Method for preparing active monomer peonol from paniculate swallowwort root

A kind of active monomer, Xu Changqing's technology, applied in ether preparation, ether separation/purification, organic chemistry, etc., can solve the problems of no paeonol patent literature report, cumbersome preparation process, slow extraction speed, etc., and achieve low cost , wide application prospects and fast extraction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

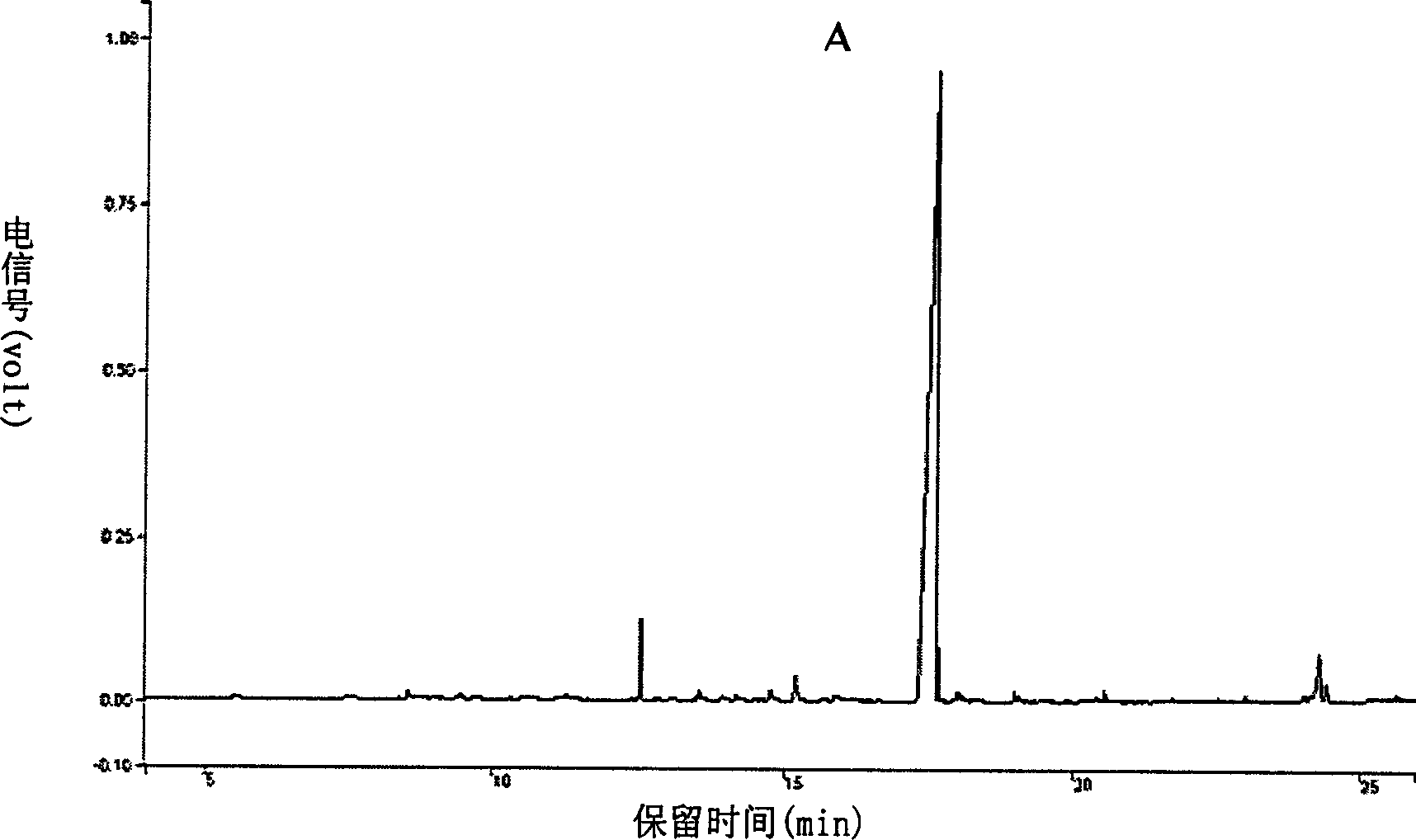

Embodiment 1

[0017] Bake 500g of the root of Xu Changqing at 60°C for 4 hours, crush it to 10 meshes, put the medicinal material powder into the reaction vessel of the ultrasonic extraction device, add 8 times the amount of petroleum ether with a boiling range of 30-60°C, and extract it ultrasonically for 2 hours (ultrasonic frequency 5000Hz). The filtered extract was refrigerated at 2°C for 4 hours to obtain pale yellow crystals, which were crude paeonol. Add 2 times the amount of 80% ethanol, control the temperature at 80°C, heat for 10 minutes, filter, and stand for crystallization for 5 hours to obtain nearly colorless crystals. The crystals were vacuum-dried at room temperature for 2 hours to obtain paeonol fine product, and the yield of paeonol was 1.24%.

Embodiment 2

[0019] Dry 500g of the root of Xu Changqing at 50°C for 4 hours, crush it to 30 meshes, put the medicinal material powder into the reaction vessel of the ultrasonic extraction device, add 9 times the amount of petroleum ether with a boiling range of 30-60°C, and extract it ultrasonically for 3 hours (ultrasonic frequency 5000Hz). The filtered extract was refrigerated at 3°C for 6 hours to obtain pale yellow crystals, which were crude paeonol. Add 3 times the amount of 80% ethanol, control the temperature at 80°C, heat for 10 minutes, filter, and stand for crystallization for 4 hours to obtain nearly colorless crystals. The crystals were vacuum-dried at room temperature for 2 hours to obtain paeonol fine product, and the yield of paeonol was 1.31%.

Embodiment 3

[0021] Dry 500g of the root of Xu Changqing at 40°C for 4 hours, crush it to 50 meshes, put the medicinal material powder into the reaction vessel of the ultrasonic extraction device, add 10 times the amount of petroleum ether with a boiling range of 30-60°C, and extract it ultrasonically for 4 hours (ultrasonic frequency 5000Hz). The filtered extract was refrigerated at 2°C for 5 hours to obtain pale yellow crystals, which were crude paeonol. Add 4 times the amount of 80% ethanol, control the temperature at 80°C, heat for 10 minutes, filter, and stand for crystallization for 5 hours to obtain nearly colorless crystals. The crystal was vacuum-dried at room temperature for 2 hours to obtain paeonol fine product, and the yield of paeonol was 1.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com