Automatic cooling motor construction having driver connected on the back

A drive and motor technology, applied in the field of back-connected drives and motors, can solve the problems of unable to discharge hot air from the drive, poor heat dissipation, and space occupied by external solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order for those skilled in the art to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. The accompanying drawings are only for reference and description, and are not intended to limit the present invention.

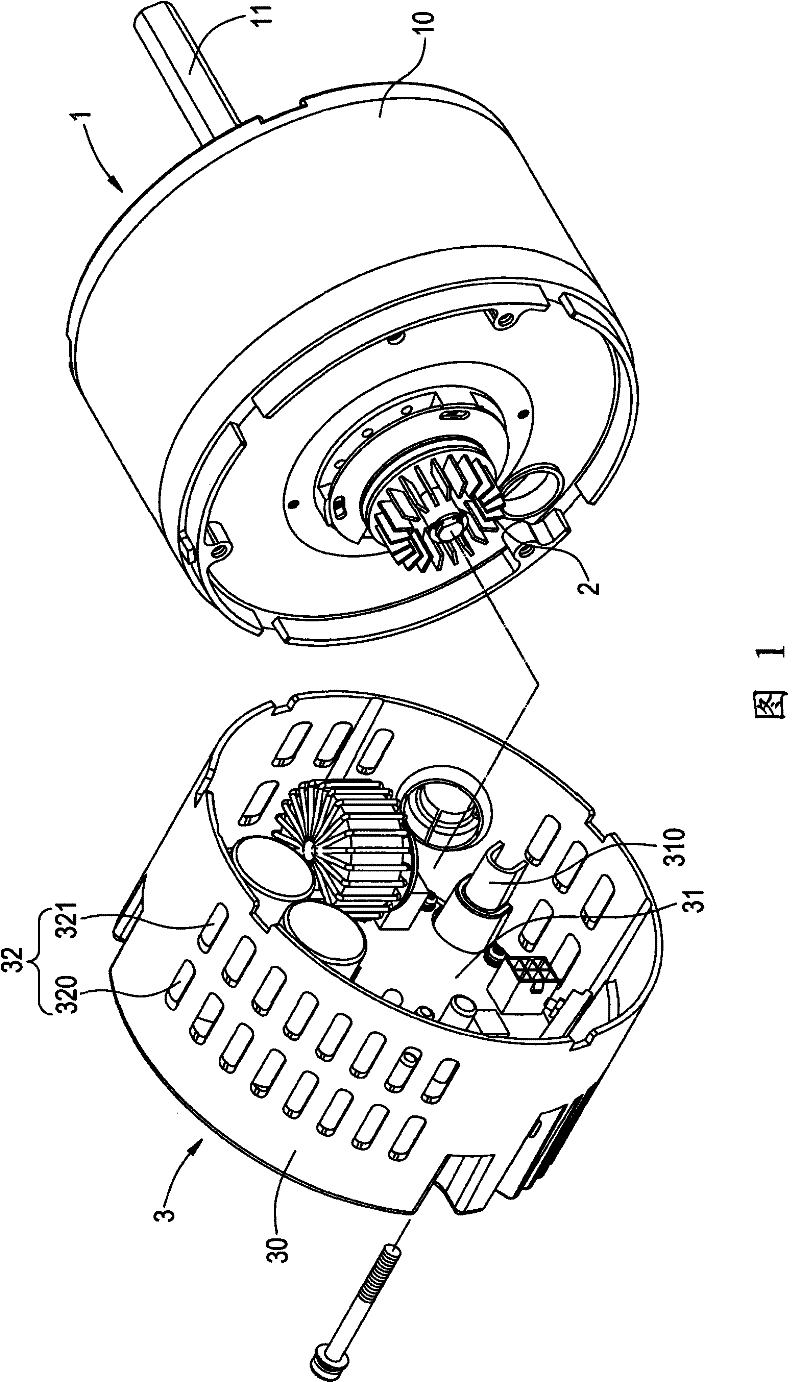

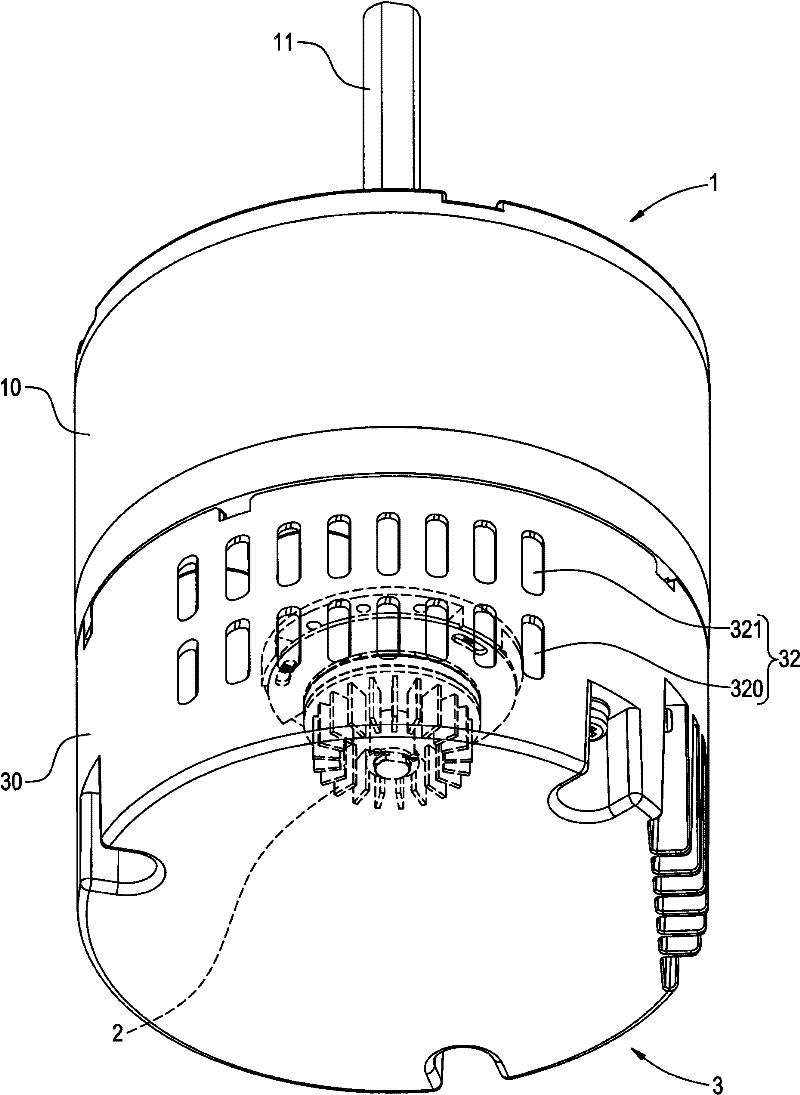

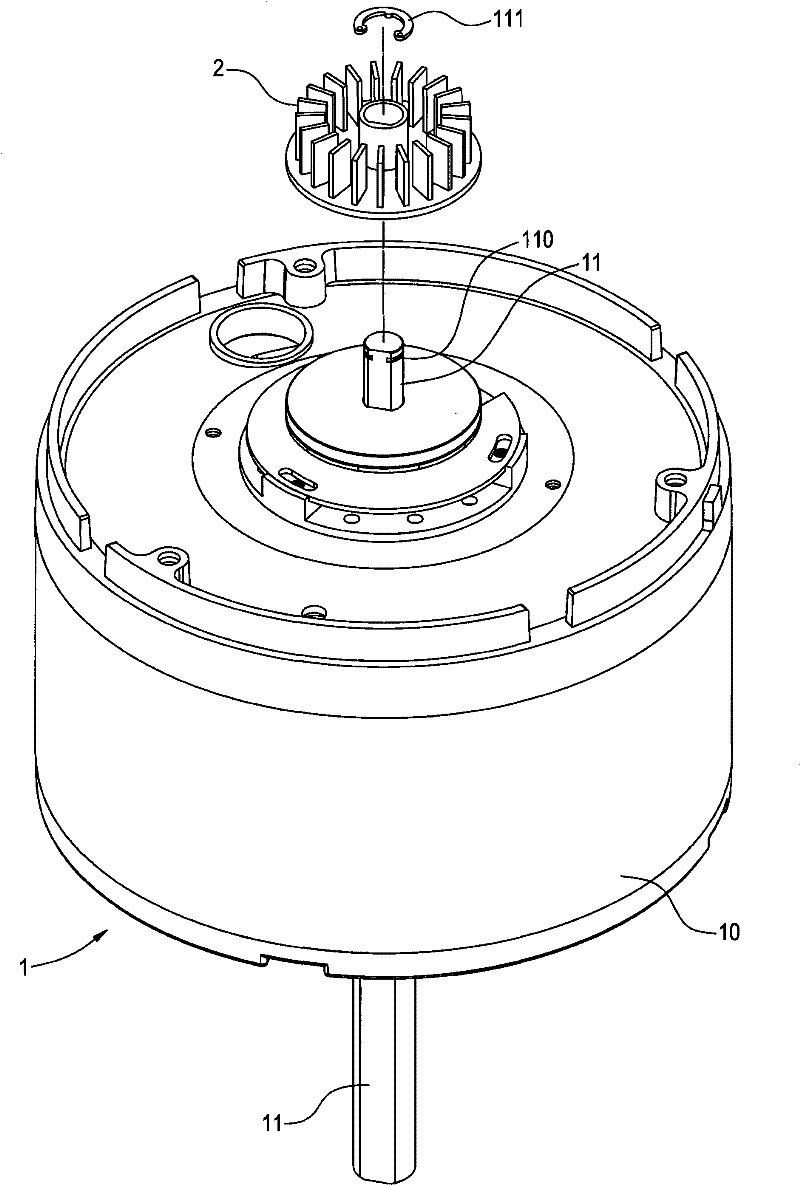

[0027] figure 1 with figure 2 Respectively, the three-dimensional exploded view and the combined schematic view of the present invention. The present invention provides a motor structure with an automatic heat dissipation type back-connected driver, including a motor 1, a centrifugal fan 2, and a driver 3; wherein: the motor 1 is a rotary power device with a motor body 10, and the inside of the motor body 10 is mainly through a stator and a rotor and other components are used to drive the rotation of the rotating shaft 11 pivoted on the motor body 10 . The rotating shaft 11 protrudes at the front and rear ends of the motor body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com