Inner lining structure of cathode molten pool for aluminum electrolytic cell

An aluminum electrolytic cell and electrolytic cell technology are applied in the field of the lining structure of the cathode molten pool of the aluminum electrolytic cell, which can solve the problems of increased electrolyte pole distance, increased voltage drop at the bottom of the tank, increased horizontal current, etc., and achieves uniform vertical current distribution, The effect of reducing the voltage drop at the bottom of the tank and reducing the horizontal current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

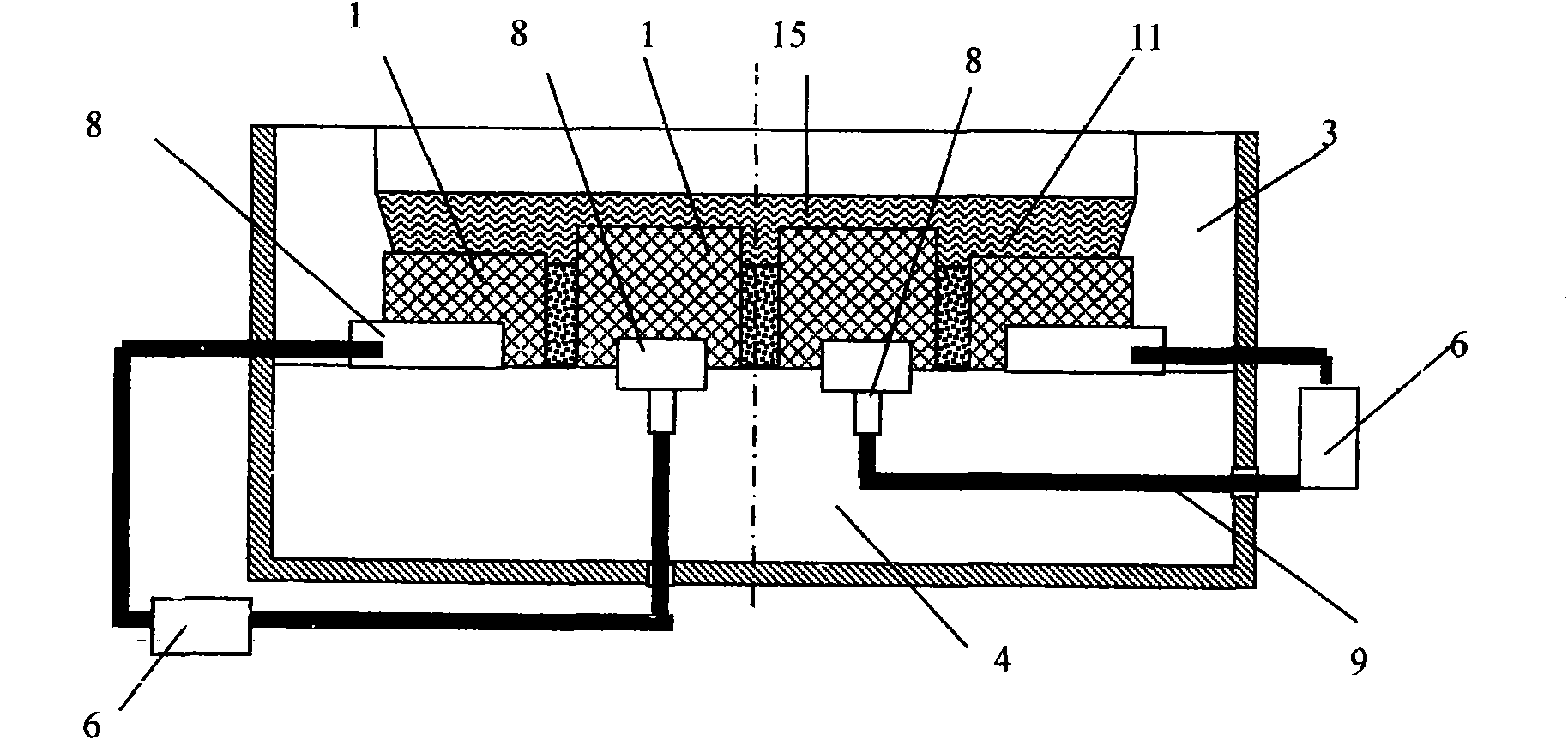

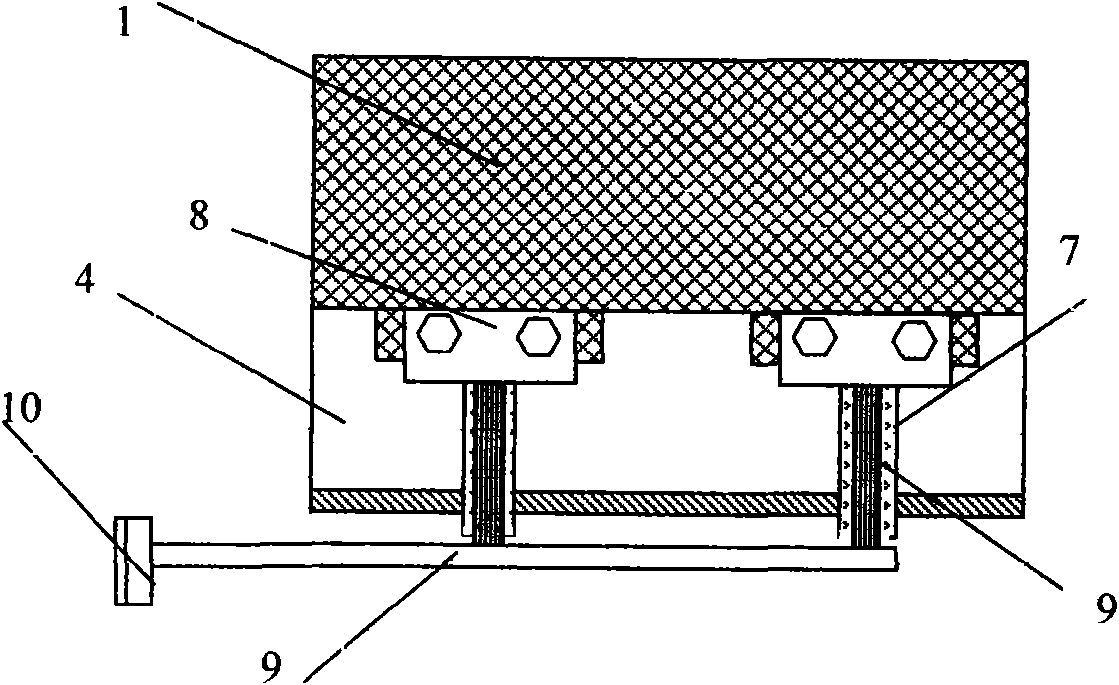

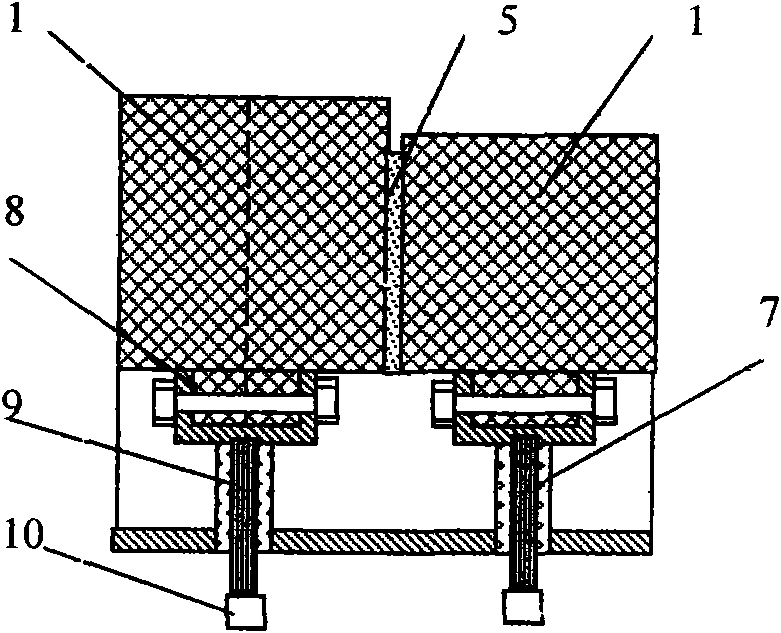

[0038] The lining structure of the cathode molten pool of the aluminum electrolytic cell is improved on the basis of the structure and materials of the cathode molten pool lining of the aluminum electrolytic cell currently in use, and its construction and masonry process can still be based on the current general use of the cathode molten pool lining of the aluminum-aluminum electrolytic cell According to the requirements and standards of the structure, the lining structure of the cathode molten pool of the aluminum electrolytic cell is composed of the electrolytic cell steel shell 2, the bottom insulation material layer 4, the side furnace wall 3, the cathode carbon block 1, the carbon metal cathode conductive connection line and the cathode The large busbar 6 and other components are constructed of materials, and its characteristic is that no cathode cathode steel rod groove is provided at the bottom of the cathode carbon block 1, and no cathode steel rod is provided at the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com