Semi-conductor perovskite solar cell and preparing method thereof

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of complicated process and expensive perovskite solar cell materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

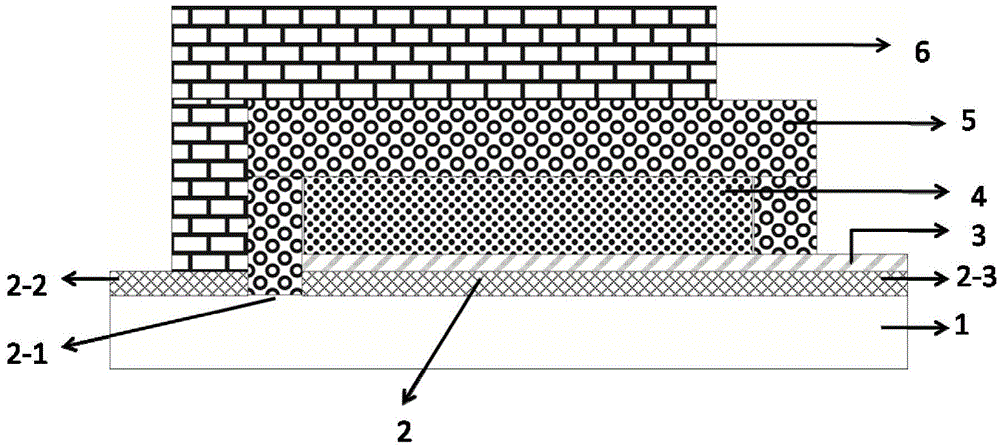

[0077] Embodiment 1, comprises the steps:

[0078] (1) Preparation of the electrode area step: on the commercially available FTO glass, grind it with a grinding wheel, etch a 2mm wide etching groove in the conductive layer, divide the conductive layer on the glass surface into a counter electrode area and a working electrode area, and then The etched FTO glass is cleaned;

[0079] (2) The step of preparing the hole blocking layer: use 0.05mol / L tetraisopropyl titanate ethanol solution as a precursor to spin-coat a layer of precursor film on the working electrode area, and sinter at 450°C for 60 minutes to form a thickness A hole blocking layer of 10nm;

[0080] (3) The step of preparing the mesoporous electron collection layer: using zinc oxide nanoparticle slurry with a particle size of 10 nm, depositing a layer of zinc oxide nanoparticle layer on the hole blocking layer by spin coating, and sintering at 400° C. for 60 minutes, Form a mesoporous electron collection layer wi...

Embodiment 2

[0088] Embodiment 2, comprises the steps:

[0089](1) Preparation of the electrode area step: on the commercially available FTO glass, use a grinding wheel to polish, etch a 2mm wide etching groove in the conductive layer, divide the conductive layer on the glass surface into a counter electrode area and a working electrode area, and then Clean the etched FTO glass;

[0090] (2) The step of preparing the hole blocking layer: using 1 mol / L tetraisopropyl titanate ethanol solution as a precursor, spin-coating a layer of precursor film on the working electrode area, and sintering at 550° C. for 10 minutes, forming a hole blocking layer with a thickness of 100 nm;

[0091] (3) The step of preparing the mesoporous electron collection layer: use a tin oxide nanoparticle slurry with a particle size of 100 nm, deposit a layer of tin oxide nanoparticle layer on the hole blocking layer by screen printing, and sinter at 550 ° C for 10 minutes , forming a mesoporous electron collection ...

