Diatomite-based low-cost ecological environment-friendly type flat ceramic membrane and preparation method thereof

A low-cost, ceramic membrane technology, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve the problems of poor mechanical strength of filter membranes, frequent fouling of components, and inability to acid and alkali cleaning. Industrial prospects, the effect of low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of ceramic flat membrane support

[0027] Take 500-mesh food-grade diatomaceous earth through a 100-mesh sieve and remove the upper layer of hydraulic sedimentation and dry the resulting powder 50Kg, add CMC3Kg, starch 3Kg, zeolite 2.5Kg, D50 0.5 micron alumina powder 1Kg, mix in the double cone Mix the material in the feeder for 30 minutes, take 3.2Kg of hot water and add 3Kg of PEG1Kg tung oil, stir and disperse evenly, add 7.28Kg of nano titanium dioxide dispersion with 30% solid content and 3.35Kg of nano silica sol with 30% solid content, stir After 4 hours, add it to the mixed powder in the kneader in the form of spray, knead the mud, extrude and shape, dry and sinter at 1100 degrees, keep for 4 hours to obtain diatomaceous earth with an average pore size of 1.2 microns and a porosity of 43.3% Ceramic flat membrane support.

[0028] (2) Preparation of separation membrane

[0029] Prepare 10Kg of spherical alumina suspension with a median particle size o...

Embodiment 2

[0031] (1) Preparation of ceramic flat membrane support

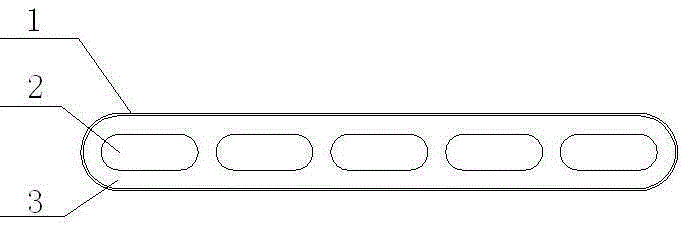

[0032] Take 325-mesh food-grade diatomaceous earth through a 100-mesh sieve and remove the upper layer of hydraulic sedimentation and dry 50Kg. Add HPMC4Kg, starch 5Kg, zeolite 1.5Kg, D50 is 1 micron alumina powder 1.5Kg, in the double cone Mix the materials in the mixer for 30 minutes, take 2.5Kg of hot water and add 3Kg of PEG3Kg tung oil, stir and disperse evenly, add 3.35Kg of nano-titania dispersion with 30% solid content and 8.3Kg of nano-silica sol with 30% solid content. After stirring for 4 hours, add it to the powder mixed in the kneader in the form of spray. figure 1 The shape is extruded, dried and sintered at 1250 degrees, and kept for 4 hours to obtain a diatomite ceramic flat membrane support with an average pore diameter of 3.36 microns and a porosity of 49.5%.

[0033] (2) Preparation of separation membrane

[0034] Prepare 10Kg of spherical alumina suspension with a median particle size of 0.6 microns with a...

Embodiment 3

[0036] (1) Preparation of ceramic flat membrane support

[0037] Take 200-mesh food-grade diatomaceous earth through a 100-mesh sieve and remove the upper layer of hydraulic sedimentation and dry 50Kg. Add HPMC2Kg, PVA3Kg, starch 6Kg, zeolite 10Kg, D50 is 1 micron alumina powder 4Kg, in the double cone Mix the materials in the mixer for 30 minutes, take 1Kg of hot water and add 1.5Kg of PEG3Kg tung oil, stir and disperse evenly, add 5.5Kg of nanometer titanium dioxide dispersion with a solid content of 30% and 8.3Kg of nanosilica sol with a solid content of 30%. After stirring for 4 hours, add it to the powder mixed in the kneader in the form of spray. figure 1 The shape is extruded, dried and sintered at 1300 degrees, and kept for 4 hours to obtain a diatomite ceramic flat membrane support with an average pore diameter of 5.5 microns and a porosity of 51.4%.

[0038] (2) Preparation of separation membrane

[0039] Prepare 10Kg of spherical alumina suspension with a median particle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com