Pumping assistor

An oil pump and rotary mixer technology, applied in the field of pumping aids, can solve problems such as low liquid linear velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

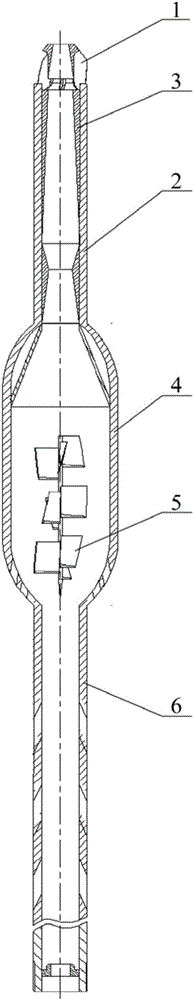

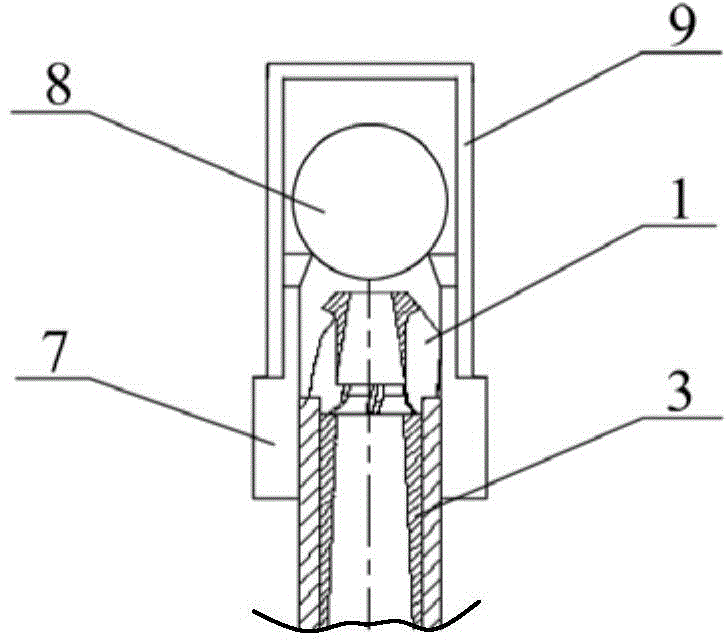

[0031] Such as figure 1 As shown, the embodiment of the present invention provides a pumping aid for an oil well pump, and the pumping aid includes: a screen tube 6, a liquid inlet cylinder 4, a rotary mixer 5, an oil pipe 2, a flow rate changing device 3 and an injector 1.

[0032] Among them, the screen 6 is used to filter oil well produced fluid.

[0033] The liquid inlet cylinder 4 includes an upper section, a middle section and a lower section. The cross-sectional area of the upper section of the liquid inlet cylinder 4 gradually decreases with the flow direction of the oil well output fluid. The lower section of the liquid inlet cylinder 4 is connected to the screen pipe 6 connected to the upper end.

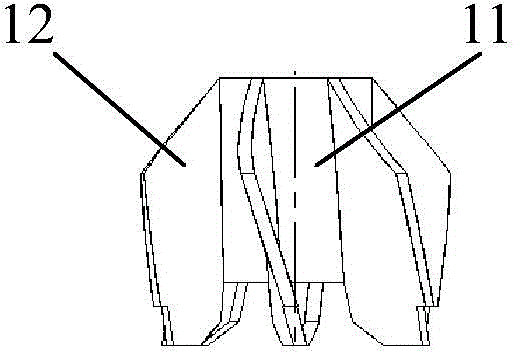

[0034] A rotary mixer 5 is arranged in the liquid inlet cylinder 4, such as image 3 with Figure 4 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com