Dust collection polar plate based on particle trap effect, novel polarity form and efficient electrostatic dust collector

A technology of electrostatic precipitator and dust collecting plate, which is applied in the field of electrostatic precipitator and environmental protection, can solve the problems of weakening electrode discharge characteristics and anti-corona, so as to reduce the decline of collection efficiency, reduce the drag force, and suppress the anti-corona effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

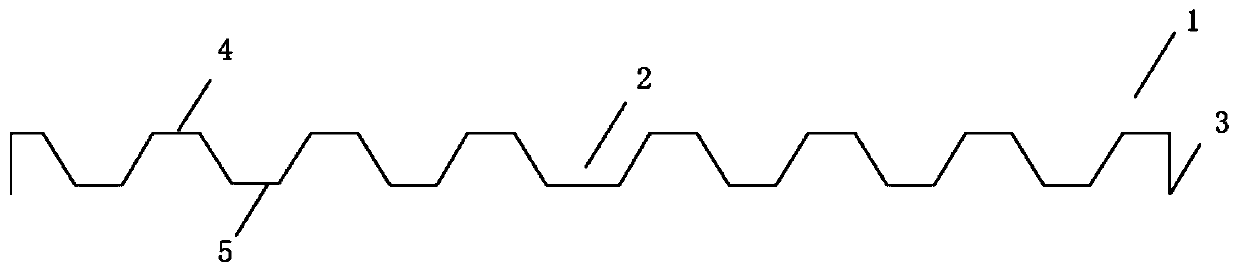

[0071] combined with figure 1 As shown, this embodiment relates to a dust collection plate 1 based on the particle trap effect, the dust collection plate 1 forms a plurality of raised folded plates 4 and grooves 5 arranged at intervals by bending, and the grooves 5 Particle traps are formed. The cross section of the groove 5 is an isosceles trapezoid, the width of the upper bottom surface of the cross section is 3-11cm, the width of the lower bottom surface is 2-6cm, the depth of the groove 5 is 1-5cm, and the angle between the two waists of the groove 5 and the bottom surface of the groove 5 is 100-135°. The dust-collecting pole plate 1 is also provided with reinforced folded plates 3 , and the strengthened folded plates 3 are arranged at both ends of the dust-collected pole plate 1 .

