Double-barrel inner turbine central cylinder of cyclone separator

The technology of a cyclone separator and an inner turbine is applied in the direction of the cyclone axial reversal device, the cyclone device, etc., which can solve the problem of low separation efficiency, achieve high separation efficiency, reduce choked flow and secondary eddy current. , the effect of low running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

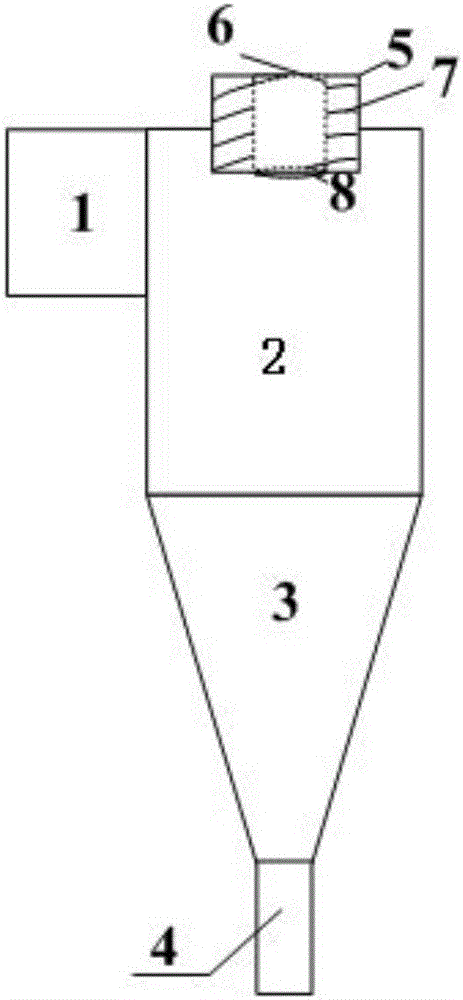

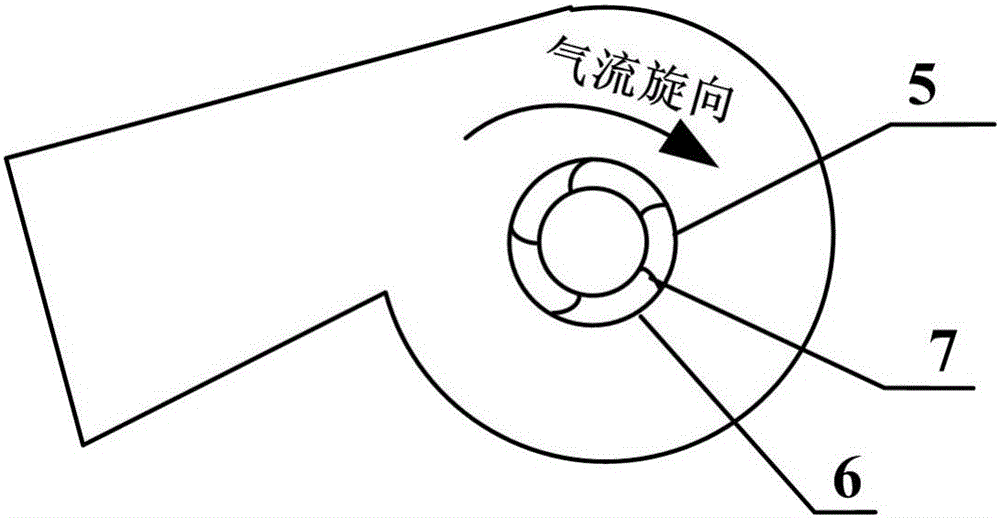

[0030] A new 480t / h circulating fluidized bed boiler, see Figure 1 to Figure 7 , The central cylinder of the two cyclone separators of the boiler adopts a double-tube inner turbine central cylinder. The separator cylinder 2 is respectively connected with the inlet flue 1 and the separator cone 3, the separator standpipe 4 is arranged at the lower part of the separator cone 3, the center cylinder outer cylinder 5 is inserted into the separator cylinder 2 from the upper part, and the center The top of the outer cylinder 5 is fixed in a free hanging manner, and is freely matched with the separator cylinder 2, and can slide relative to each other in a hot state without an expansion dead point.

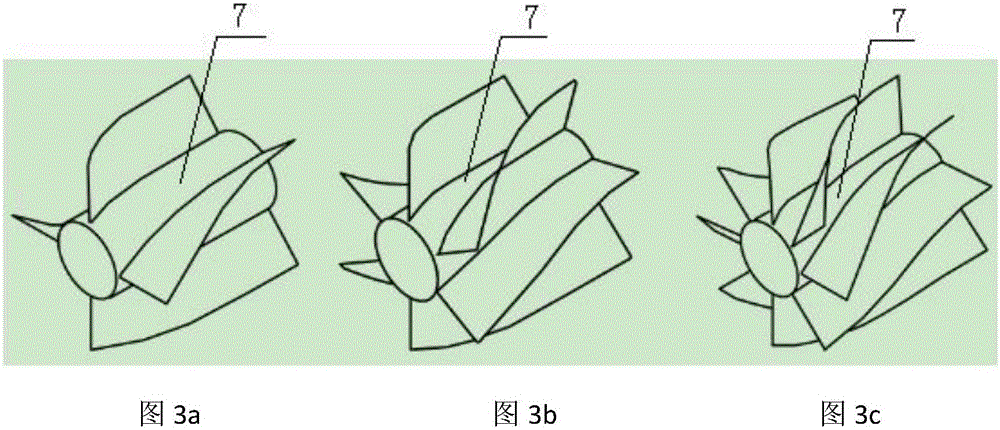

[0031] In order to improve the separation efficiency, the turbine 7 inside the central cylinder outer cylinder 5 and the central cylinder inner cylinder 6 adopts 4 blades. The depth of the center cylinder outer cylinder 5 inserted into the separator is 10% of the height of the separator ...

specific Embodiment approach 2

[0034] For a 240t / h circulating fluidized bed boiler in service, the central cylinder of the two cyclone separators of the boiler adopts a conventional design. During operation, the carrying capacity is insufficient, and the insertion depth of the original central cylinder is 30% of the height of the separator cylinder 2, and its diameter is 40% of the diameter of the separator cylinder 2.

[0035] The central cylinder of the boiler cyclone separator has been replaced and modified by adopting the double-cylinder internal turbine central cylinder method. The depth of the center cylinder outer cylinder 5 inserted into the separator is 12% of the height of the separator cylinder 2, and the diameter of the central cylinder outer cylinder 5 is the separator. 50% of the diameter of the cylinder body 2, the top of the central cylinder outer cylinder 5 is fixed in a free hanging manner.

[0036] Through the above-mentioned transformation, the boiler can realize full-load operation, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com