Method for homogenizing current distribution in aluminum liquid in aluminum electrolytic cell

A current distribution, aluminum electrolytic cell technology, applied in the field of aluminum electrolytic cells, can solve the problems of reduced current efficiency, increased investment, large bus usage, etc., to achieve the effect of reducing horizontal current, reducing energy consumption per ton of aluminum, and running efficiently and smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

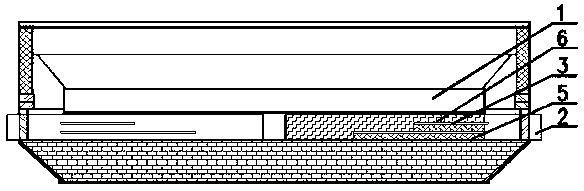

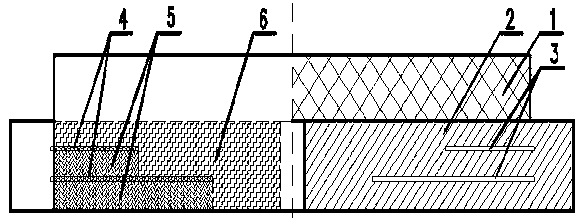

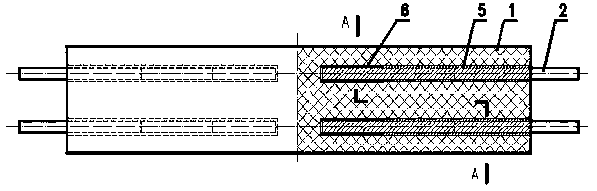

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited by the embodiments.

[0023] As shown in the figure, the present invention is a method for homogenizing the current distribution in the molten aluminum in an aluminum electrolytic cell. At least one cathode steel rod 2 is fastened or cast at the lower part of the cathode carbon block 1, and the cathode steel rod 2 is divided along the length direction by two The separation seam 3 is divided into upper and lower parts, the cathode steel rod 2 and the carbon block 1 between the two separation seams 3 are connected by an insulator 5, and the cathode steel rod 2 and the cathode carbon block in the part below the separation seam 3 are connected 1 is connected by an insulator 5, the rest of the cathode steel rod 2 and the cathode carbon block 1 are all connected by a conductor 6, and the partition 3 is filled wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com