Vertical type powdered coal drying preheating device based on partition wall heat exchange

A preheating device and vertical technology, which is applied to the field of pulverized coal drying and preheating devices with vertical partition heat exchange, can solve the problems of affecting the economy of the drying and preheating process, inconvenient for user application, and bulky, and achieve low power consumption. , The structure is simple, the effect of increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

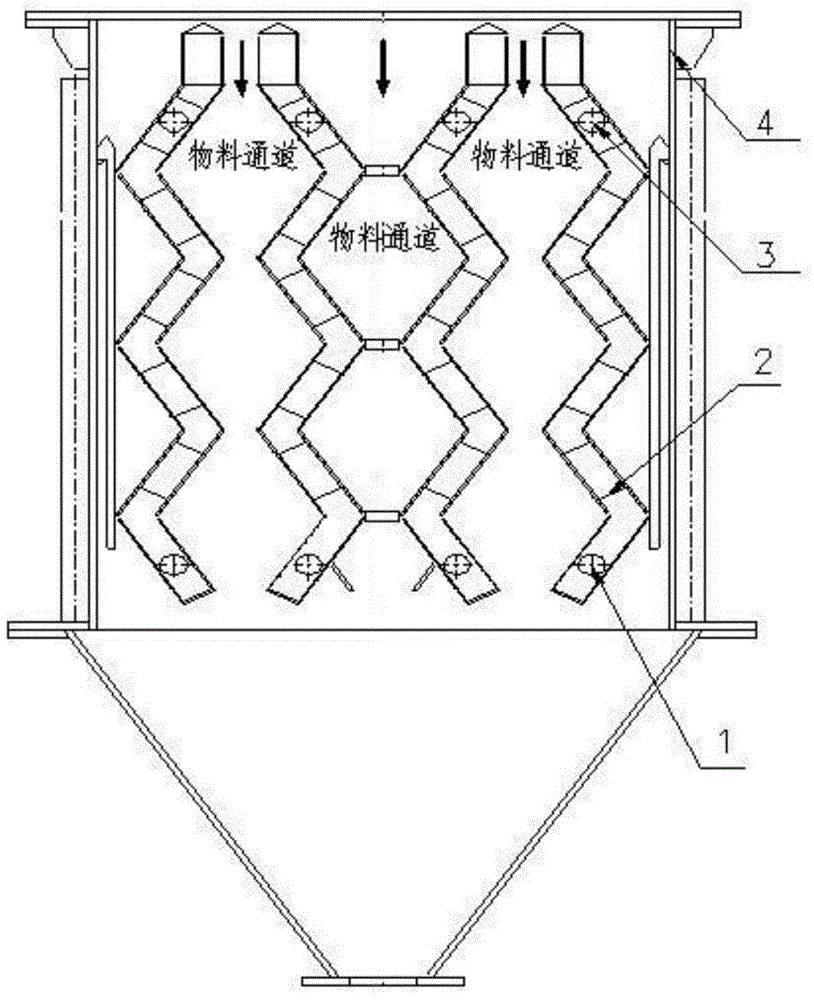

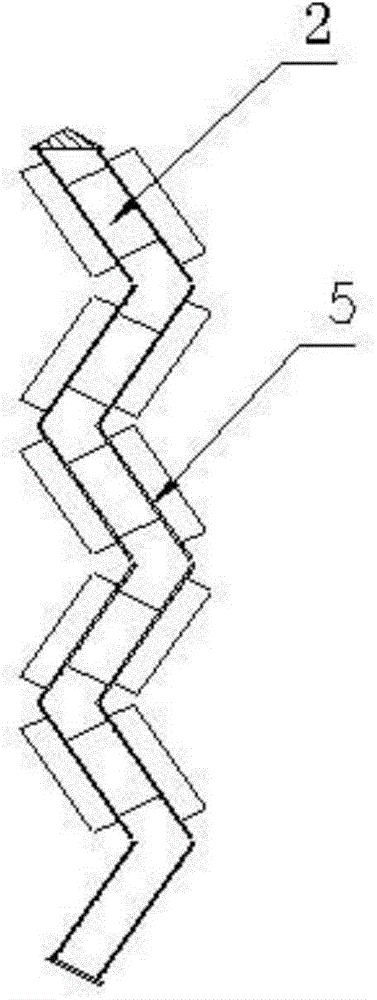

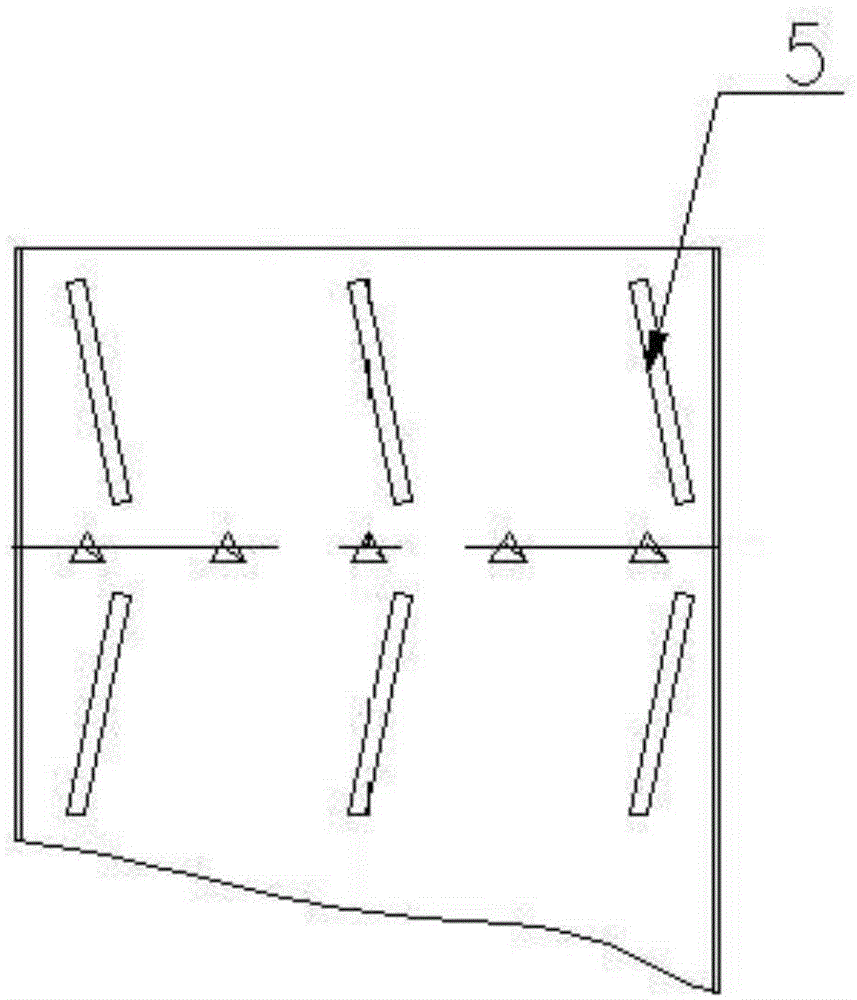

[0016] The shape of the heat exchange cavity of the present invention can be a zigzag or wave-shaped structure. The following is an example of a zigzag structure of the heat exchange cavity, such as Figure 1-3 As shown, a pulverized coal drying and preheating device with vertical partition heat exchange includes an air intake pipe 1, an exhaust pipe 3, a heat exchange chamber 2, a shell 4 and 5 thin-walled plates, and the shell 4 is perpendicular to the ground Installation, the two ends of the 2 heat exchange chambers are respectively provided with 1 intake pipe and 3 exhaust pipes, at least two of the 2 heat exchange chambers are arranged inside the shell 4, and there is a gap between the heat exchange chamber and the heat exchange chamber. There are material channels, and the outer surface of the heat exchange chamber 2 is welded with thin-walled pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com