Novel energy-saving aluminum cell with chamfering grooving cathode

An aluminum electrolytic cell and chamfering technology, which is applied in the field of electrolytic aluminum, can solve the problems of electrolytic cell damage, overheating of cathode carbon block, and excessive fluctuation of aluminum liquid, so as to reduce pole distance and cell pressure drop, slow down fluctuation, slow down The effect of reducing flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

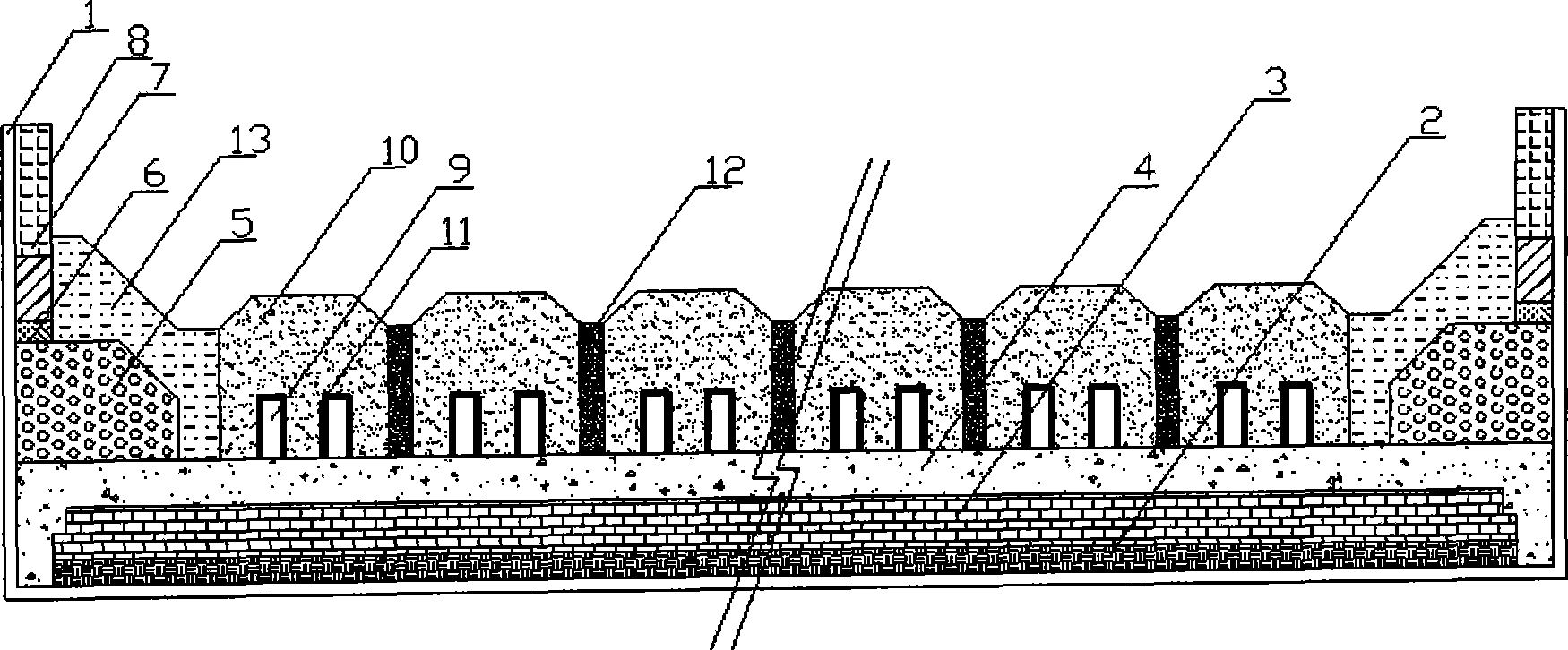

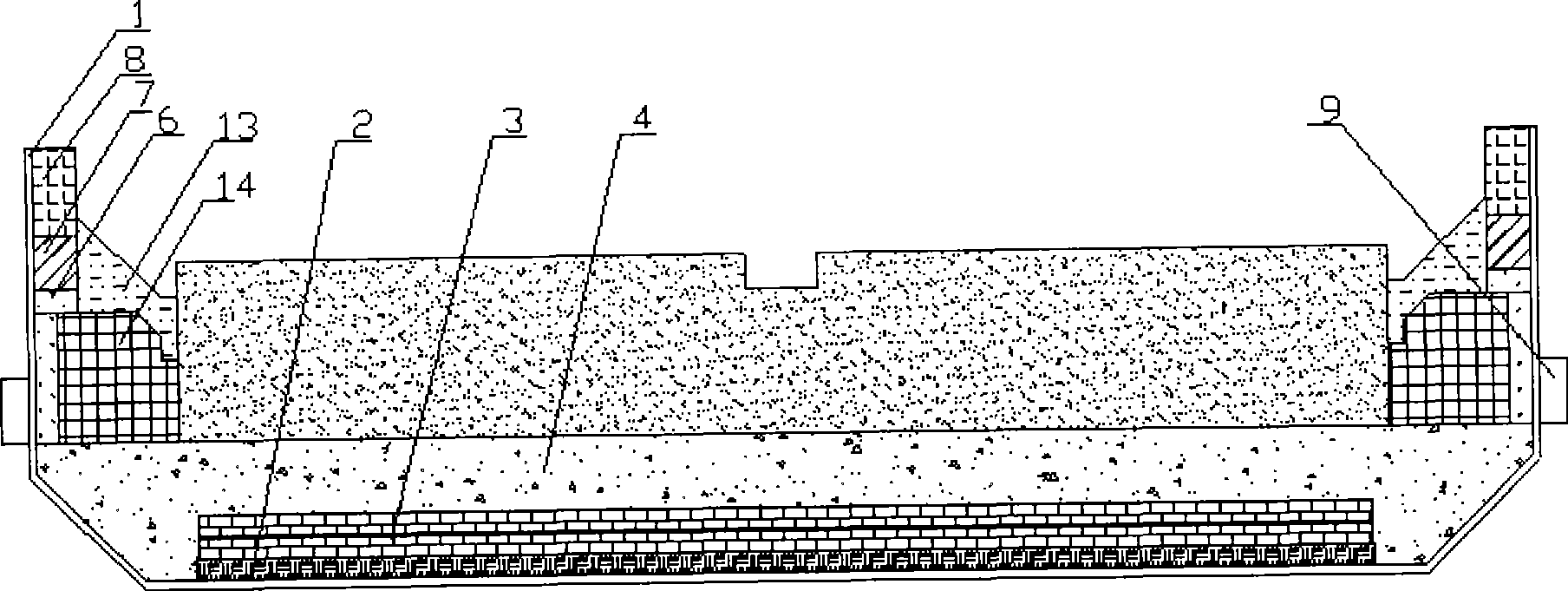

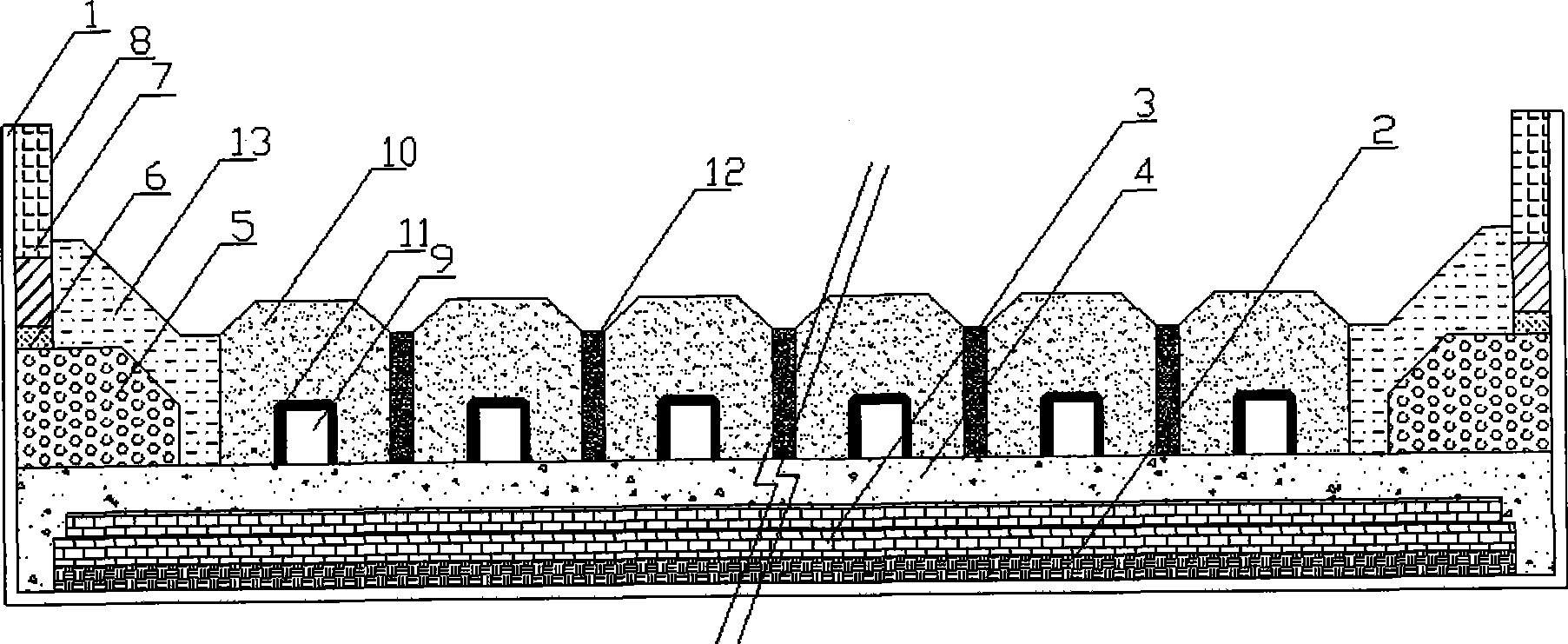

[0041] Such as figure 1 and figure 2 In the electrolytic cell shown in, under the situation that each cathode carbon block is connected with two steel rods, the electrolytic cell construction technical standard of the present invention and the technical process conditions for producing aluminum are as follows:

[0042] 1) When making the cathode carbon block, carry out symmetrical chamfering to the cathode carbon block, the upper part of the cross-section of the cathode carbon block after chamfering is trapezoidal, the trapezoid height is 120mm, the width of the upper bottom is 350mm, and the width of the lower bottom is equal to the width of the cathode carbon block The same is 515mm, the total height of the carbon block (the vertical distance between the upper surface and the lower surface) is 550mm; and a rectangular groove is opened in the upper surface of the longitudinal middle of the carbon block along the transverse direction, the depth of the rectangular groove is 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com