Gas cooler configuration integrated into heat pump chassis

a technology of gas cooler and heat pump, which is applied in the direction of domestic cooling equipment, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of compromising the efficiency of the heat pump evaporator, and achieve the effect of minimizing the negative impact of the gas cooler on the evaporator and the system performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

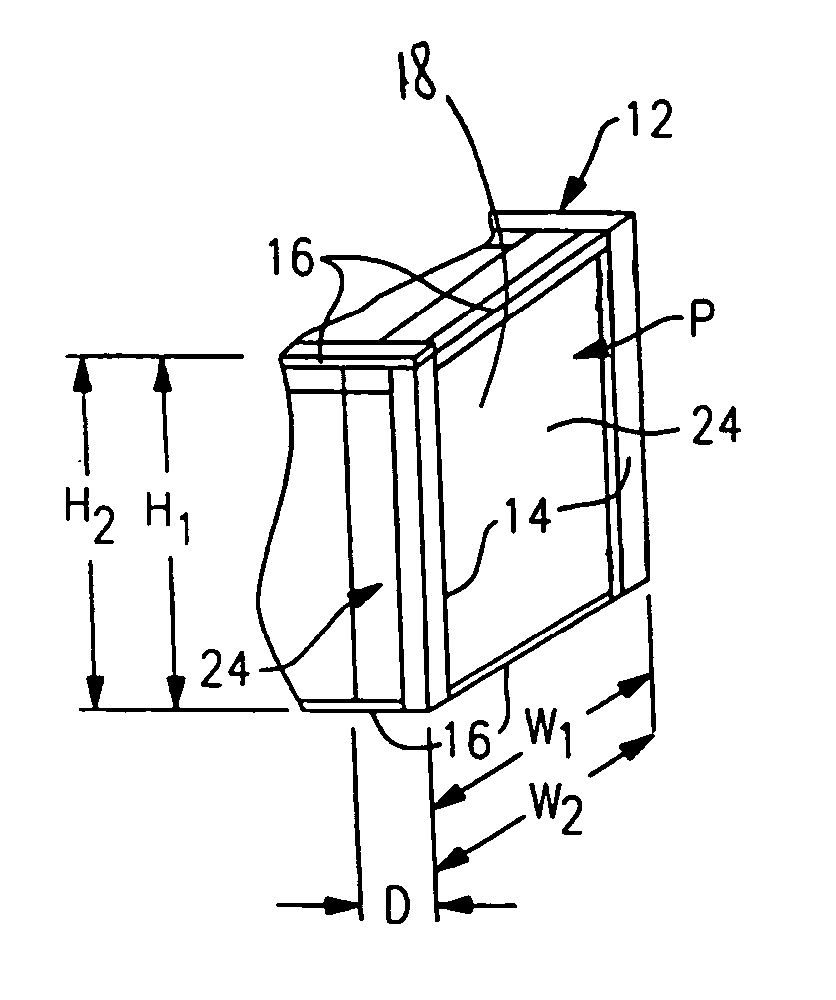

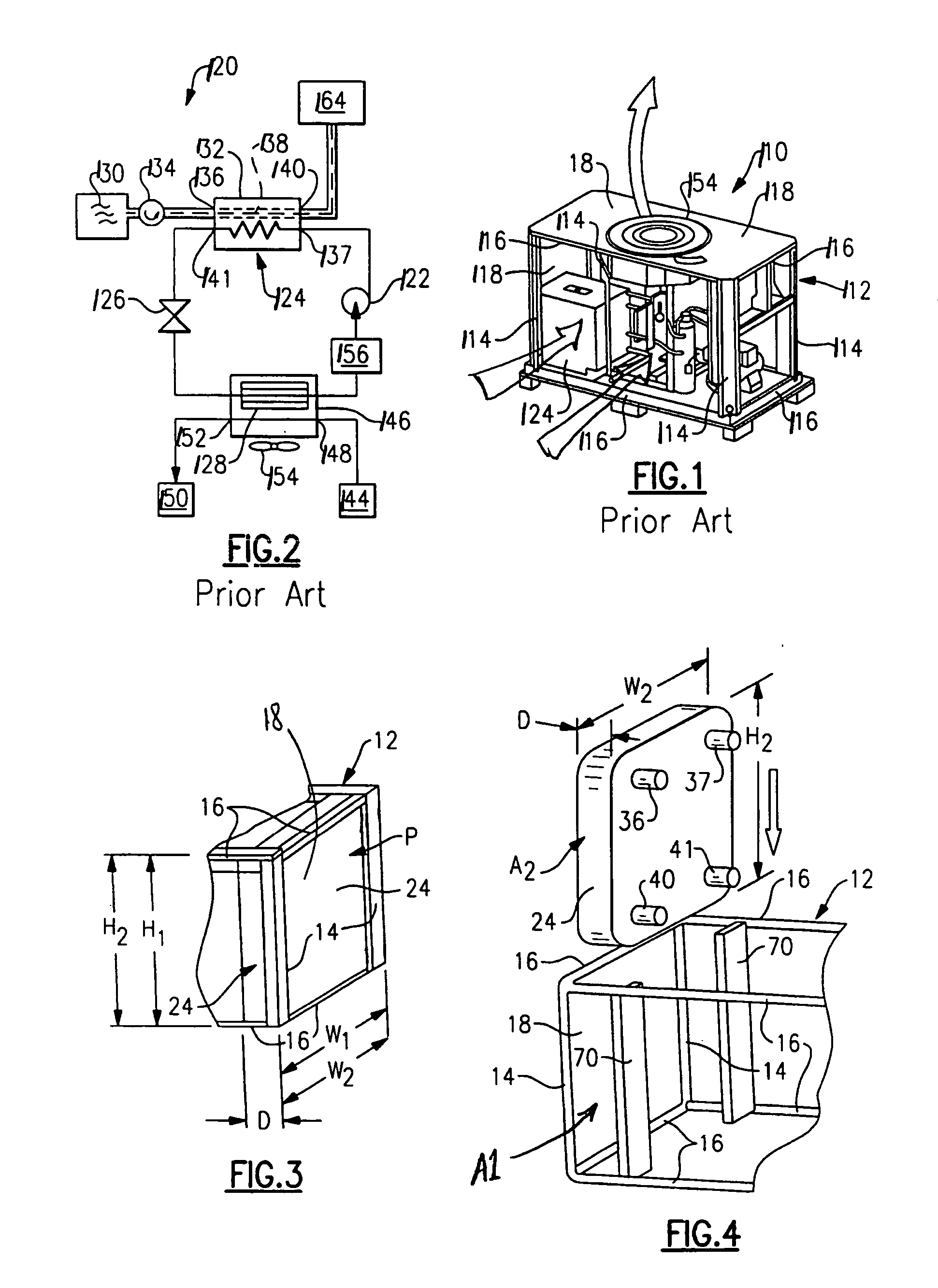

[0015]FIGS. 1 and 2 depict prior art heat pump systems. FIG. 1 illustrates a heat pump water heater 110 having a chassis 112 constructed from multiple vertical 114 and horizontal 116 supports forming a box-like structure for housing the components of the heat pump system 110. Walls 118 are typically supported on the supports 114 and 116 to enclose the components and protect them from the exterior environment. However, the walls 118 are also considered vertical and horizontal supports and together define an outer shape. One of the walls 118 supports a fan 154 for moving air through the chassis to ensure desired operation of an evaporator located within. Maximizing the air flow through the evaporator enables desired heat pump performance during extreme operating conditions.

[0016] As can be seen in FIG. 1, the prior art gas cooler 124 extends a considerable depth into the cavity of the chassis 112 such that it obstructs a significant amount of air flow inhibiting the desired operation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com