Gas-liquid two-phase flow swirl phase separation type capacitor moisture content measuring device

A gas-liquid two-phase flow, measurement device technology, applied in measurement devices, material capacitance, analysis materials, etc., can solve problems such as difficulty in measuring phase holdup, dependence on capacitance sensor response, and difficulty in improving system spatial resolution, and achieve stability. Effective flow pattern adjustment, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below with reference to the accompanying drawings.

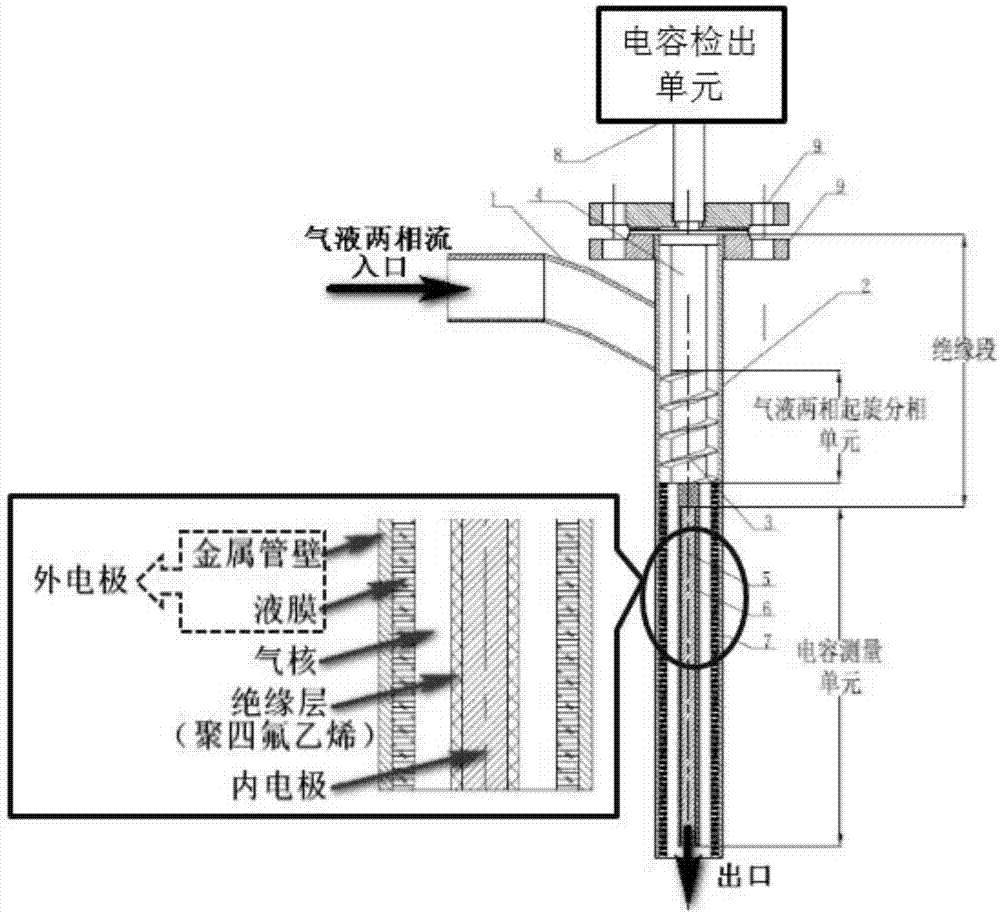

[0024] The present invention is a water content measuring device used in the gas-liquid two-phase flow measurement, the structural diagram is as follows figure 1 shown. The principle of the gas-liquid two-phase flow measurement device is not limited, it can be a flow measurement sensor of any principle, such as various standard and non-standard throttling devices such as cone, Venturi, nozzle and orifice, and can also be used with ultrasonic, Flow meters with different principles such as mass and thermal are used together.

[0025] Such as figure 1 shown. The device of the present invention is installed on a gas-liquid two-phase flow pipeline. The fluid passes through the inlet pipeline 1 and flows into the spinning phase-separation unit 2 tangentially. Natural flow guide without resistance, the spiral blade 3 is firmly connected with the support body 4 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com