Embodiment 2

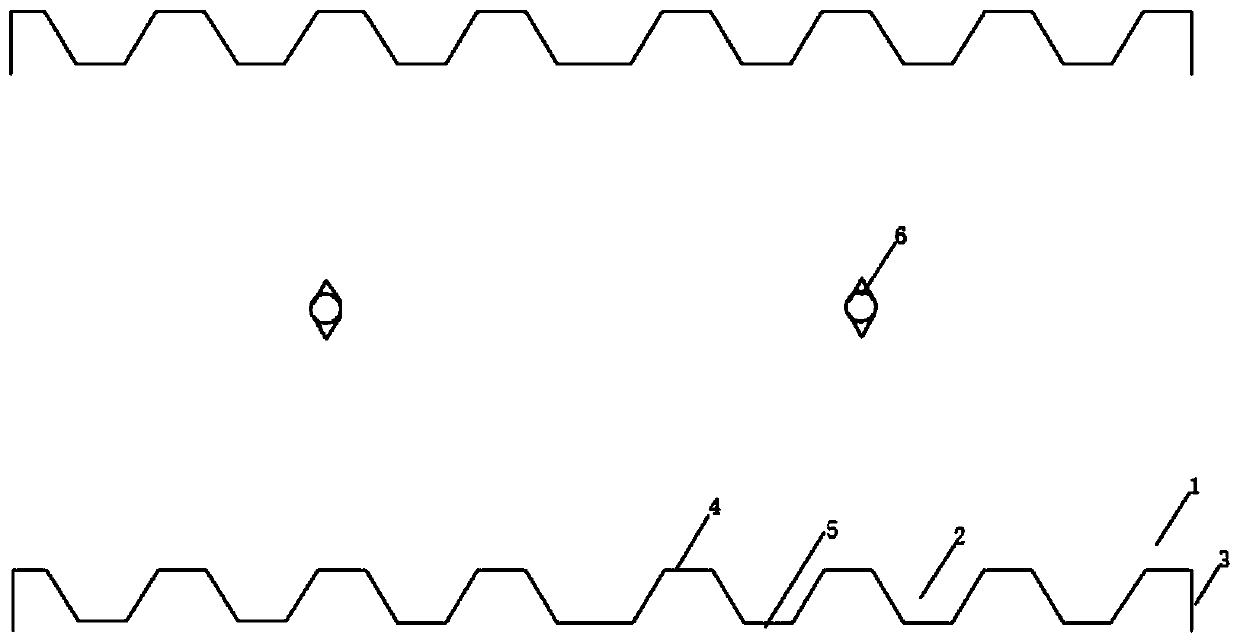

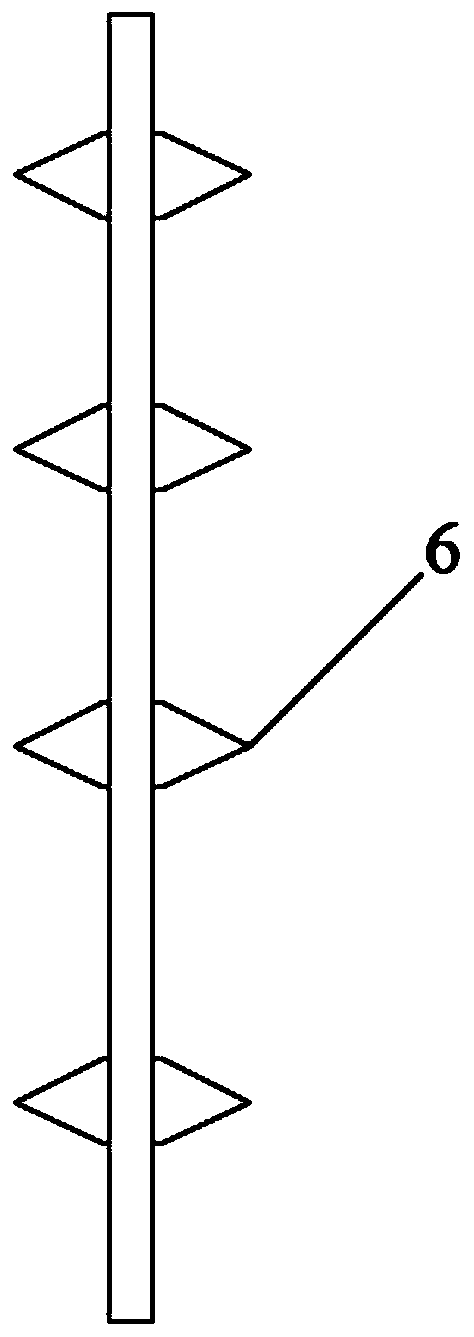

[0073] combined with figure 2 As shown, a new pole matching form involved in this embodiment includes two dust collecting pole plates 1 and several multi-angle double-thorn electrodes 6, the dust collecting pole plates 1 are arranged at intervals, and the dust collecting pole plates 1 pass through The bending method forms a plurality of raised folded plates 4 and grooves 5 arranged at intervals, and a particle trap is formed at the groove 5. The cross section of the groove 5 is an isosceles trapezoid, and the width of the upper bottom of the cross section is 3 to 11 cm. The width is 2-6 cm, the depth of the groove 5 is 1-5 cm, and the angle between the two waists of the groove 5 and the bottom surface of the groove 5 is 100-135°. The dust-collecting pole plate 1 is also provided with a strengthened folded plate 3, and the strengthened folded plate 3 is arranged at both ends of the dust-collected pole plate 1; , the distance between the multi-angle double-thorn electrode 6 an...

Embodiment 3

[0075] Based on a generator set with a capacity of 1000MW in a power plant, the particle size range of the measured flue gas particles is 0.01-0.1μm, and the maximum stable ash concentration of the dust removal device is set to 30g / m 3 , specific resistance ρ of particles r =2×10 12 Ω·cm, for low specific resistance particles, using dry electrostatic precipitator to achieve efficient removal of fine particles.

[0076] combined with Figure 4 As shown, it is the electric field layout and rapping control structure diagram of the high-efficiency electrostatic precipitator with the particle trap dust collection plate in Example 3, wherein the dust collection plate 1 with the particle trap is only arranged on the high-efficiency electrostatic precipitator The fourth electric field is the final electric field.

[0077] combined with Figure 4 As shown, the high-efficiency electrostatic precipitator involved in this embodiment includes four sets of dust-collecting pole plates 1,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove depth | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com