An Improved Radiator Structure

A technology of radiators and heat pipes, applied in the direction of heat exchanger types, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as the inability to increase the contact area without limit, increase the energy consumption of the heat dissipation system, and increase the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, will not be described in detail here.

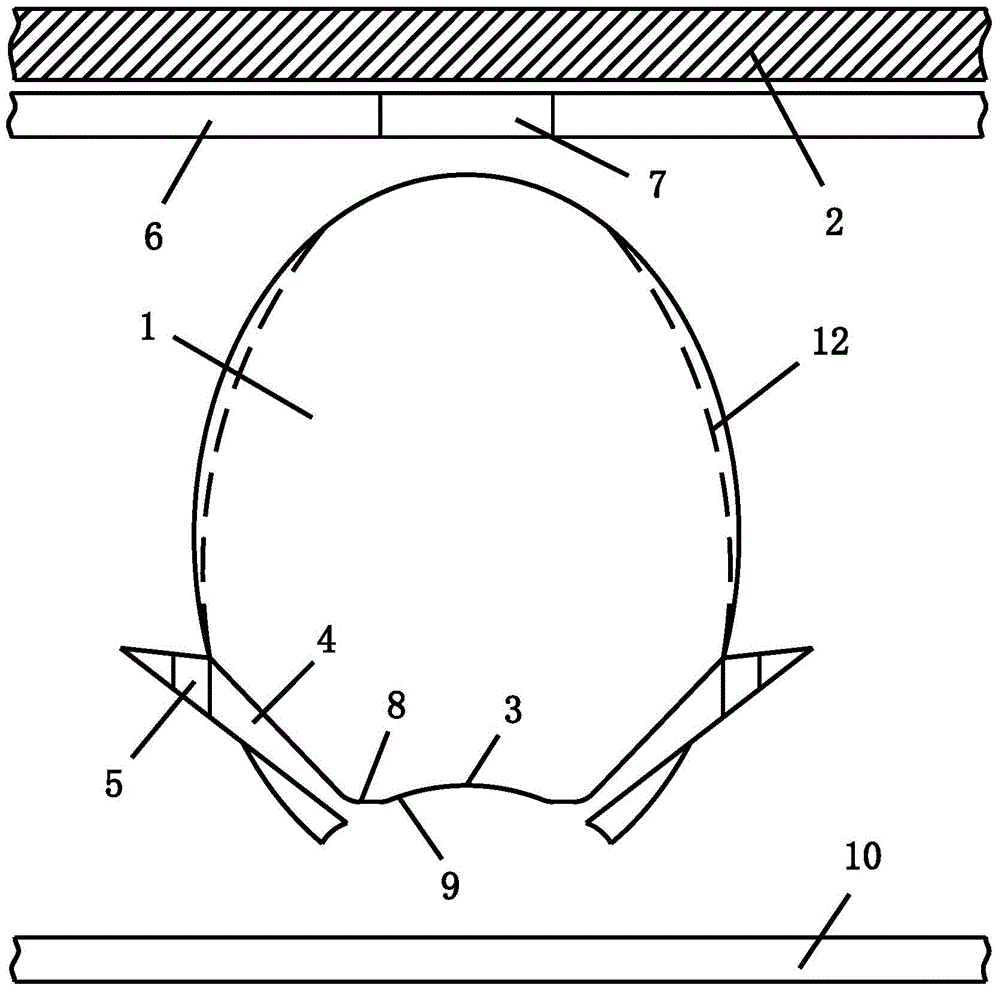

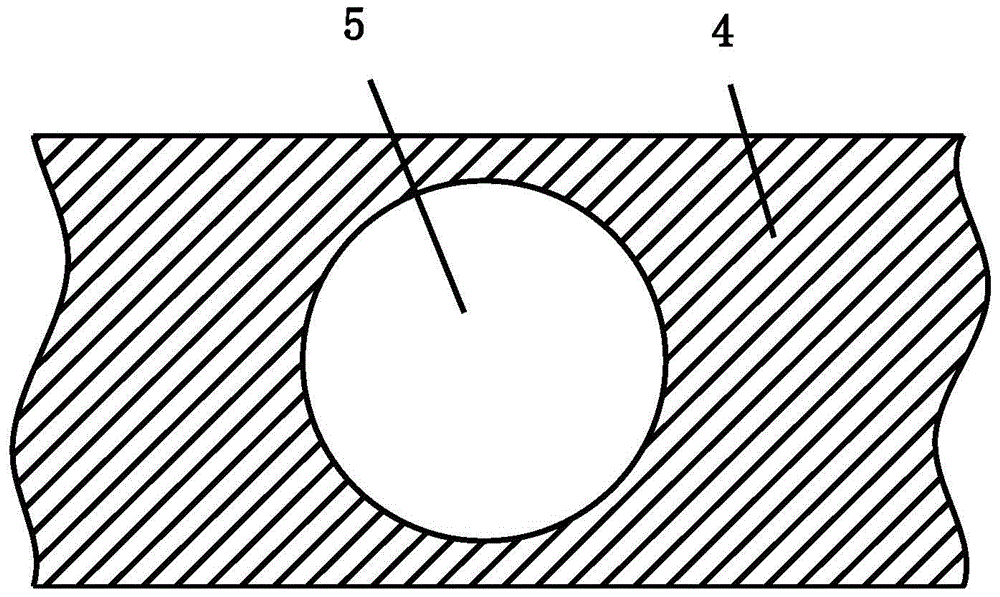

[0018] See attached Figure 2-4 , the specific embodiment includes several large-diameter heat dissipation pipes 1 arranged parallel to each other. The cross-section of the large-diameter heat dissipation pipes 1 is elliptical. The rear side is provided with a heat dissipation fan 2, and the front end of the large-diameter heat dissipation pipe 1 is provided with a first groove 3, and the two sides of the first groove 3 are provided with a through groove 4 communicating with the side of the large-diameter heat dissipation pipe 1, and the through groove 4 is provided with a first air inlet pipe 5, the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com