Dynamic pressure bearing device

A hydrodynamic bearing and bearing technology, which is applied in sliding contact bearings, bearings, bearings in rotating motion, etc., can solve the problems of flow interference of lubricating fluid 120, and achieve the effect of reducing vibration and noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

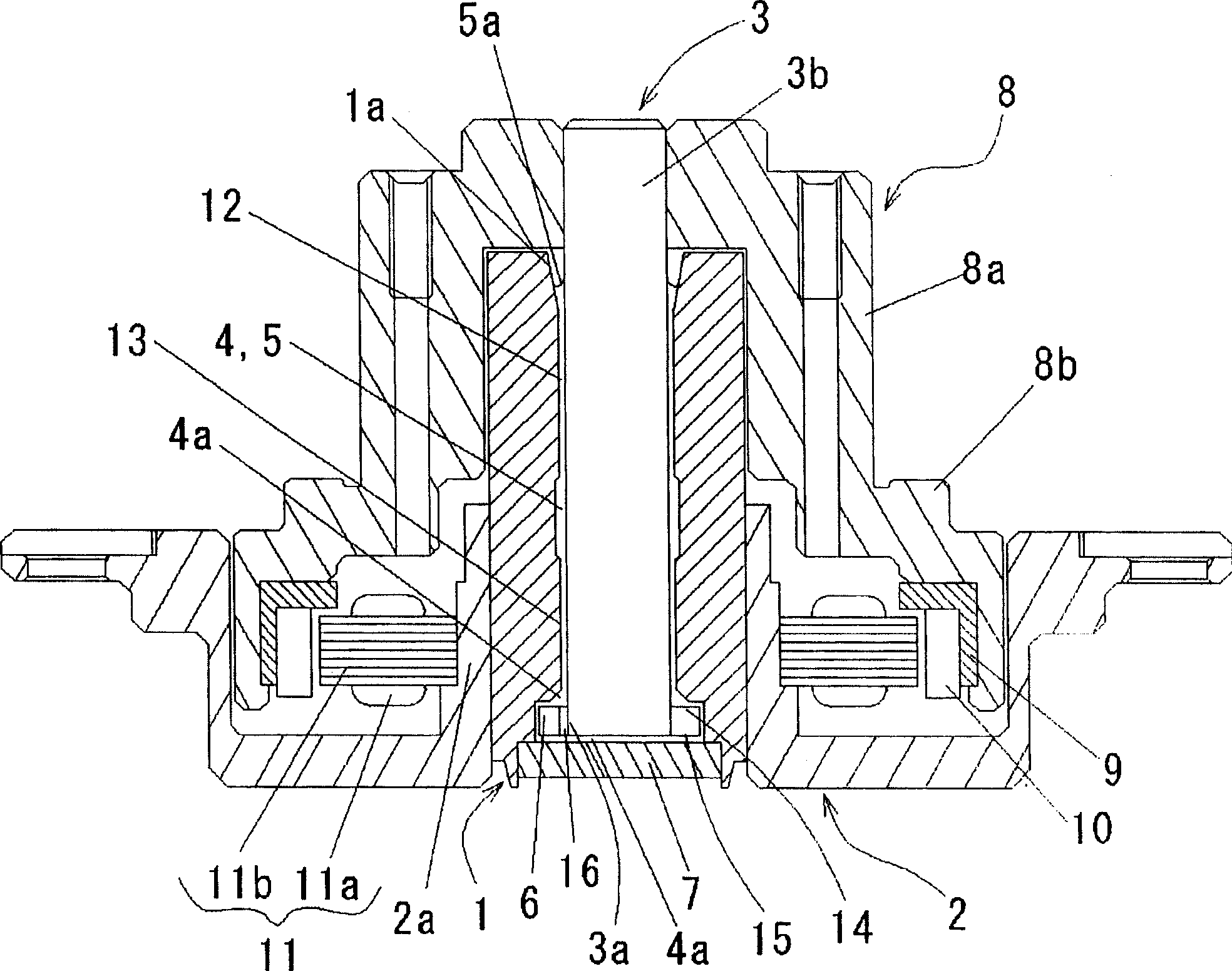

[0030] figure 1 A hard disk drive spindle motor using a fluid dynamic pressure bearing device, which is one configuration of an example of a fluid dynamic pressure bearing device related to the present invention, is shown in . figure 1 is a view of the section in the direction of the axis of rotation.

