Multi-cold water pipe and multichannel heat absorption open-type communicating heat exchanger and manufacturing process thereof

A cold water pipe, open-type technology, applied in the field of multi-branch cold water pipe multi-channel heat-absorbing open-type connected heat exchanger, which can solve the problems of easy scaling and blockage of cold water pipes, poor heat absorption effect, small heat transfer area, etc. , to achieve the effects of stable and reliable production and processing quality, convenient decoration, and expanded heat-absorbing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

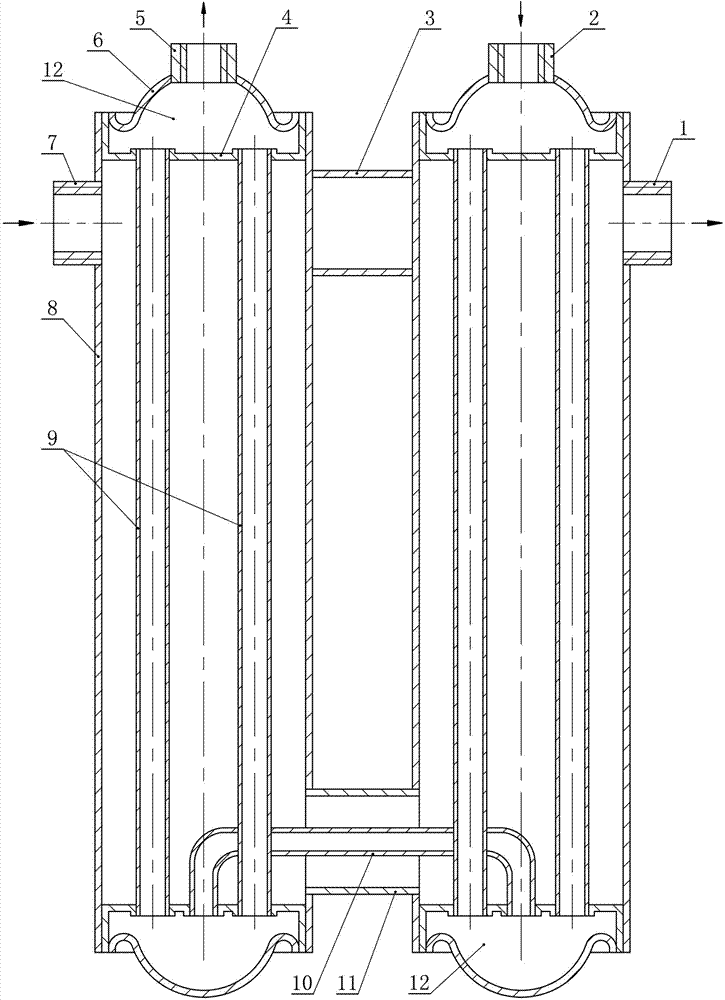

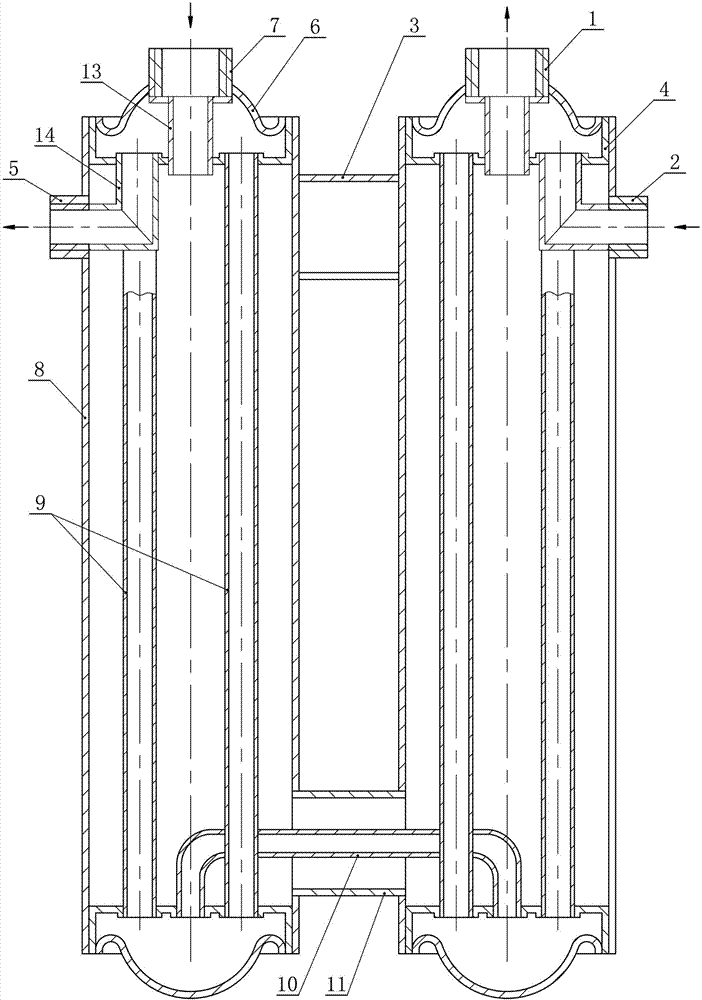

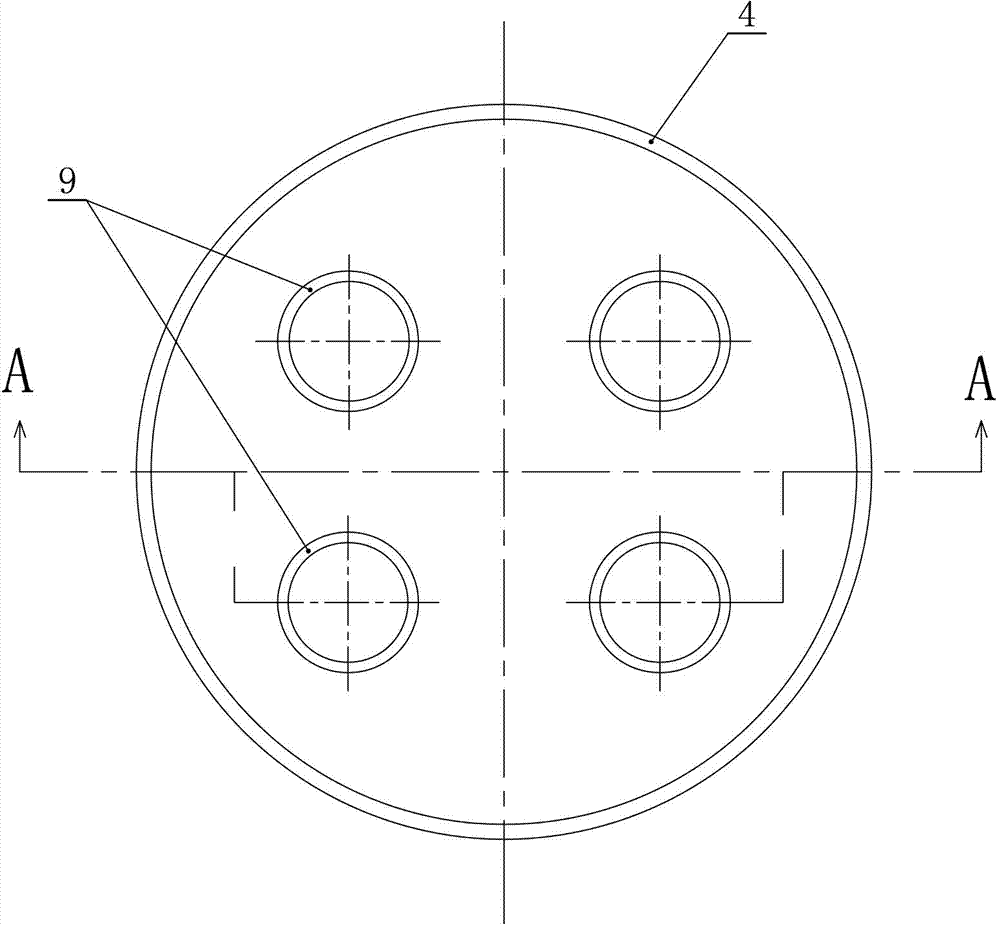

[0045] The present invention includes two or more heat supply pipes. The end of the heat supply pipe is fixedly welded with a porous inner plate and a head plate. The water chamber, the heat supply pipe, and the heat supply pipe are connected to the straight pipe Z-shaped diagonally welded and connected in series to form a heat supply pipe channel; the welding connection of the support piece is a sheet-shaped rectangular whole, and a single or multiple cold water pipes are interspersed in the heat supply pipe; The two ends of the pipe are welded and opened to the porous inner plate, the cold water connecting pipe passes through the heating pipe and is connected to the straight pipe or the straight pipe is connected to the porous inner plate through the welding opening, and the cold water inlet and outlet are connected to the side pipes on both sides of the heating pipe. The cold water heat collecting and distributing chamber is connected by welding, and the heating inlet and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com