Waste slag fishing and conveying device for lead grid casting and use method thereof

A conveying device and waste slag technology, which is applied to casting equipment, process efficiency improvement, mechanical cleaning, etc., can solve the problems of lead explosion, slow removal, and large amount of generation, and achieve the effect of efficient slag removal and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

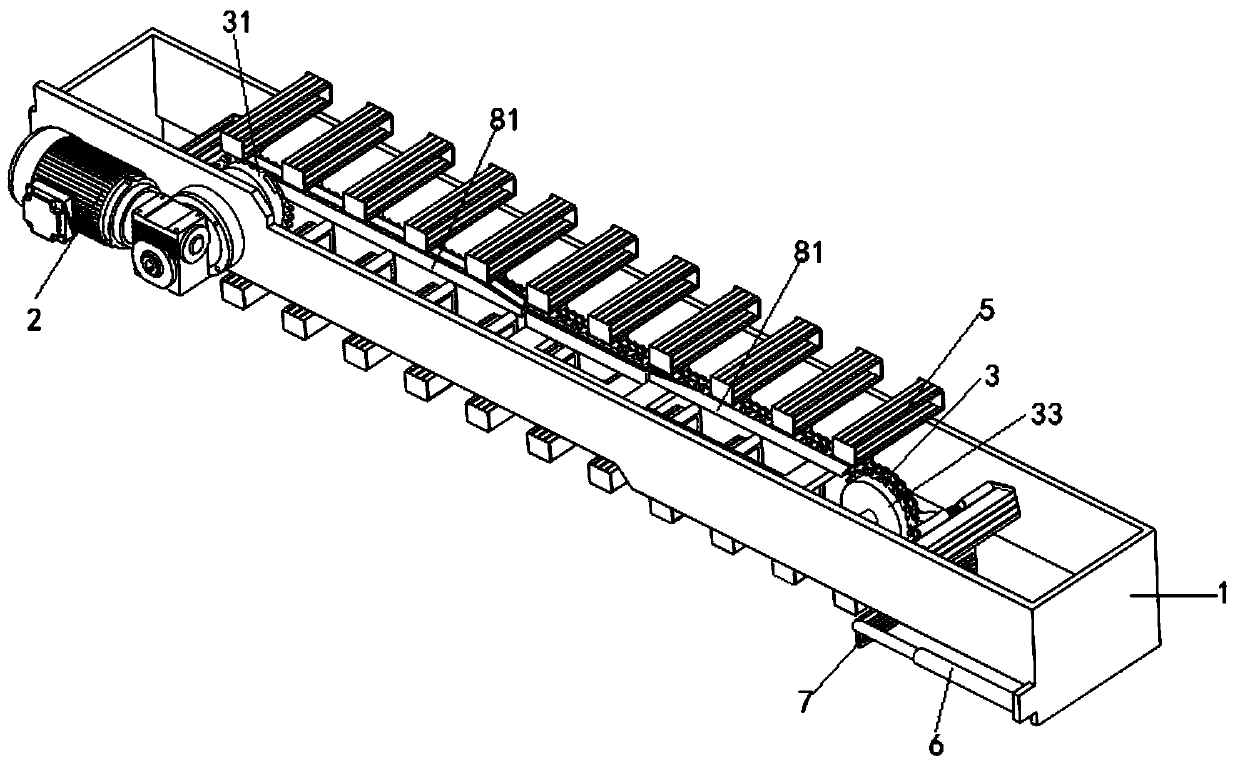

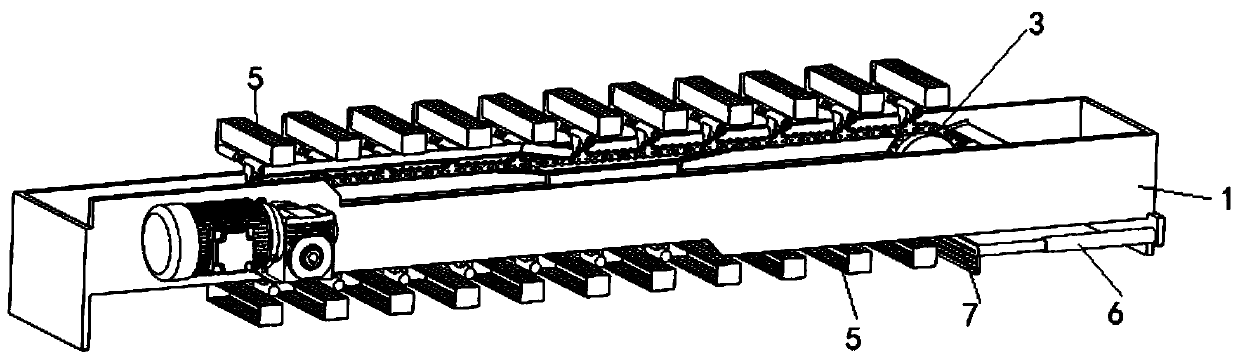

[0021] A waste slag fishing conveying device for lead grid melting and casting, such as figure 1 , figure 2 and image 3 As shown, the device is located in the lead grid melting and casting device, including a base frame 1, a geared motor 2 is installed on the outer surface of the rear