Electrostatic-bag composite dust-collector

A technology of electric bag compounding and dust collector, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of not being able to significantly reduce the resistance of filter bags, not being able to improve various defects, and dust being too late to charge, etc. Achieve the effect of reducing equipment maintenance cost, improving cleaning efficiency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

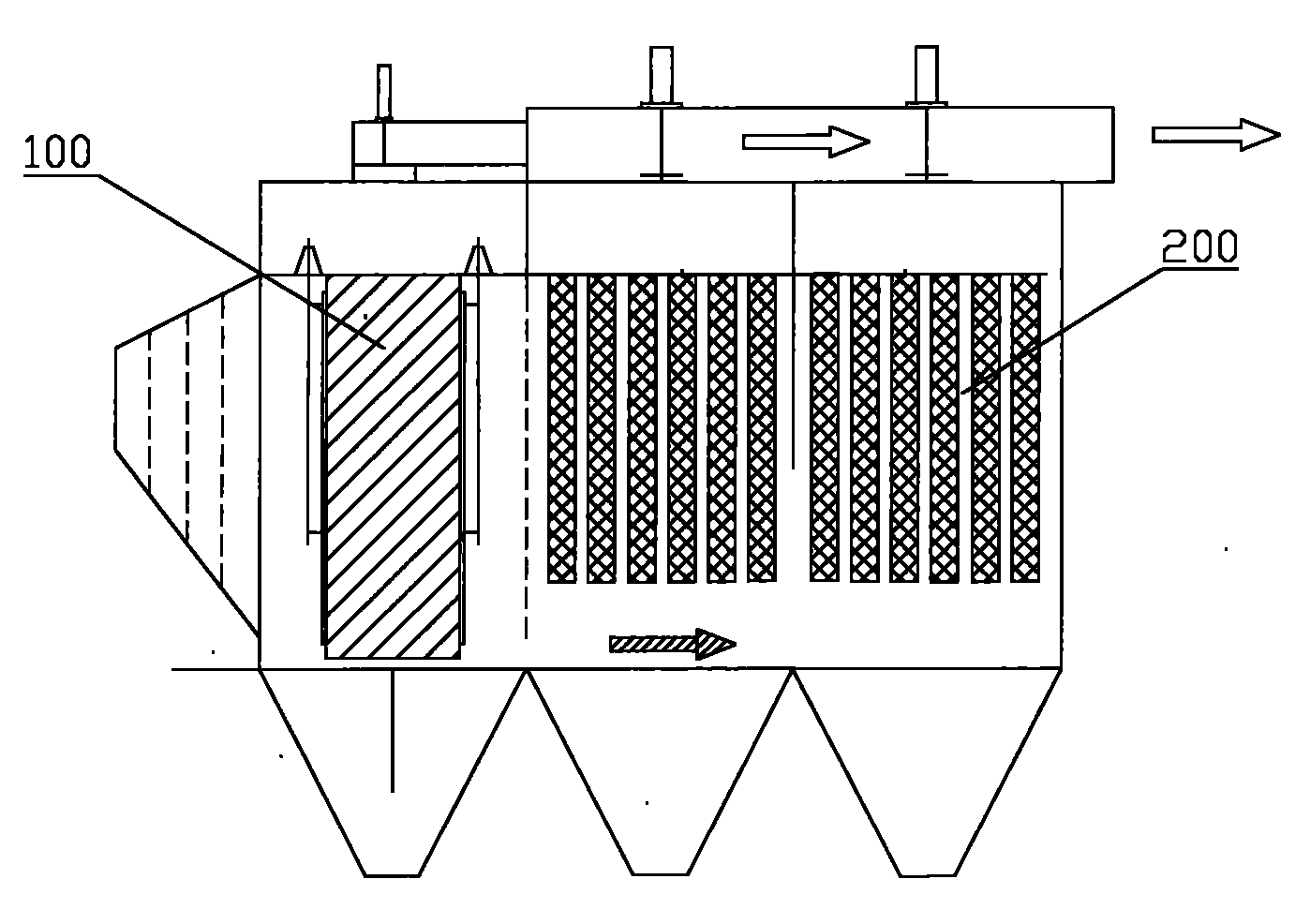

[0034] The core of the present invention is to provide an electric bag composite dust collector, which can not only effectively improve the dust removal efficiency, but also significantly improve the charging rate of the dust before passing through the filter bag, and greatly reduce the time when the dust passes through the filter bag. The resistance, which effectively prolongs the service life of the filter bag and reduces the cost of dust removal.

