Three-level rotational flow structure of afterburner head

A technology of afterburner and head, which is applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of limited size of rectifying support plate and limited size of recirculation area, so as to improve uniformity, reduce air flow velocity, The effect of accelerating the atomization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described now in conjunction with accompanying drawing:

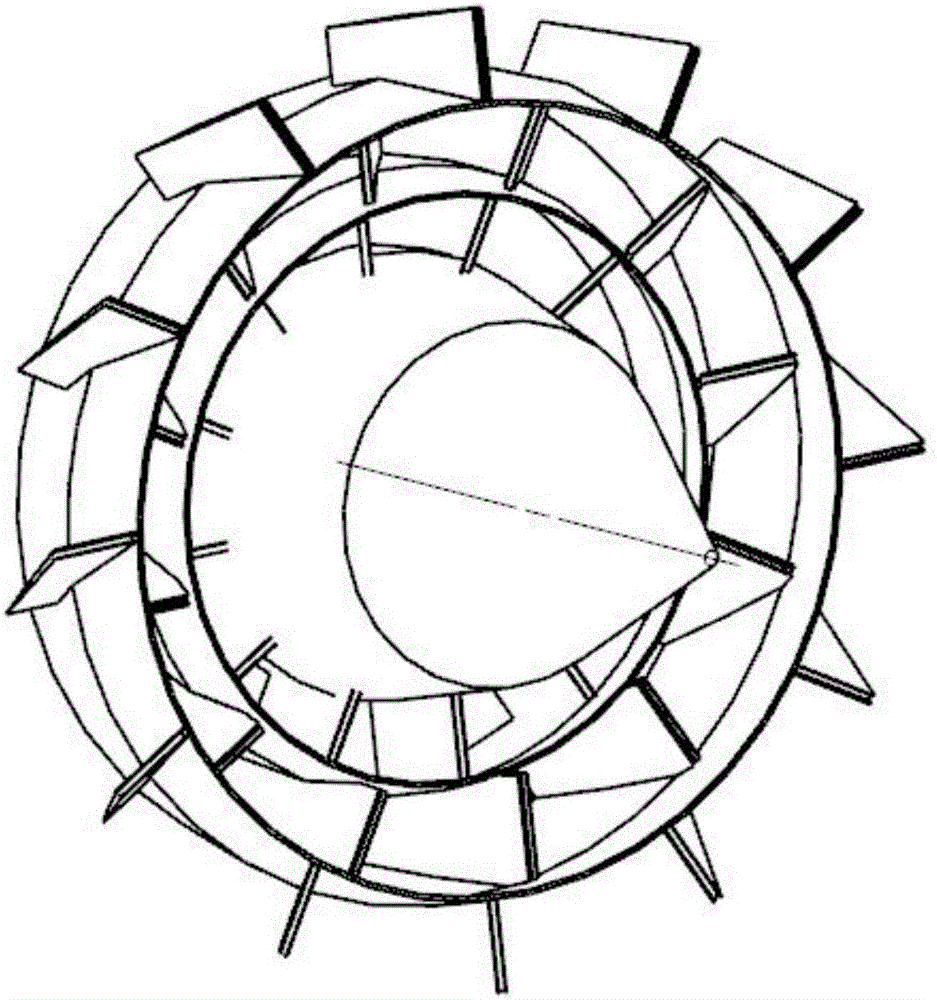

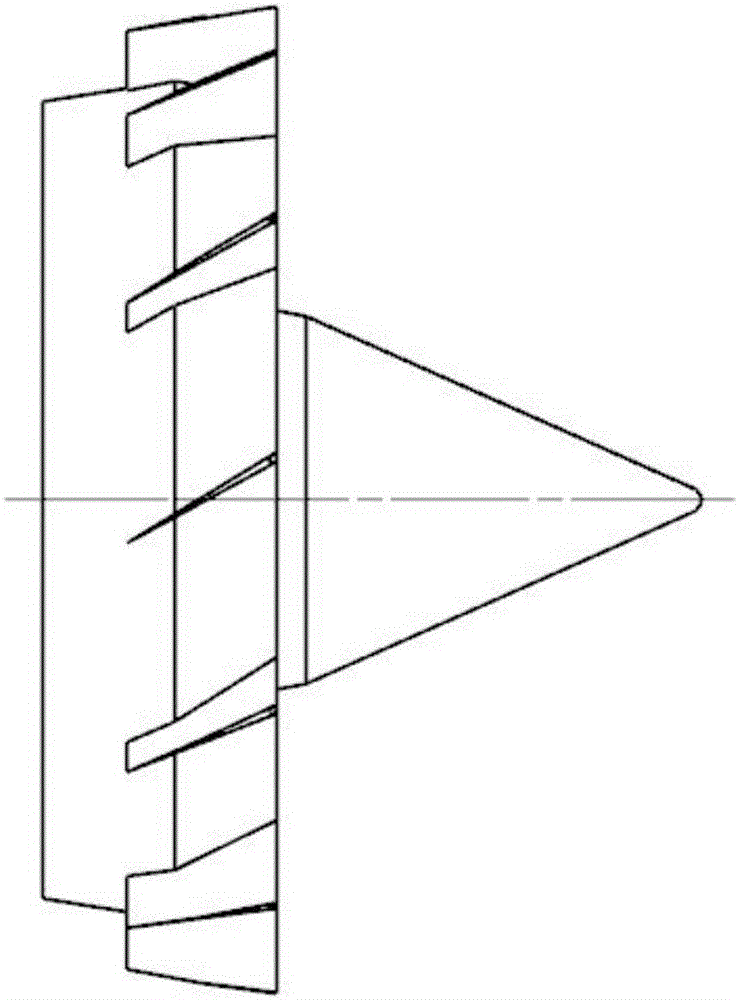

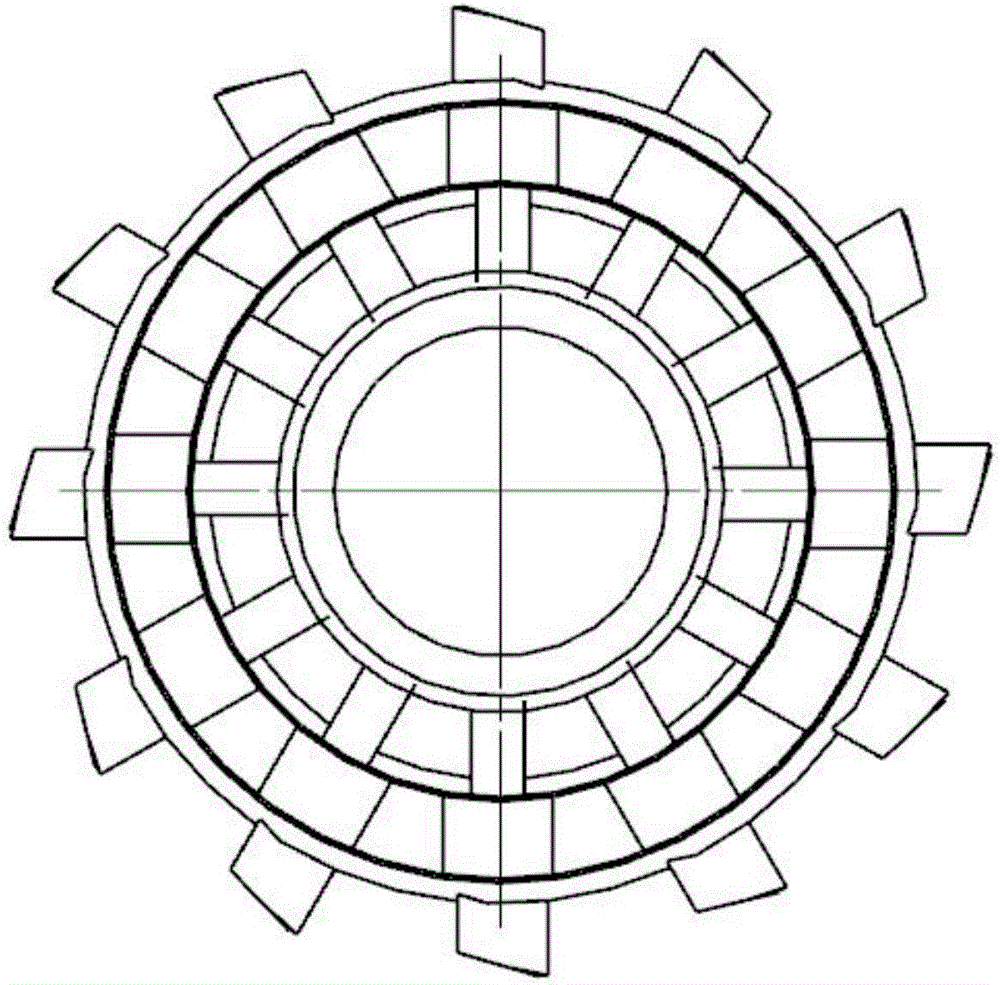

[0024] combine figure 1 , figure 2 and image 3 , The present invention provides a three-stage rectifying strut structure that can change the flow state of the inlet airflow in the afterburner and improve the combustion stability and combustion efficiency in the afterburner. figure 1 is the perspective view of the three-stage rectifier strut, figure 2 It is the side view of rectifying strut plate, image 3 It is the front view of the rectifying struts, and the height distribution of the three-stage rectifying struts can be clearly seen. Figure 4 It is a structural diagram of the entire afterburner.

[0025] In the afterburner, it is very difficult to ignite and maintain a stable flame in the combustion chamber due to the high speed of the intake air flow and the low pressure. The flame will not be blown out by the high-speed airflow, and at the same time, it can main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com