Aluminum electrolytic tank composite cathode structure containing a highly conductive skeleton network

A skeleton network and aluminum electrolytic cell technology, which is applied in the field of electrolytic cell composite cathode structure, can solve problems such as damage to the horizontal current cell, and achieve the effects of lower cell voltage, reduced horizontal current, and tight integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

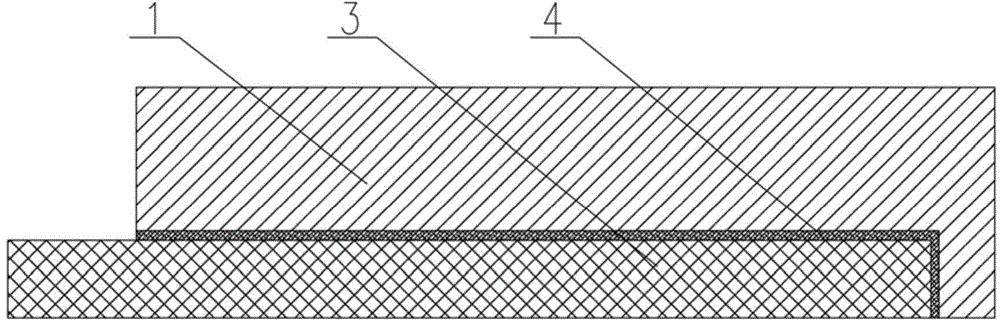

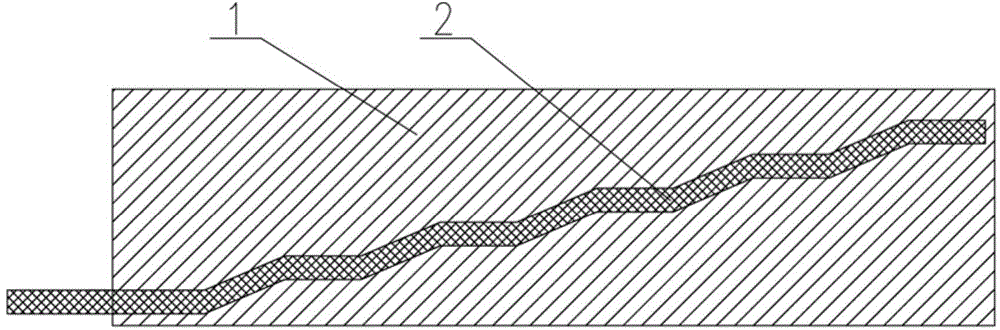

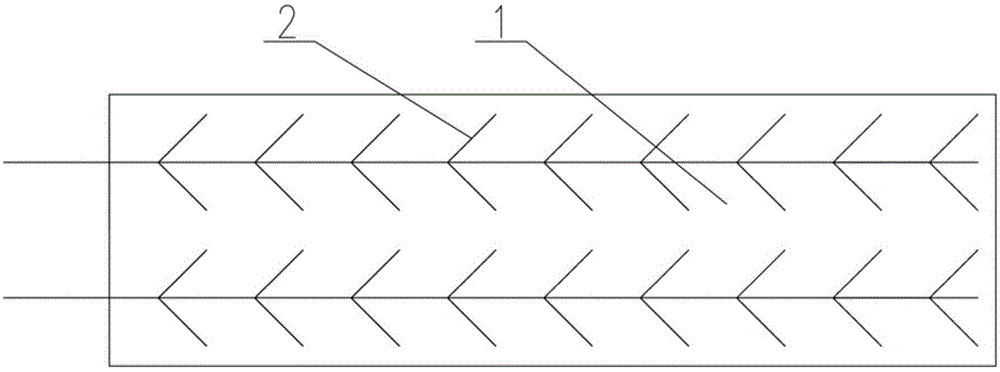

[0028] Such as figure 2 with image 3 Shown is the composite cathode adopting the herringbone cathode current collector framework 2 of the present invention, which is mainly composed of the cathode carbon block 1 and the herringbone cathode current collector framework 2, and the herringbone cathode current collector framework 2 is pre-embedded in the In the cathode carbon block 1, the close combination of the two is realized through the vibration forming and roasting of the cathode. In this embodiment 1, the total length of the cathode carbon block 1 is 3000-4000mm, the width is 400-700mm, and the height is 400-600mm; The length of the herringbone bifurcation on 2 is 50-100mm, the angle between two adjacent bifurcations is 90-120°, and the length of the trunk is 1500-2000mm; the cross-section of the herringbone cathode current collector skeleton 2 is circular or square , when the cross section of the herringbone cathode current collector skeleton 2 is square, the branch ske...

Embodiment 2

[0030] Such as Figure 4Shown is the composite cathode adopting the cross-shaped conductive current collector framework of the present invention, which is mainly composed of the cathode carbon block 1 and the cross-shaped conductive current collector framework 5. The cross-shaped conductive current collector framework 5 is pre-embedded in the cathode during the cathode manufacturing process. In the carbon block 1, the close combination of the two is realized through the vibration forming and roasting of the cathode. In this embodiment, the total length of the cathode carbon block 1 is 3000-4000mm, the width is 400-700mm, and the height is 400-600mm; The length of the cross-shaped bifurcation branch on the top is 50-100mm, and the adjacent cross-shaped conductive current collector skeleton 5 is connected to each other through the branches of the skeleton, and the length of the backbone of the cross-shaped conductive current collector skeleton 5 is 1500-2000mm; The cross-sectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com