[0031] will refer to figure 1 An overall description of the spindle motor used to drive the hard disk is given.

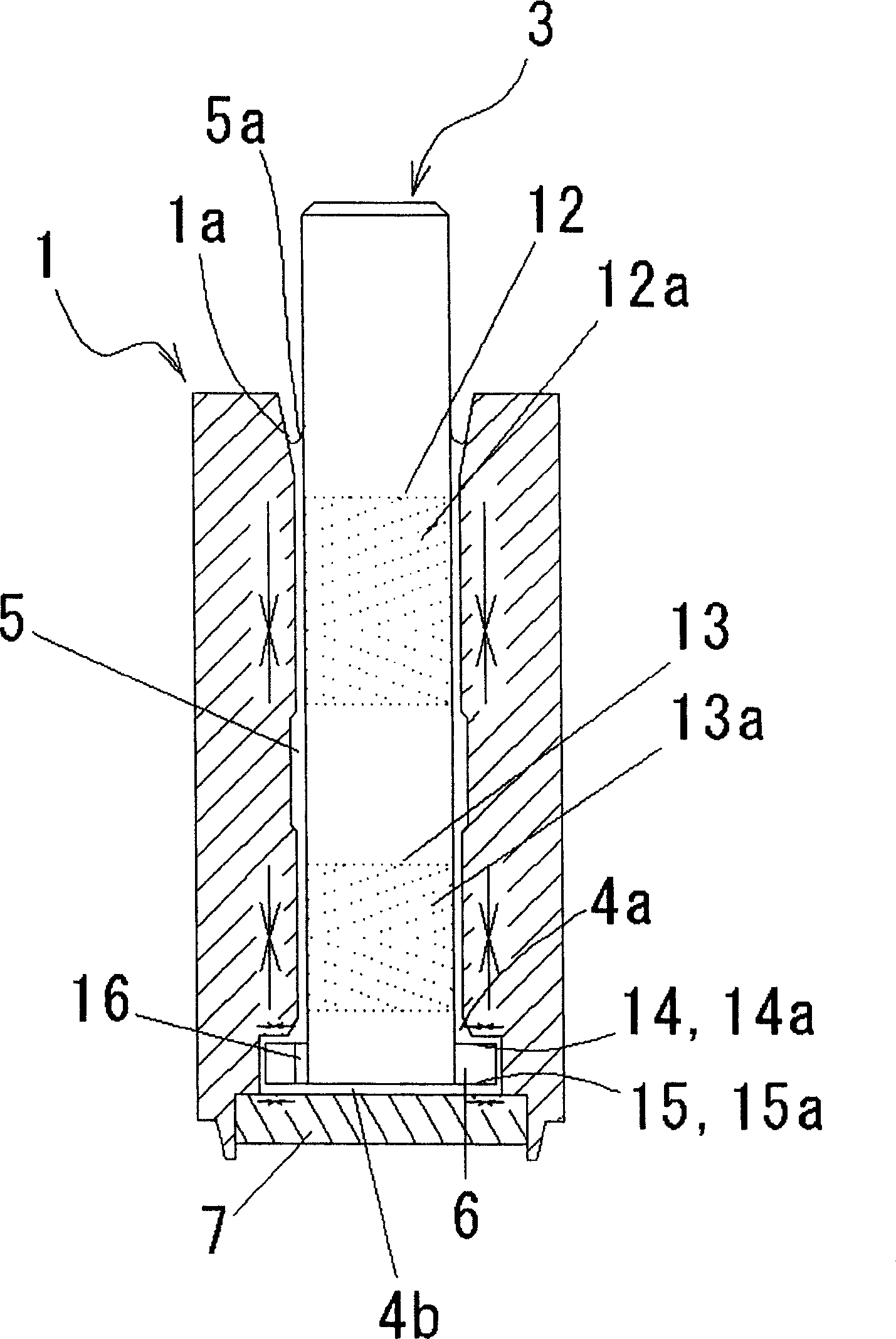

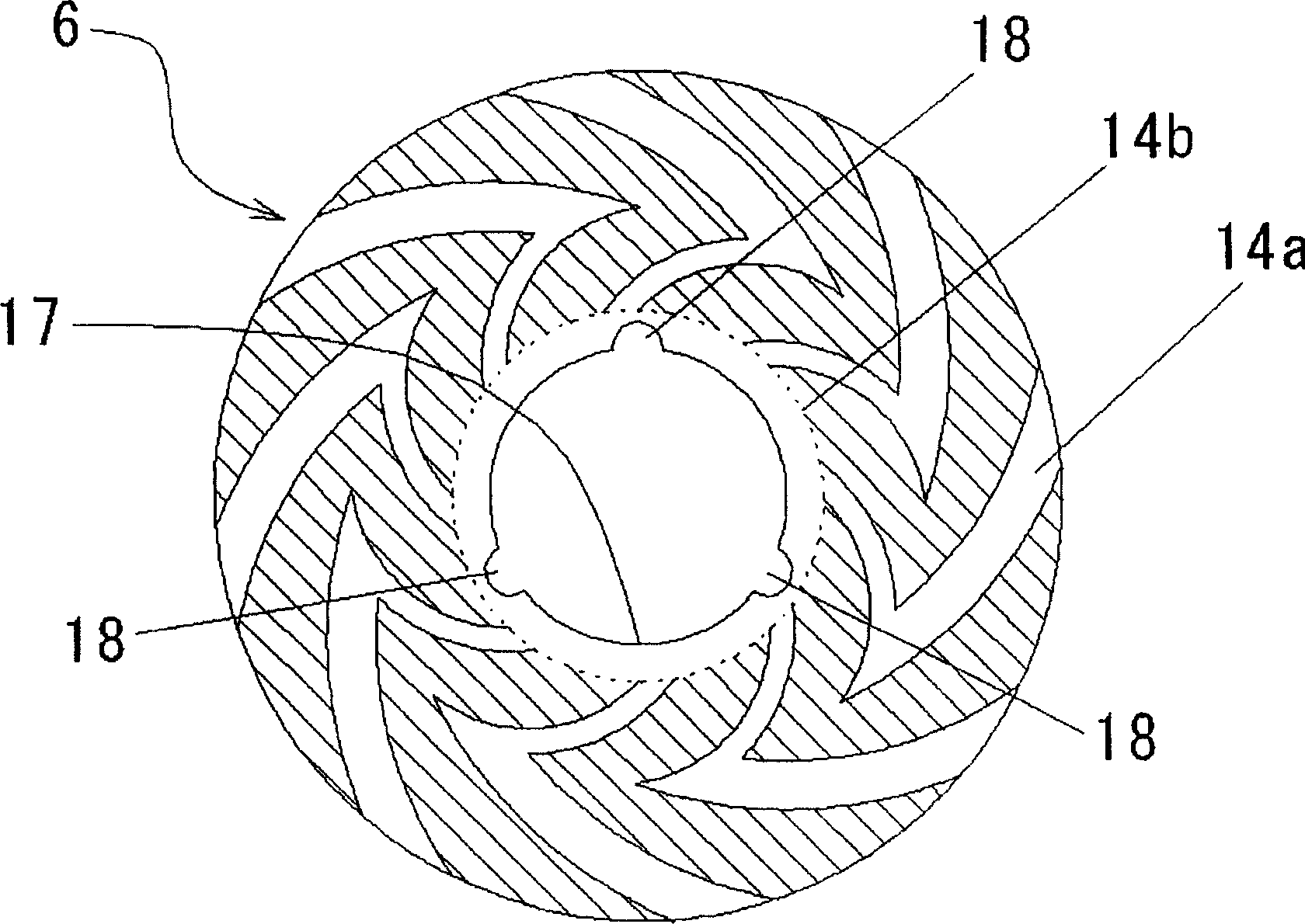

[0032] The bearing sleeve 1 has a hollow cylindrical shape, and the cylindrical housing 2 with the bottom is fixed to the outer circumference of the bearing sleeve 1 by bonding or gluing, for example, which can directly connect the spindle motor to the hard disk drive with screws or the like. the underside of the surface. The shaft 3 as a rotating shaft is inserted into the bearing sleeve 1 with a minute gap 4 interposed between the shaft 3 and the bearing sleeve 1 on the inner circumferential surface of the bearing sleeve 1 . Lubricating fluid 5 , such as oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com