Reverse blowing system of road sweeper and road sweeper

A technology of back blowing and road sweeper, applied in the field of sanitation machinery, can solve the problems of insufficient back blowing, noise, inconvenience for operators, etc., and achieve the effect of reducing secondary dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

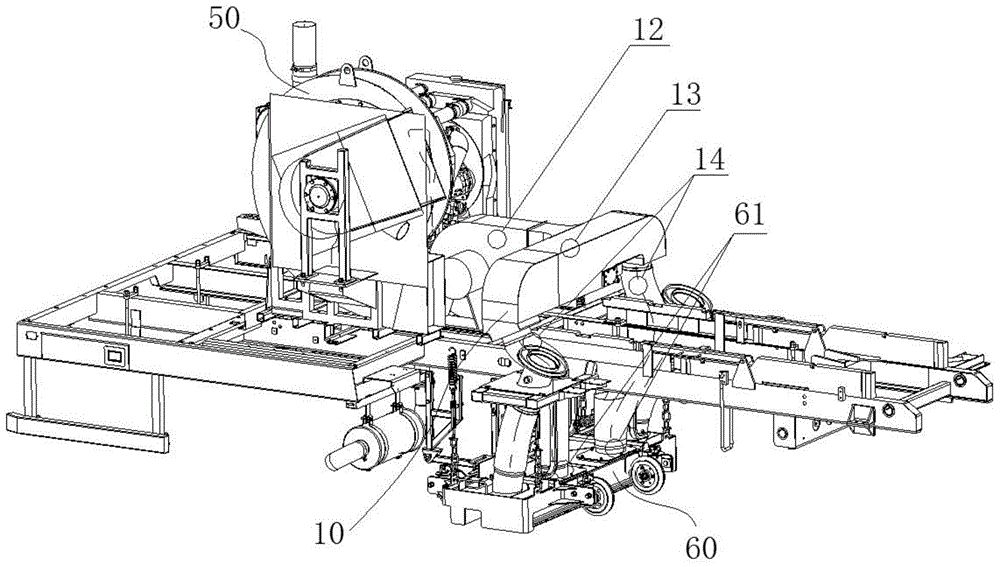

[0035] figure 1 It is a structural schematic diagram of the blowback system of the road sweeper according to the first embodiment of the present invention.

[0036] like figure 1 As shown, the blowback system 10 of the road sweeper of the first embodiment includes a blowback fan and a flow path for blowback.

[0037] The inlet of the reverse blowing fan is connected with the atmosphere, and the outlet of the reverse blowing blower is connected with the inlet of the reverse blowing flow path. In the first embodiment, the reverse blowing fan is a reverse blowing centrifugal fan 12, and the reverse blowing centrifugal fan 12 and the cleaning centrifugal fan 50 are independent of each other. The reverse blowing centrifugal fan 12 and the cleaning centrifugal fan 50 are all arranged on the chassis of the road sweeper. The reverse blowing centrifugal fan 12 is installed in the middle part of the chassis of the road sweeper.

[0038] The reverse blowing centrifugal blower 12 purp...

no. 2 example

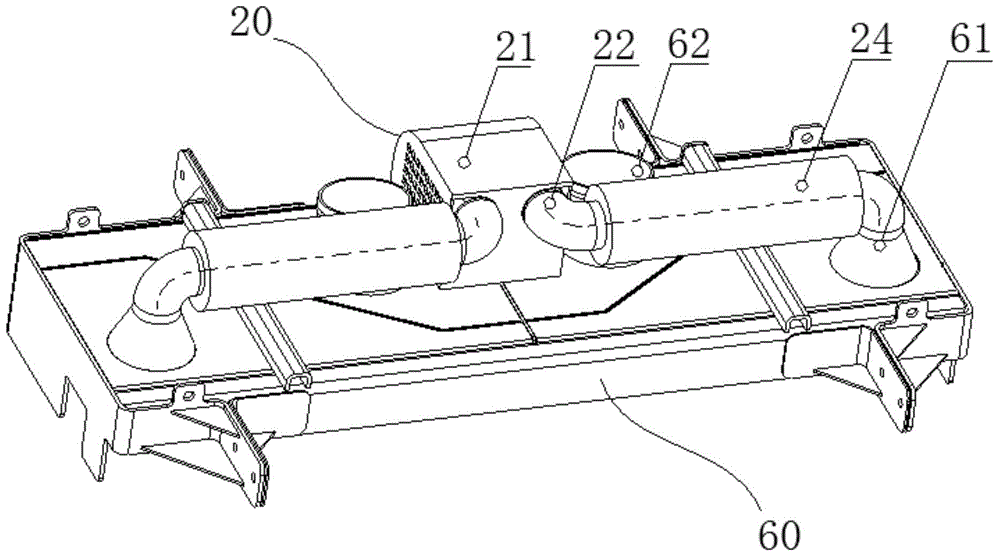

[0046] figure 2 It is a structural schematic diagram of the blowback system of the road sweeper according to the second embodiment of the present invention.

[0047] like figure 2 As shown, the blowback system 20 of the road sweeper of the second embodiment includes a blowback blower, a blowback flow path and a noise reduction protective cover 21 .

[0048] In the second embodiment, the reverse blowing fan is a reverse blowing centrifugal fan, and the reverse blowing centrifugal fan and the cleaning centrifugal fan are independent of each other. The reverse blowing centrifugal fan is arranged in the middle of the top surface of the suction cup 60 and between the two suction ports 62 of the suction cup 60 for connecting to the dustbin. Dust and sundries are sucked into the dustbin from two suction ports 62 of the suction cup 60. Noise elimination protective cover 21 covers are located at the outside of reverse blowing centrifugal fan, therefore in figure 2 The reverse bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com