Embodiment 3

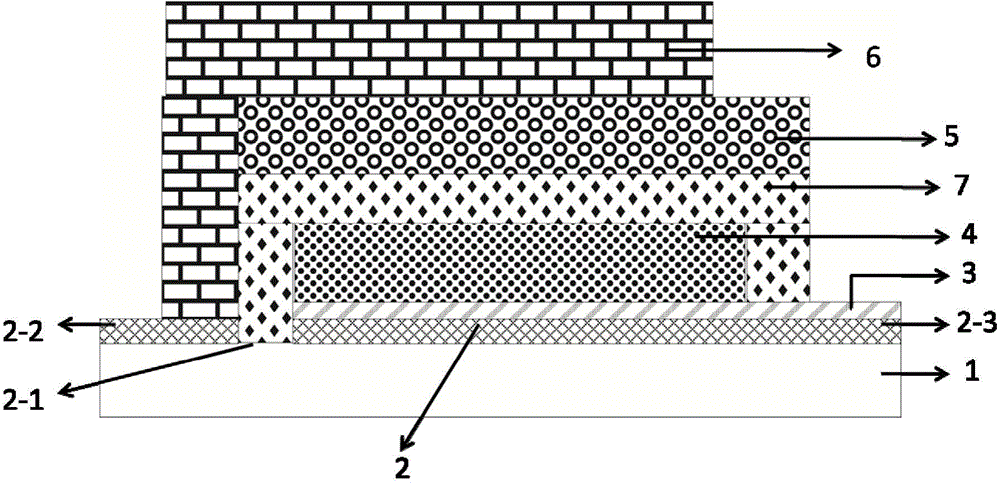

[0097] Embodiment 3, comprises the steps:

[0098] (1) Preparation of the electrode area step: on the commercially available FTO glass, grind it with a grinding wheel, etch a 2mm wide etching groove in the conductive layer, divide the conductive layer on the glass surface into a counter electrode area and a working electrode area, and then The etched FTO glass is cleaned;

[0099] (2) The step of preparing the hole blocking layer: use 0.05mol / L tetraisopropyl titanate ethanol solution as a precursor to spin coat a layer of precursor film on the working electrode area, and sinter at 500°C for 30 minutes to form a thickness A hole blocking layer of 60nm;

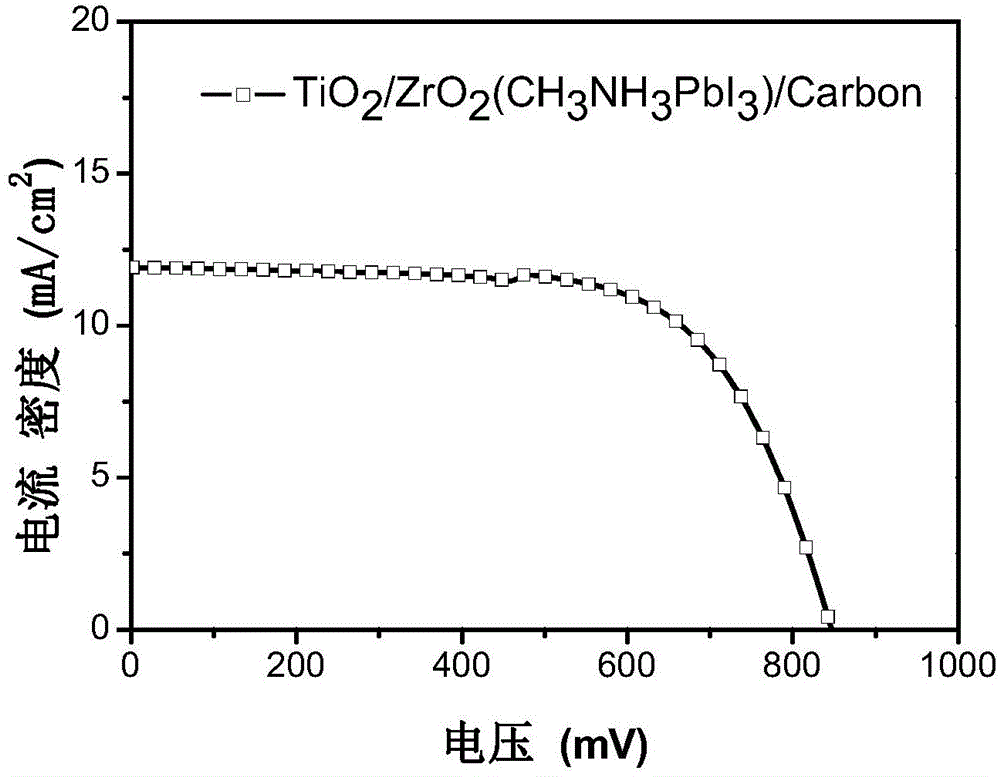

[0100] (3) The step of preparing the mesoporous electron collection layer: use a titanium dioxide nanoparticle slurry with a particle size of 20 nm, deposit a layer of titanium dioxide nanoparticle layer on the hole blocking layer by spin coating, and sinter at 500 ° C for 30 minutes to form a thickness 400nm mesoporous elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com