Pyrohydrolysis method of sludge

A technology of thermal hydrolysis and sludge, which is applied in pyrolysis treatment of sludge, dehydration/drying/concentrated sludge treatment, by-product vaporization, etc. It can solve problems such as sluggishness, easy scaling on the inner wall, uneven heating, etc. , to achieve the effect of improving the effect and preventing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

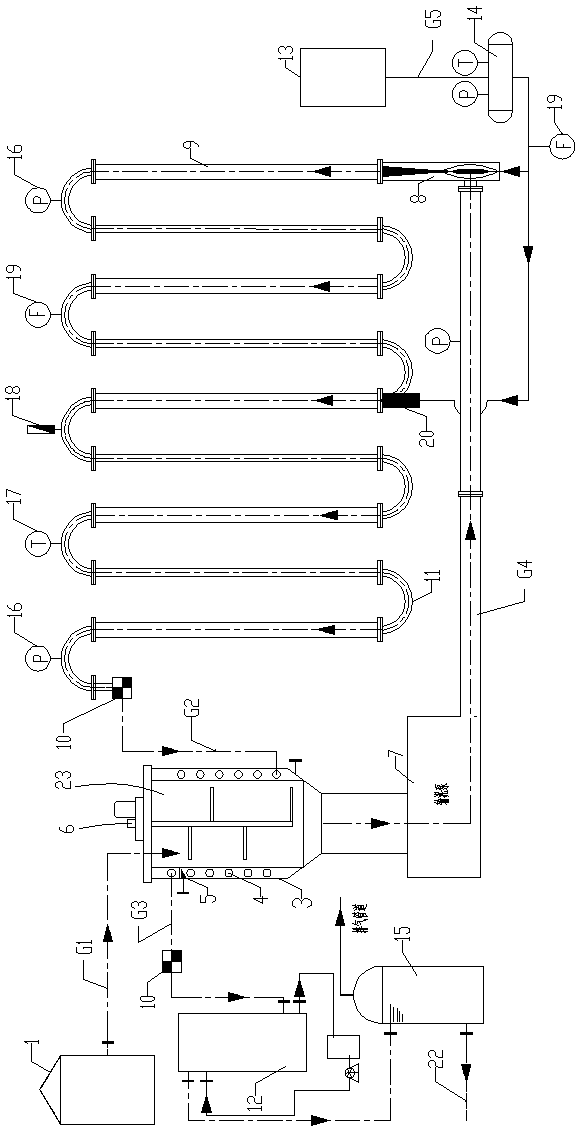

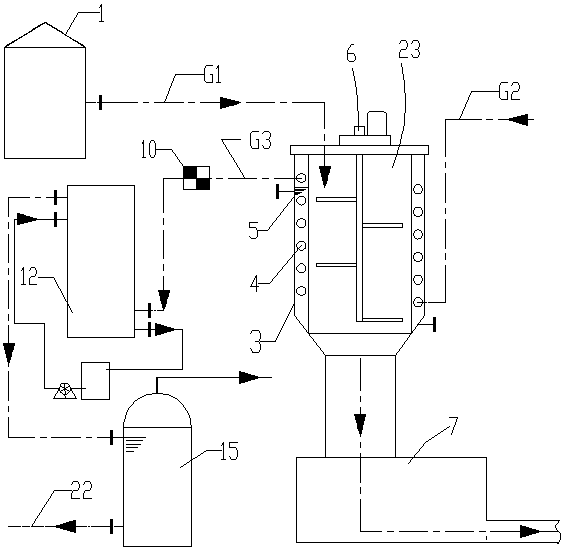

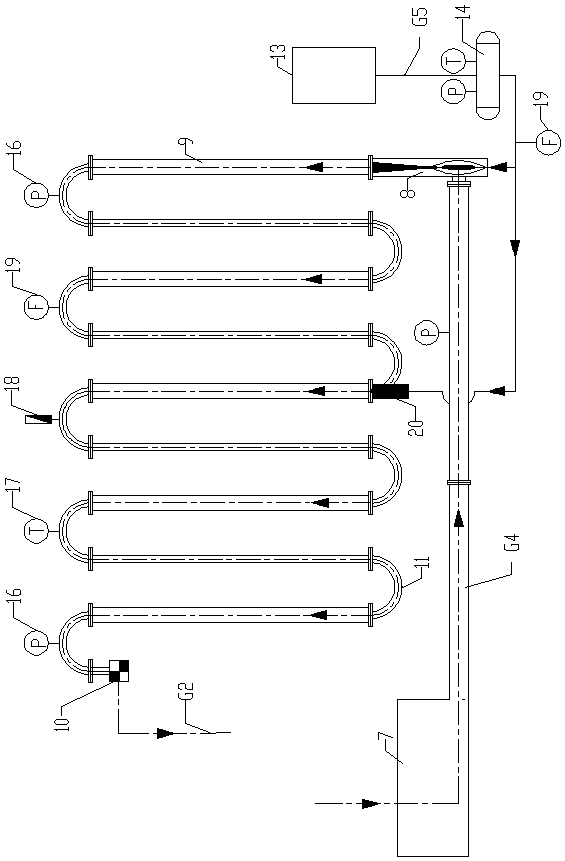

[0033] In order to make the technical solution of the present invention clearer, the following is attached Figure 1 to 4 , The present invention will be described in detail. It should be understood that the specific implementations described in this specification are only for explaining the present invention and not for limiting the protection scope of the present invention.

[0034] The present invention is a thermal hydrolysis method of sludge, including the following steps:

[0035] Step 1: The step of quickly and fully mixing the sludge to be treated with steam

[0036] The sludge to be treated with a certain pressure is passed into the first inlet of the sludge ejector (8), and at the same time, steam with a certain pressure and temperature is passed into the second inlet of the sludge ejector 8. The steam is quickly and fully mixed in the steam sludge ejector 8 and then enters the sludge thermal hydrolysis pipeline;

[0037] Step 2: Thermal hydrolysis in the sludge thermal hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com