Method for reducing horizontal current in molten aluminum of aluminum electrolysis bath

A horizontal current and aluminum electrolytic cell technology, which is applied in the field of reducing the horizontal current of aluminum liquid in aluminum electrolytic cells, can solve the problems that restrict the development of large-scale tanks, the technological progress of the aluminum industry, the carbon block is easily corroded, and the existence of horizontal current in aluminum liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

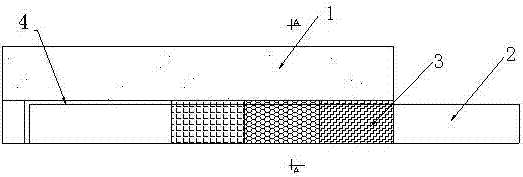

[0031] Such as figure 1 , Figure 5 As shown, the conduction material is laid between the cathode carbon block and the steel rod, and the current conduction material (3) can be laid in various ways as required. Without changing the structure of the carbon block and the steel rod, lay a thin layer of current-conducting material (3) between the carbon block and the steel rod, or first combine it with the steel rod. It can be one or several materials with higher resistivity than the carbon block, or use non-continuously laid insulating materials, which are combined and laid on the outer 1 / 3 or 2 / 3 of the carbon block as required, so as to increase the cathode resistance of this section , to reduce its current flow, thereby reducing the horizontal current in the aluminum liquid.

Embodiment 2

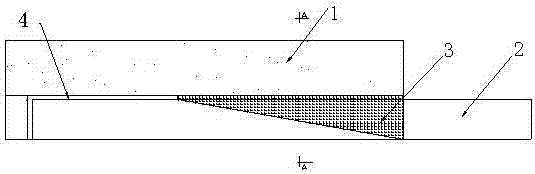

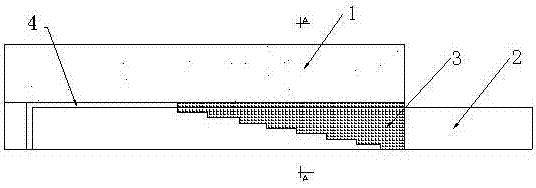

[0033] Such as figure 2 As shown, the conduction material (3) is laid between the cathode carbon block and the steel rod, and the current conduction material (3) can be laid in various ways according to needs. Without changing the structure of the carbon block and the steel rod, lay a thin layer of current-conducting material (3) between the carbon block (1) and the steel rod (2), which can be a material with a resistivity greater than that of the carbon block Or insulating material, laid between the carbon block (1) and the steel rod (2), through the change of the shape of the guide material, its length can be laid from the position of the top of the steel rod or a certain position in the middle to the outlet of the steel rod The electricity is aligned with the edge of the charcoal block. The upper surface of the steel rod completely covers the width of the steel rod, such as Figure 5 As shown, the side part gradually widens from the inside to the outside, or widens i...

Embodiment 3

[0035] Such as Figure 6 , 7 , 8, and 9, the current conduction material (3) is embedded in the carbon block to replace part of the steel rod. As shown in the figure, a material with a lower resistance than the steel rod is used to replace part of the steel rod at the top of the inner end of the steel rod , its length can be less than or equal to the length of the steel rod in the carbon block, its width is the same as that of the steel rod, and its height gradually decreases from the inside to the outside or decreases in steps such as Figure 6 , 7 As shown, the height of the corresponding steel bar material (2) below the flow guide material (3) gradually increases from the inside to the outside, until the height of the steel bar does not change at the place where there is no flow guide material (3) above. The closer the cathode is to the internal resistance, the smaller the electrical conductivity inside the cathode is, so that the current in the aluminum liquid is mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com