Cathode structure capable of saving energy and homogenizing horizontal current in molten aluminium

A technology of horizontal current and cathode structure, which is applied to the cathode structure of the horizontal current of the homogenized aluminum liquid and the field of energy saving, can solve the problem of excessive fluctuation of the interface between the aluminum liquid and the electrolyte, increasing the pressure drop of the cathode carbon block group, and the instability of the electrolytic cell, etc. problems, to achieve uniform distribution of cathode current, reduce energy consumption per ton of aluminum, and prolong cell life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

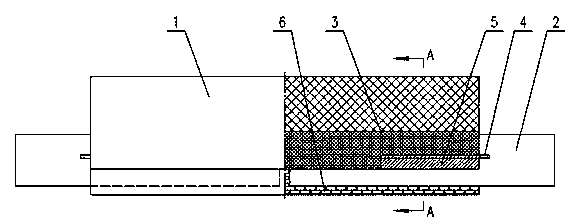

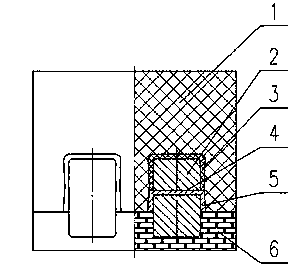

[0025] Such as figure 1 with 2 Shown in the present invention is an energy-saving cathode structure that homogenizes the horizontal current of molten aluminum. The conductive rod 2 protrudes from the bottom surface of the cathode carbon block 1, and the conductive rod 2 protruding from the bottom surface of the cathode carbon block 1 is surrounded by a coating material 6. The conductive rod 2 Divided into two parts by the separation seam 4 along the length direction, the conductive rod 2 above the separation seam 4 is connected with the cathode carbon block 1 with an electrical connector 3, and the conductive rod 2 below the separation seam 4 to the bottom surface of the cathode carbon block 1 is connected with an insulator 5 and The cathode carbon block 1 is connected, and the separation gap 4 is filled with insulating material. The conductive rod 2 is made of homogeneous material. The conductive rod 2 at the bottom of the carbon block 1 and the electrical connector 3 are ca...

Embodiment 2

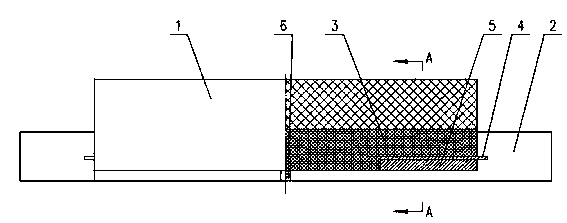

[0027] Such as Figure 3-4 Shown in the present invention is an energy-saving cathode structure that homogenizes the horizontal current of molten aluminum. The conductive rod 2 protrudes from the bottom surface of the cathode carbon block 1, and the conductive rod 2 protruding from the bottom surface of the cathode carbon block 1 is surrounded by a coating material 6. The conductive rod 2 Divided into two parts by the separation seam 4 along the length direction, the conductive rod 2 above the separation seam 4 is connected with the cathode carbon block 1 with an electrical connector 3, and the conductive rod 2 below the separation seam 4 to the bottom surface of the cathode carbon block 1 is connected with an insulator 5 and The cathode carbon block 1 is connected, and the separation gap 4 is filled with insulating material. The conductive rod 2 is composed of a multi-layer composite material 7. The cross section of the conductive rod 2 is semicircular. The number of the condu...

Embodiment 3

[0029] The cross section of the conductive rod 2 in Example 1 is circular, the number of the conductive rod 2 is 8, and the coating material 6 partially surrounds the conductive rod 2 protruding from the bottom of the cathode carbon block 1, and the bottom surface of the conductive rod 2 exposes the coating material 6. The electrical connecting body 3 is an adhesive, the material of the conductive rod 2 is copper, and the others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com