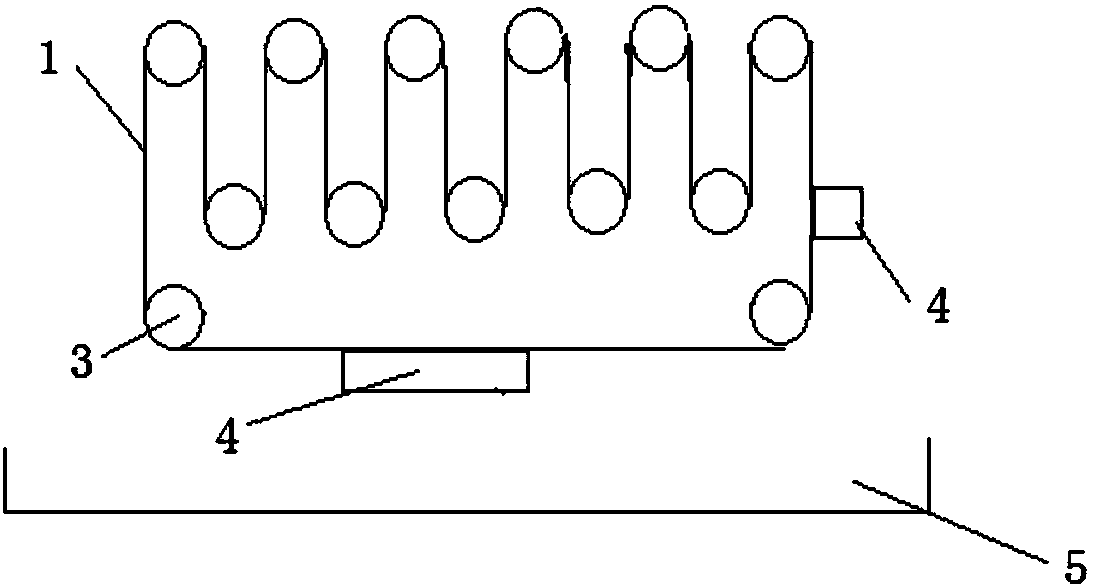

[0069] The electric purification component provided in this embodiment includes a charging part and a dust collecting part, the dust collecting part includes a dust collecting electrode; the dust collecting electrode includes a dust collecting electrode body and a porous hole arranged on the surface of the dust collecting electrode body layer, such as figure 2 As shown, the material of the dust-collecting electrode body is a flexible conductive material, and the dust-collecting electrode body is ring-shaped end-to-end. The electric purification component also includes a transmission mechanism for driving the dust-collecting electrode body to rotate. The transmission mechanism in this embodiment is specifically a plurality of rotating shafts 3, and the dust collecting electrode body is sleeved on each of the rotating shafts. As a variable embodiment, the transmission mechanism may also be a gear in other embodiments.

[0070] goodbye figure 2 , the electric purification unit...

Embodiment 3

[0074] The structure and connection relationship of the charging part, dust collecting part, transmission mechanism, ash cleaning part, ash cleaning controller and ash receiving part in the electric purification part provided by this embodiment are all the same as that of embodiment 2, the difference is that: In this embodiment, a particle concentration sensor is used to replace the timer in embodiment 2. There are two particle concentration sensors, which are respectively arranged at the inlet and outlet of the electric purification component, and they are all connected to the cleaning controller; and The prompter in this embodiment is connected with the ash receiving part, and is used for sending out a reminder to clean the ash receiving part when the content weight of the ash receiving part reaches a preset value.

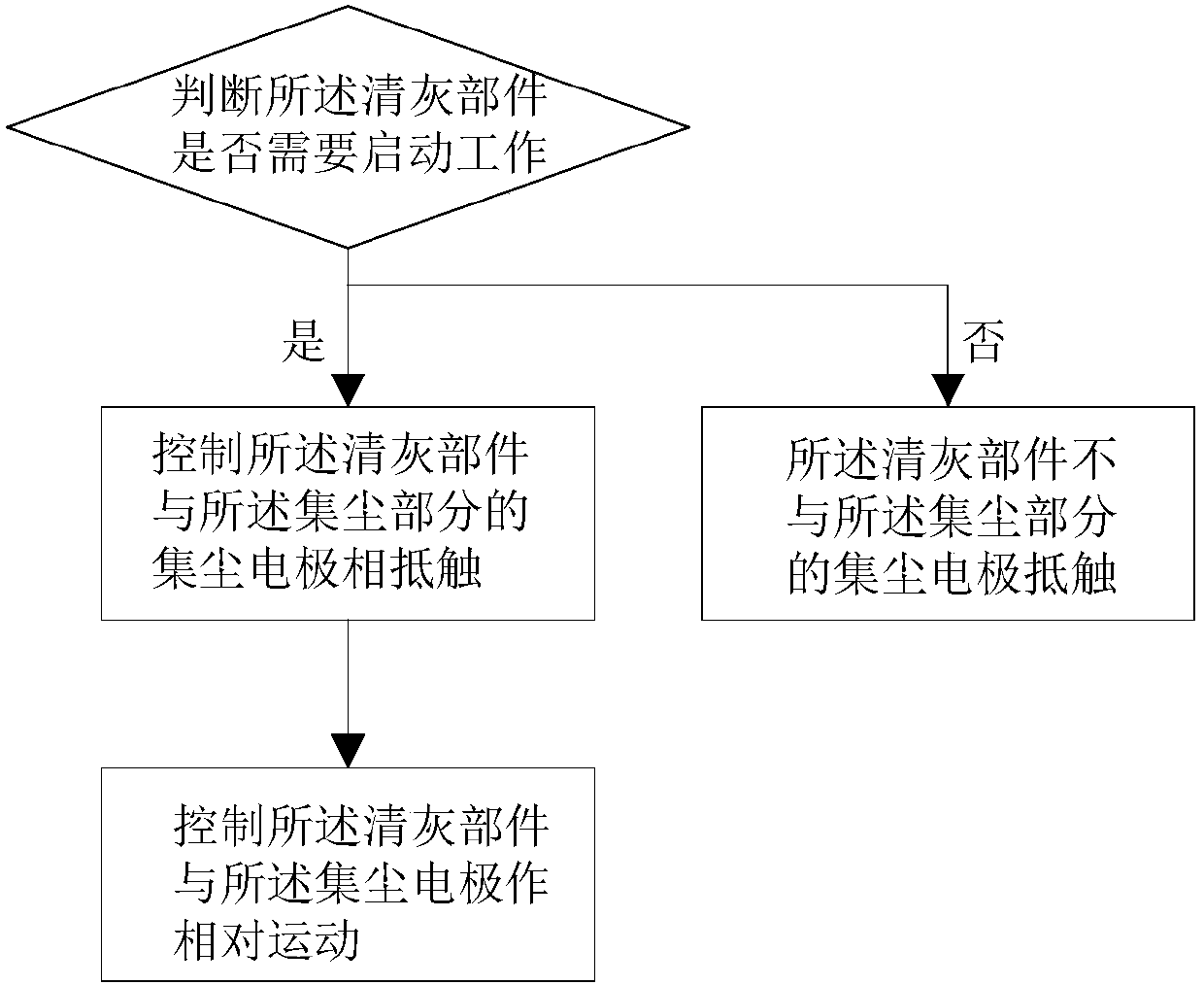

[0075] Such as figure 1 As shown, the dust cleaning method of the above-mentioned electric purification unit in this embodiment includes: judging whether the du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com