Pressure-differential classification suction pickup sweeper

A differential pressure type, sweeper technology, applied in the field of special vehicles, can solve the problems of reduced service life, fan damage, poor air outlet channel of garbage bins, etc., to achieve the effect of reducing energy consumption and reducing the power of garbage to absorb garbage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

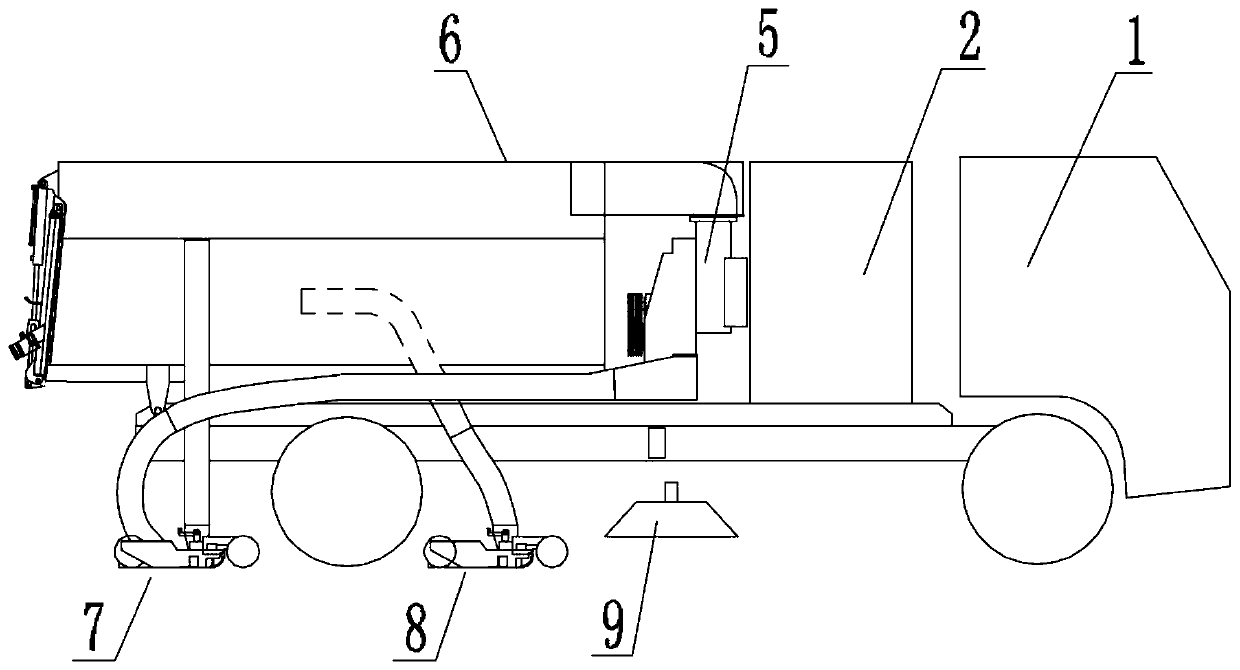

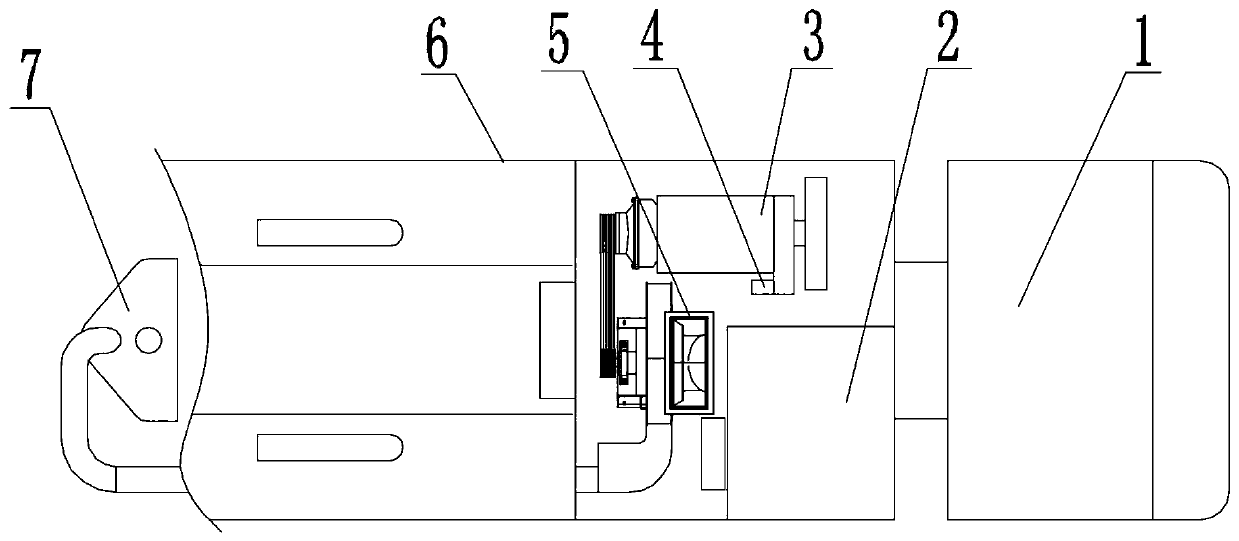

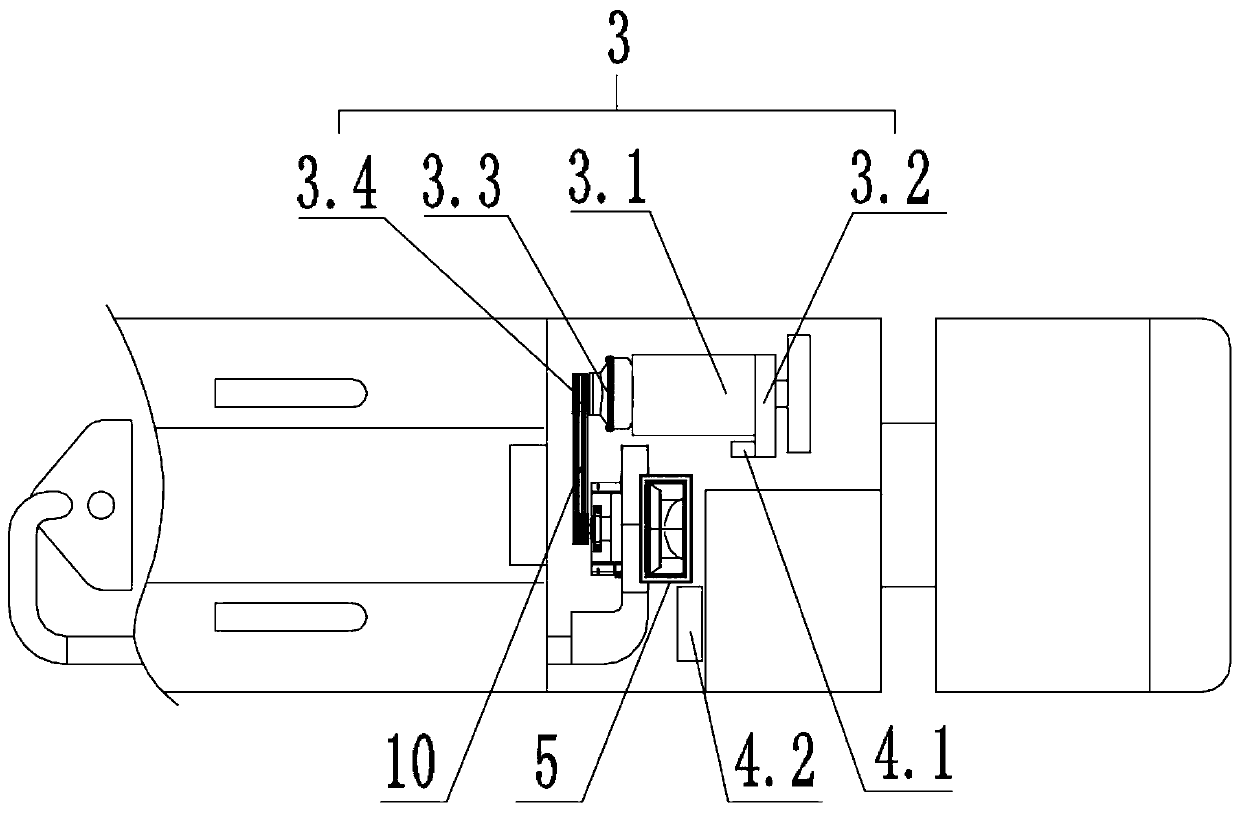

[0068] A kind of differential pressure classification suction cleaning vehicle provided by the present invention, such as figure 1 and figure 2 Shown, comprise automobile chassis 1, be provided with water tank 2, auxiliary engine 3, hydraulic drive system 4, blower fan 5, dustbin 6, rubbish suction pick-up device, cleaning mechanism 9 and cleaning spray system (in the figure) on automobile chassis 1 not shown); where:

[0069] The hydraulic drive system 4 is respectively connected with the cleaning mechanism 9 and other hydraulic actuators, and is used to provide working power for the cleaning mechanism 9 and other hydraulic actuators;

[0070] The auxiliary engine 3 is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com