[0035] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

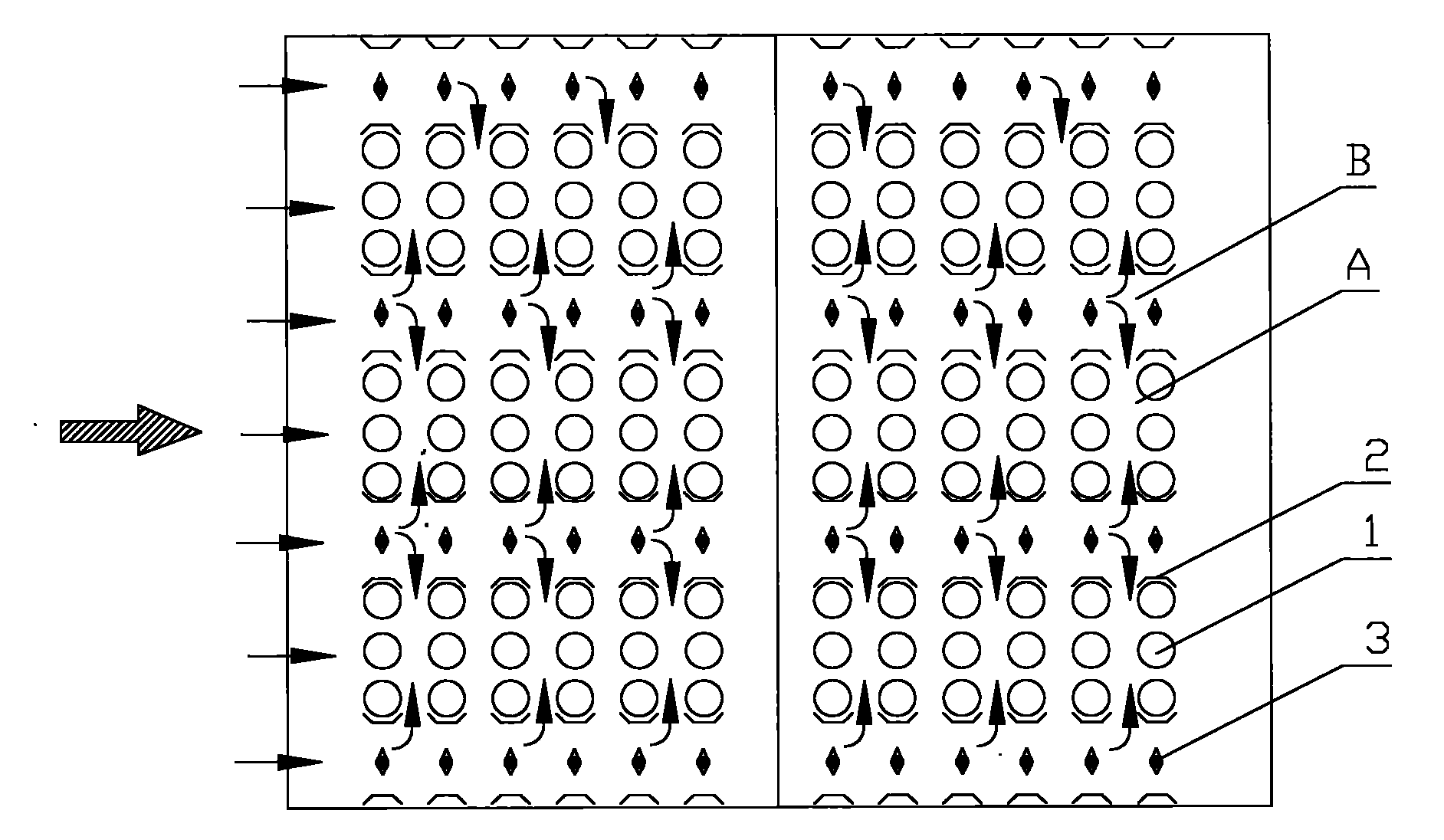

[0036] Please refer to figure 2 , figure 2 It is a top view of a specific embodiment of the electric pocket mixing zone provided by the present invention.

[0037]As shown in the figure, the direction indicated by the arrow in the figure is the flow direction of the flue gas in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com