Step type paste bundling cathode structure

A cathode structure and stepped technology, applied in the field of aluminum electrolysis, can solve the problems affecting the life of the tank, the damage of the tank lining, and the acceleration of the electrolyte flow rate, etc., and achieve the effects of simple construction, reduced horizontal current, and high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

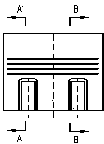

Image

Examples

Embodiment Construction

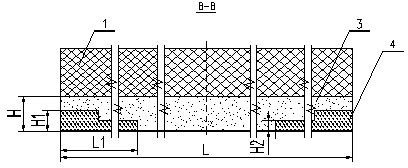

[0018] Implementation example of the present invention: a step-shaped paste surface 4 is set near the outlet end of the cathode steel rod 2, and the position of the step-form paste surface 4 is filled with a high-temperature-resistant insulating material, and the high-temperature-resistant insulating material is ceramic fiber cotton .

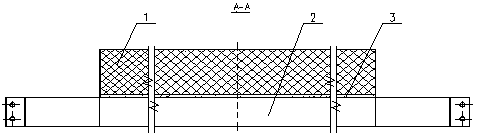

[0019] image 3 , 4 Among them, 1 is the cathode carbon block, 2 is the cathode steel rod, 3 is the paste surface of the steel rod, and 4 is the paste surface of the stepped shape.

[0020] Figure 4 middle, is the cathode length, The length of the high temperature resistant insulating material for the stepped shape of the filling, and The relationship is: .

[0021] is the total height of the paste, , are respectively the heights of the two steps of the filled step-shaped high-temperature-resistant insulating material, , and The relationship is:

[0022] , .

[0023] In the cathode structure, since the contact ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com