side wall of the base frame 1, and the geared motor 2 is connected to the chain transmission mechanism 3, and the chain transmission mechanism 3 is on top. A number of fixed seats 4 are installed on each fixed seat 4, and a salvage seat 5 is installed and fixed on each fixed seat 4. At the same time, a hydraulic cylinder 6 is installed on the left side wall of the base frame 1, and a pusher is installed and fixed on the power output end of the hydraulic cylinder 6. plate 7;

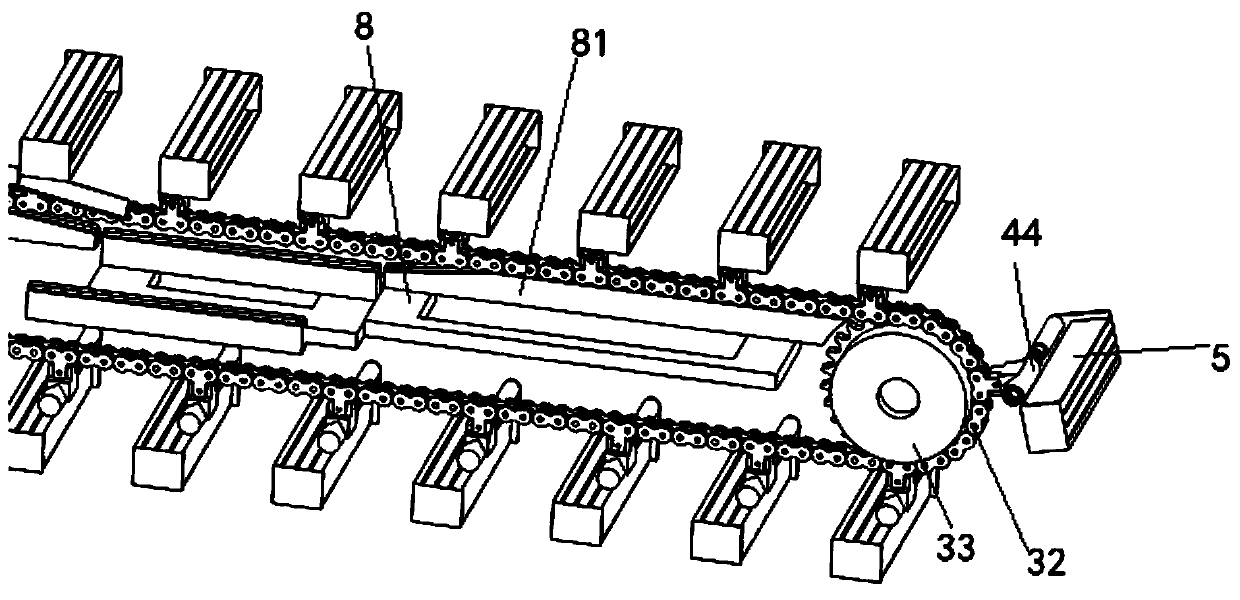

[0022] like Figure 4 , Figure 5 and Image 6 As shown, the chain transmission mechanism 3 includes a first transmission wheel 31 installed at the power output end of the reduction motor 2, the first transmission whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com