Intensive micropore heat exchanger fin

A heat exchanger, intensive technology, applied in the field of heat exchanger fins, can solve the problems of reducing the structural rigidity of the heat exchanger, poor connection effect, and increasing heat exchange efficiency, so as to facilitate large-scale production and avoid connection The effect is not good, the effect of improving the heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

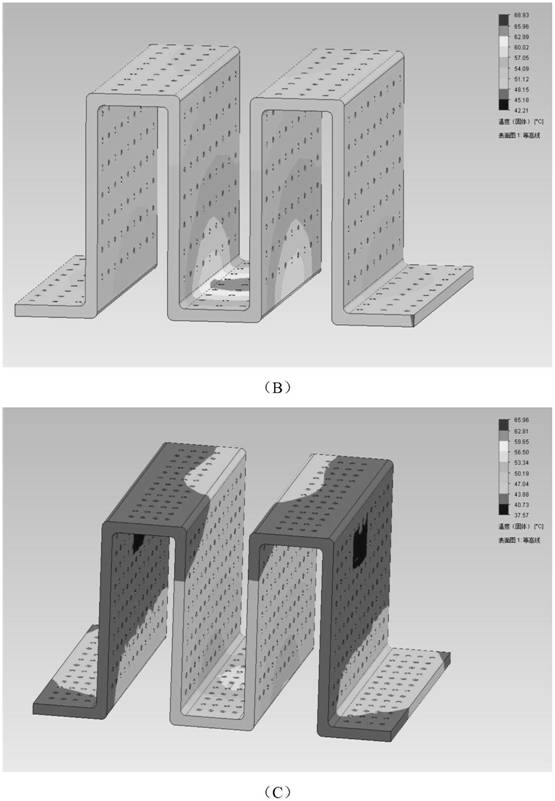

[0040] A dense microporous heat exchanger fin, the fin is provided with densely distributed micropores opened along the thickness direction, the porosity rate is 5-60%, and the porosity rate is the sum of the areas of all micropores / The surface area of the fin, that is, on one surface of the fin, the sum of the hole areas formed by the micropores on this surface / the surface area of this surface of the fin=opening ratio;

[0041]The total area of the micropores is less than the total area of the inner walls of the micropores, and the total area of the micropores is the sum of the area of the holes formed by all the micropores on the upper and lower surfaces of the fins. When the shape and size of the micropores are the same , the total area of the micropores is the product of twice the total number of openings and the hole area of a single micropore, and the total area of the inner walls of the micropores is the surface area increased by the plate along the th...

Embodiment 2

[0047] In this embodiment, the type of the fins is straight (such as figure 2 shown), zigzag (such as image 3 shown), corrugated type (such as Figure 4 Shown) or various combination types, the position of the micropores can be set at will, and the micropores can be located at any position of the fin according to the demand, as long as the heat exchange area is increased, the arrangement of the micropores can be arranged periodically, It may also be a continuous arrangement or a segmented non-periodic arrangement. The fins are suitable for air-cooled heat exchangers, liquid-cooled heat exchangers, and composite structures of the two heat exchange methods.

Embodiment 3

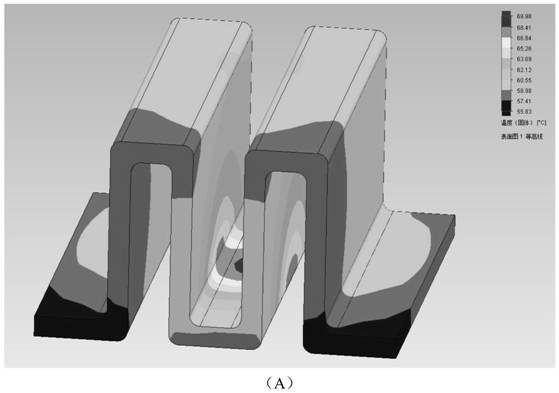

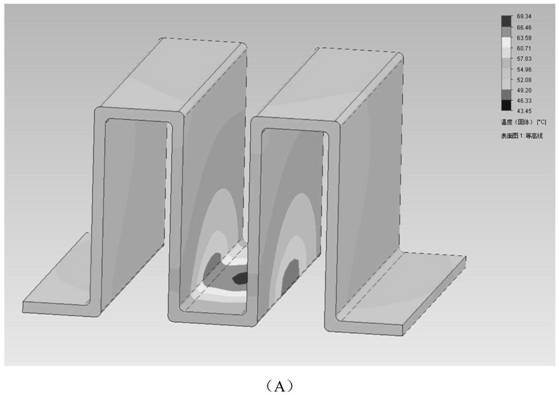

[0049] In order to compare the heat transfer effect of the dense microporous fin structure and the corresponding non-perforated fin structure, the thickness of the three fins with no perforation, 19.3% perforation rate and 25.1% perforation rate are respectively 2mm The same heat source is applied to the heat sink structure of straight fins, in which the micropore diameter is 1mm, and the heat source (chip) and the fin structure are connected by a layer of metal plate, and the heat exchange effect of the two is compared. Among them, the chip size is 11.3mm×7mm×1mm, the heating power is 20W, the cooling method is air-cooled, the wind speed is 5m / s, the airflow is from one side to the other side along the direction of the flow channel, and the ambient temperature is 25 ℃. Figure 5 The straight fin length is 40.65mm, the fin width is 30mm, and the fin height is F h Both are 20mm, fin thickness δ F Both are 2mm, fin spacing F s Both are 5mm. Figure 5 The dense micropores of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com