Bottom trough refractory material composite structure of aluminium cell cathode carbon block and manufacturing method thereof

A refractory material and cathode carbon block technology, applied in the field of aluminum electrolytic cells, can solve the problems of inability to ensure complete and in-place installation, and achieve the effects of reducing resistance, increasing conductive area, and reducing horizontal current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

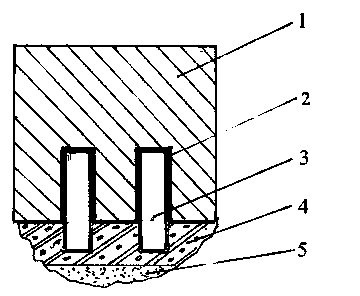

[0023] like figure 1 As shown, a combination structure of a tank-shaped refractory material for an aluminum electrolytic cell, including a cathode steel rod 3 protruding from the bottom surface of the cathode carbon block 1 and a refractory material at the bottom of the aluminum electrolytic cell, the cathode steel Between the rod 3 and the cathode carbon block 1 is a carbon tamping paste 2, and the upper surface of the refractory material is provided with a groove structure coupled with the cathode steel rod protruding from the bottom of the cathode carbon block 1, that is, the groove structure refractory material 4. The lower part of the channel structure refractory material 4 is an anti-seepage material layer 5 .

[0024] The manufacturing method of the trough-shaped refractory composite structure of the aluminum electrolytic cell is carried out according to the following steps:

[0025] First, construct the anti-seepage material layer 5 at the bottom of the aluminum elect...

Embodiment 2

[0030] The channel structure refractory structure 4 coupled with the cathode steel rod 3 protruding from the bottom of the cathode carbon block 1 of the aluminum electrolytic cell described in this embodiment is a prefabricated integral refractory material.

[0031] First, prefabricate an integral trough-shaped refractory structure 4 that can be tightly coupled with the surface of the bottom 1 of the cathode carbon block and the cathode steel rod 3 protruding from the bottom surface of the cathode carbon block 1 by pouring or tamping or other methods;

[0032] Afterwards, the prefabricated integral trough-type refractory structure 4 is assembled with the cathode carbon block 1 with cathode steel rod 3 protruding at the bottom;

[0033] Finally, the combined structure of the cathode carbon block 1, the cathode steel rod 3 and the trough-shaped refractory structure 4 is hoisted as a whole on the anti-seepage material at the bottom of the aluminum electrolytic cell or possibly oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com