Power cyclone separator

A cyclone and power technology, which is applied in the direction of cyclone devices and devices whose axial direction of cyclone can be reversed, etc., can solve the problem of low dust removal efficiency of fine dust and small density dust, inability to handle viscous dust, and unsatisfactory separation efficiency. and other problems, to achieve the effect of reasonable pressure loss, overcoming radial motion, and reducing the chance of secondary dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

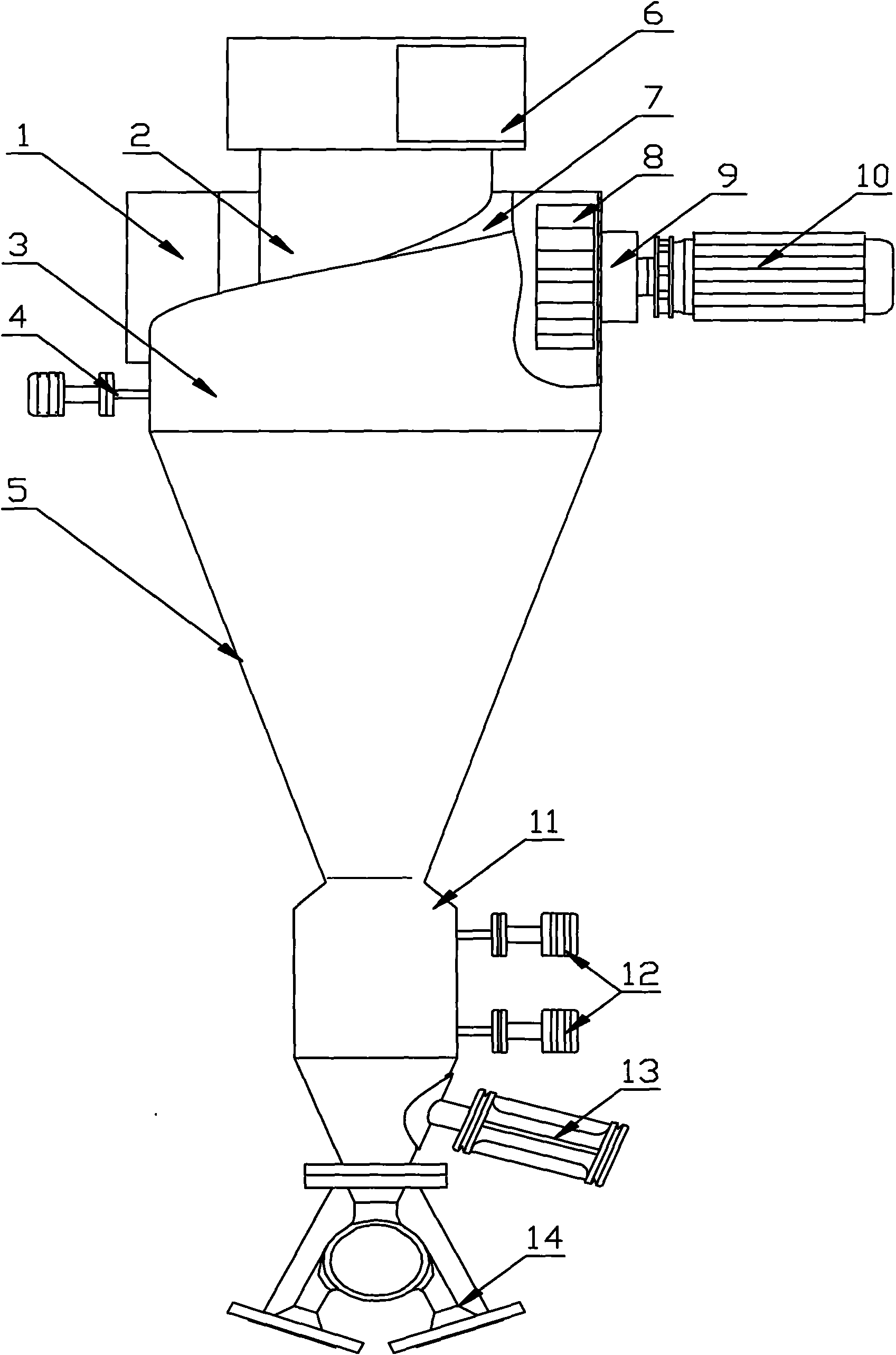

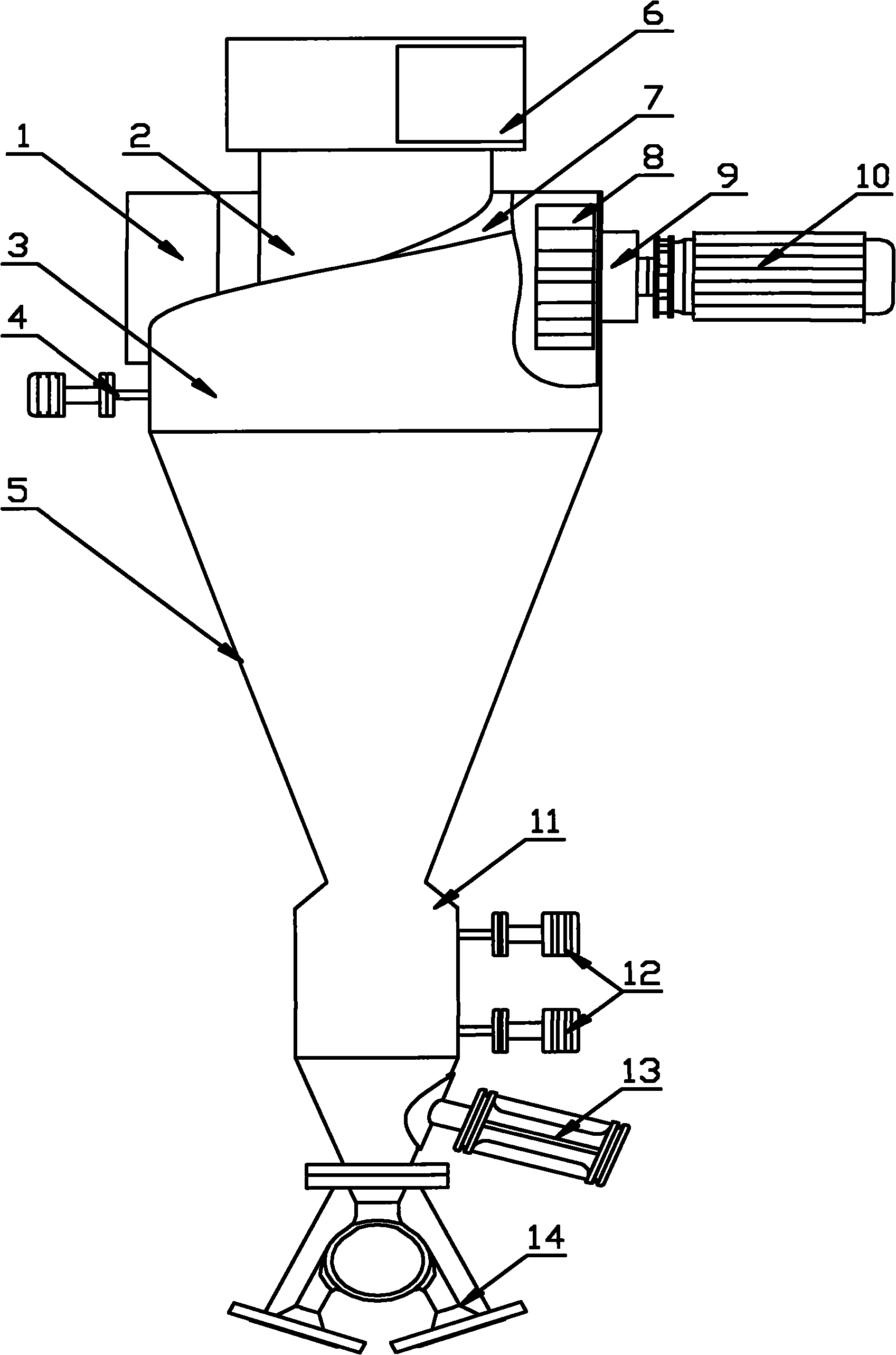

[0009] Such as figure 1 As shown, the power cyclone of the present invention includes a cylinder 3, a cone 5, an ash collecting hopper 11 and a discharge valve 14, etc., the lower section of the cylinder 3 is connected with the cone 5, and the upper section of the cylinder 3 is a spiral The guide plate 7, the cylinder body 3 are provided with a purified gas outlet 6 and an air inlet 1 in a tangential direction relative to the cylinder body 3, and the air inlet 1 and the purified gas outlet 6 are connected through the exhaust pipe 2 inside the cylinder body; A flow rate transmitter 4 is installed on one side of the air inlet 1, and a variable-frequency speed-regulating motor 10 is installed on the opposite side of the air-inlet 1. The page-turning mechanism 8 is connected; the helix angle of the cone 5 adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com